Nut picking manipulator

A technology of manipulators and nuts, which is applied to picking machines, agricultural machinery and implements, harvesters, etc., and can solve problems such as low picking efficiency, limited picking height, and waste of manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail below in conjunction with accompanying drawing:

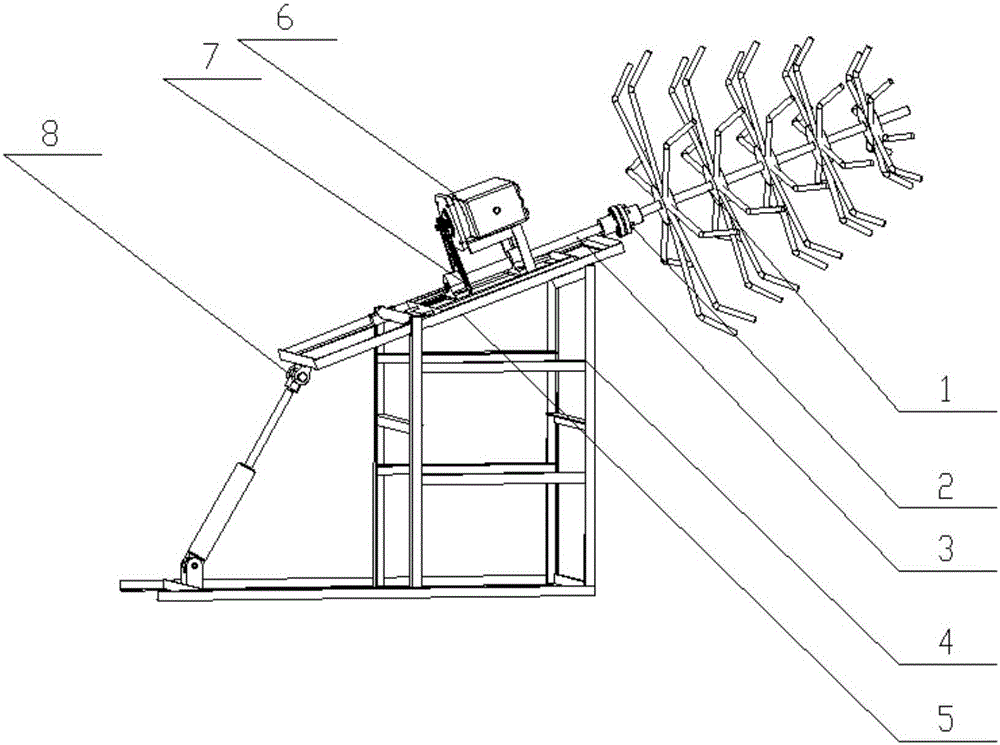

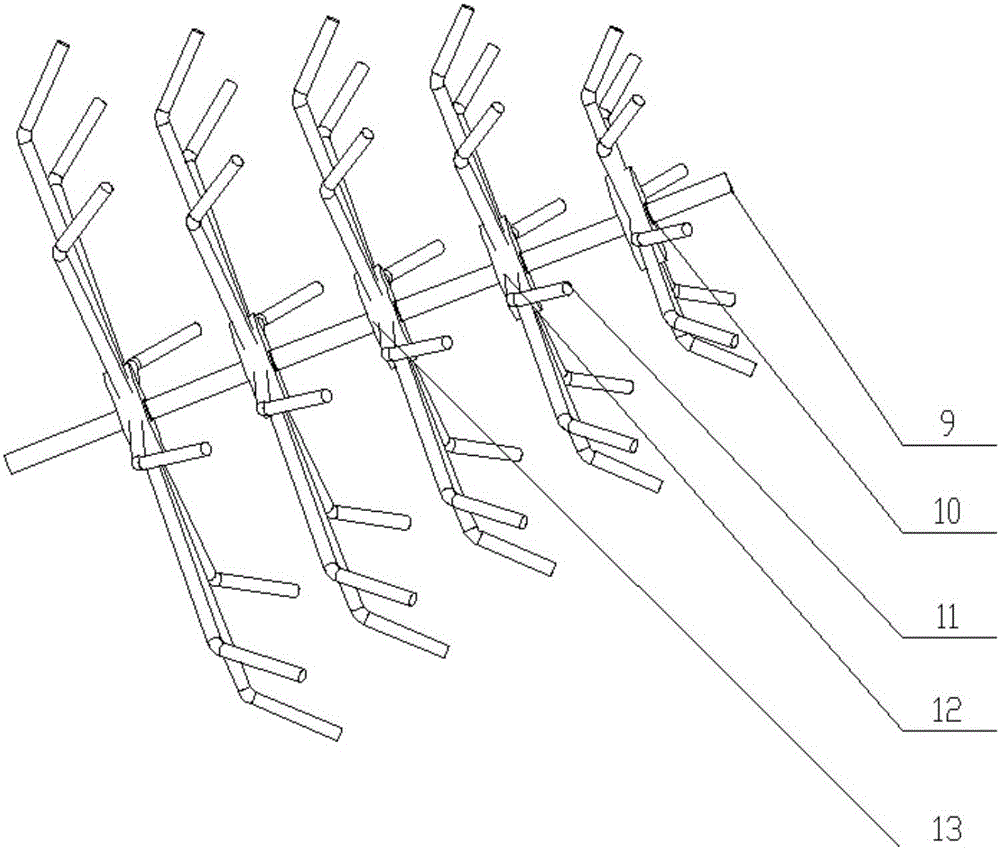

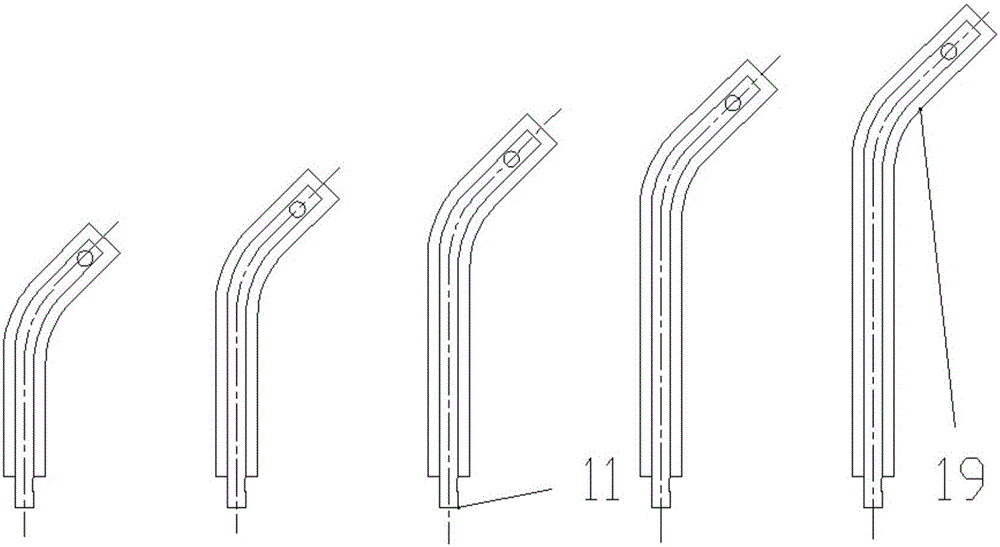

[0027] A kind of manipulator for picking nuts, comprising a frame 4, two base angle steels 23 with a length of 1.6m placed horizontally and parallel are welded to the left and right ends of a connecting angle steel 22, the connecting angle steel 22 is located at the right end of the base angle steel, at a distance from the base An angle steel seat 24 is welded at 160 mm from the left end of the angle steel 23, and a hydraulic cylinder tail support seat 25 is hinged in the middle of the angle steel seat 24. The cylinder barrel of the hydraulic cylinder 8 is connected to the hydraulic cylinder tail support seat 25 by means of bolt connection, thereby completing Hinged with frame 4 ends, the middle part of two base angle steels 23 is vertically welded two mutually parallel short support angle steels 27, and two mutually parallel long support angle steels 26 are vertically welded o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com