Rotor end ring

A rotor end ring and rotor technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of rotor end ring wear, hidden dangers, large space occupied by cooling fans, etc., and achieve good heat dissipation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments.

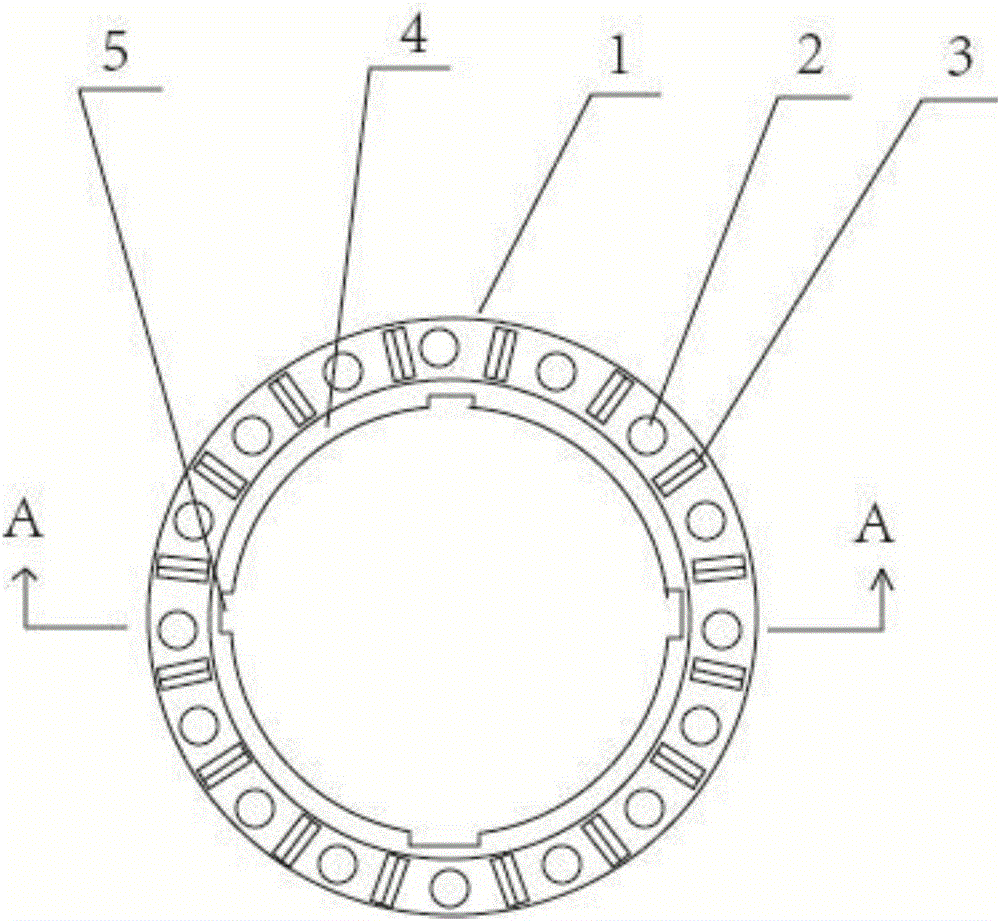

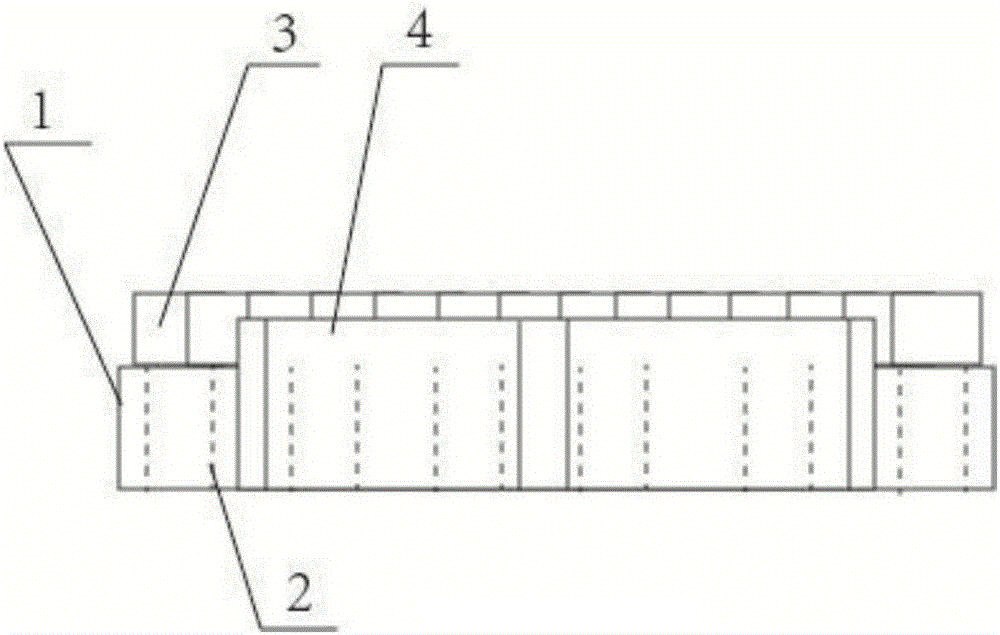

[0019] Such as figure 1 , 2 As shown, a rotor end ring includes a circular ring 1, the material of which is copper, and a plurality of circular through holes 2 are arranged on the circular ring 1, and the through holes 2 are evenly distributed on the circular ring 1. On the surface of the ring 1, the surface of the ring 1 between the adjacent through holes 2 is provided with rotor blades 3, the rotor blades 3 are in the shape of a three-sided column, and the quadrilateral surface of the three-sided column-shaped rotor blade 3 is welded Located on the surface of the circular ring 1, the circular ring 1 is located on the inner peripheral side and is provided with an outwardly protruding circular platform 4, and the circular platform 4 is arranged on any side of the circular ring 1. The circular rin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap