Multiple effect concentration swap de-scaling system

A subsystem, salt concentration technology, applied in multi-effect evaporation, multi-effect/segregation, control/manipulation systems, etc., to solve problems such as performance degradation, blocked flow paths, and reduced heat transfer effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

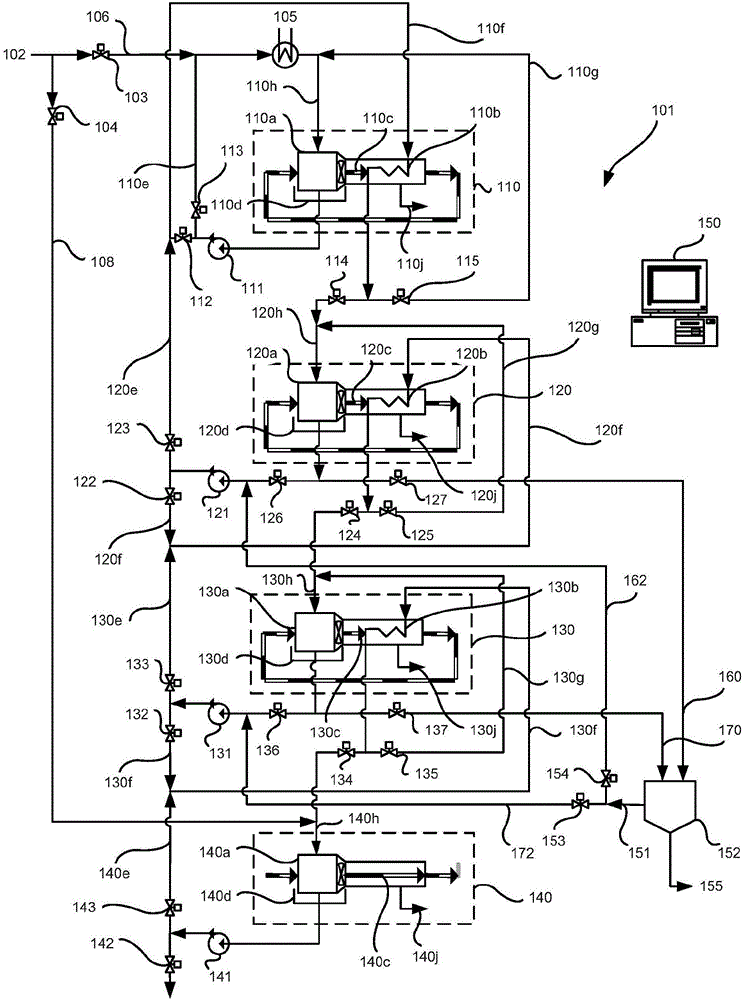

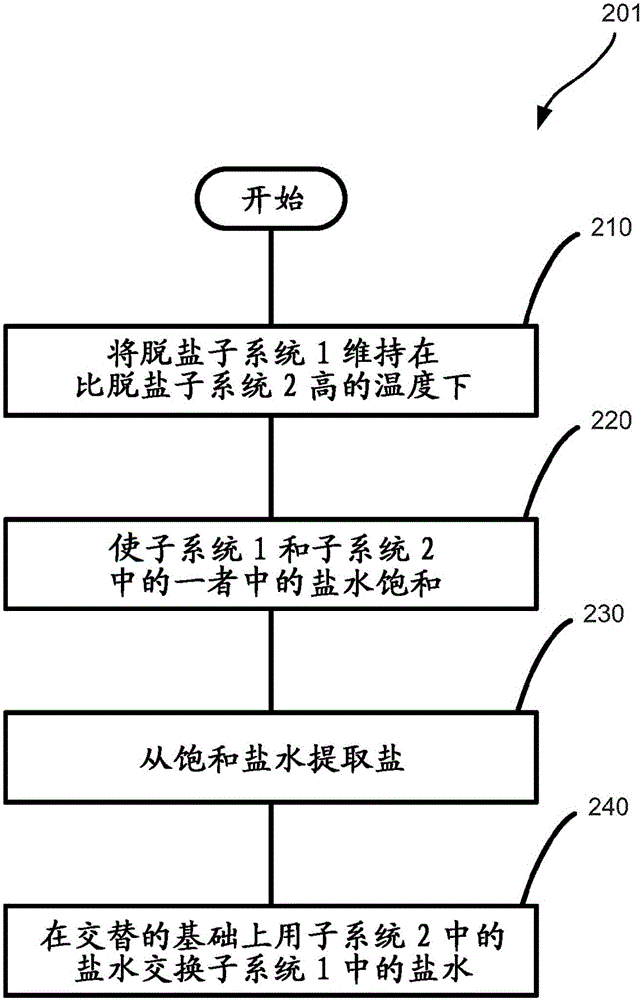

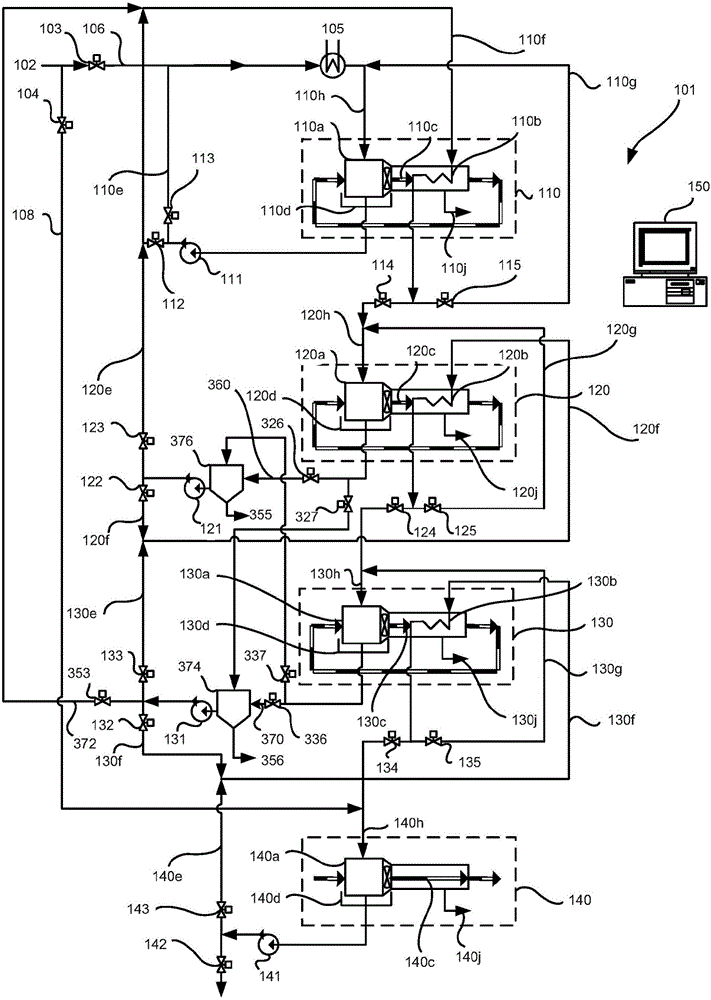

[0067] Embodiments described herein relate to a multiple-effect thermal desalination system configured to change the order in which physical thermal desalination subsystems are applied in the multiple-effect thermal desalination system. The term "multi-effect thermal desalination system" is used herein to describe a thermal desalination system that includes more than one thermal desalination subsystem and thus includes more than one associated desalination process stage. One exemplary embodiment of the systems and methods disclosed herein is based on a multiple-effect humidification-dehumidification (HDH) thermal desalination system. At least some of the embodiments described herein are directed to reducing the frequency or need to wash a desalination system, as well as mitigating the adverse consequences of adding fresh water to a solution being concentrated.

[0068] figure 1 A first exemplary embodiment of a four-stage multi-effect HDH thermal desalination system 101 is sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com