Water purification filter for water-saving irrigation system

An irrigation system and water purification technology, applied in the field of filters, can solve the problems of increasing the cost of filter manufacturing and use, achieve the effect of easy operation and use, and realize backwashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

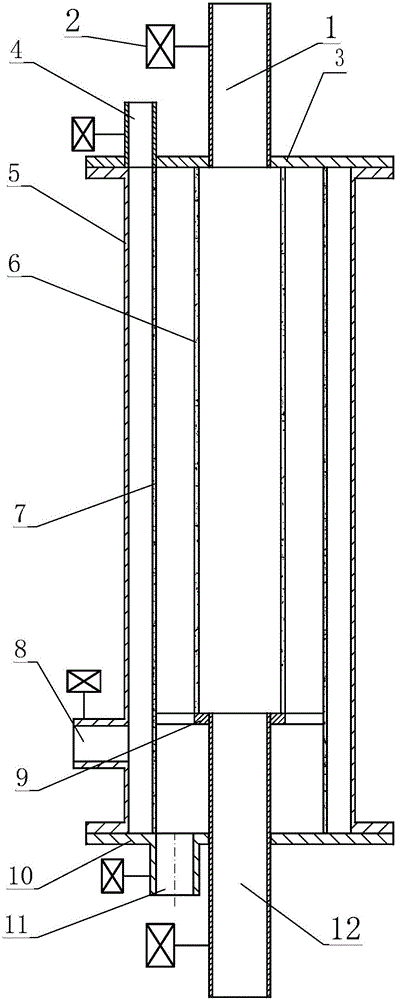

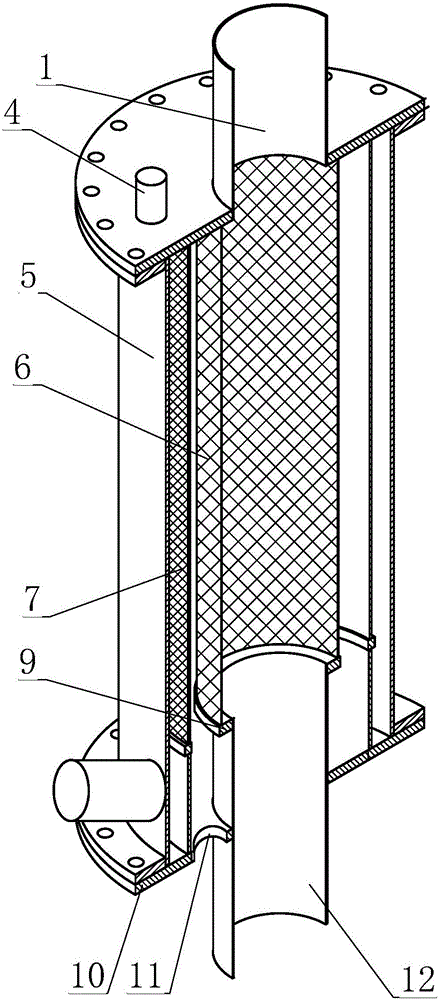

[0016] Embodiment 1: refer to figure 1 , figure 2 , is a structural schematic diagram of Embodiment 1 of the present invention, including a cylindrical housing (5) provided with a water inlet (1) and a water outlet (8), the water inlet (1) is located on the upper part of the housing (5), and the housing Between the water inlet (1) and the water outlet (8) in (5), two layers of filter screens of different specifications are arranged in concentric circles, i.e. a large size filter screen (6) and a small size filter screen (7). The standard filter screen (6) is arranged on the side of the water inlet (1) in the center of the housing (5), and the small size filter screen (7) is arranged on the periphery of the large size filter screen (6), that is, on the side of the water outlet (8). At the same time, a sewage outlet is provided on the side of the water inlet (1) and between the two layers of filter screens, that is, a sewage outlet A (12) is provided on the side of the water i...

Embodiment 2

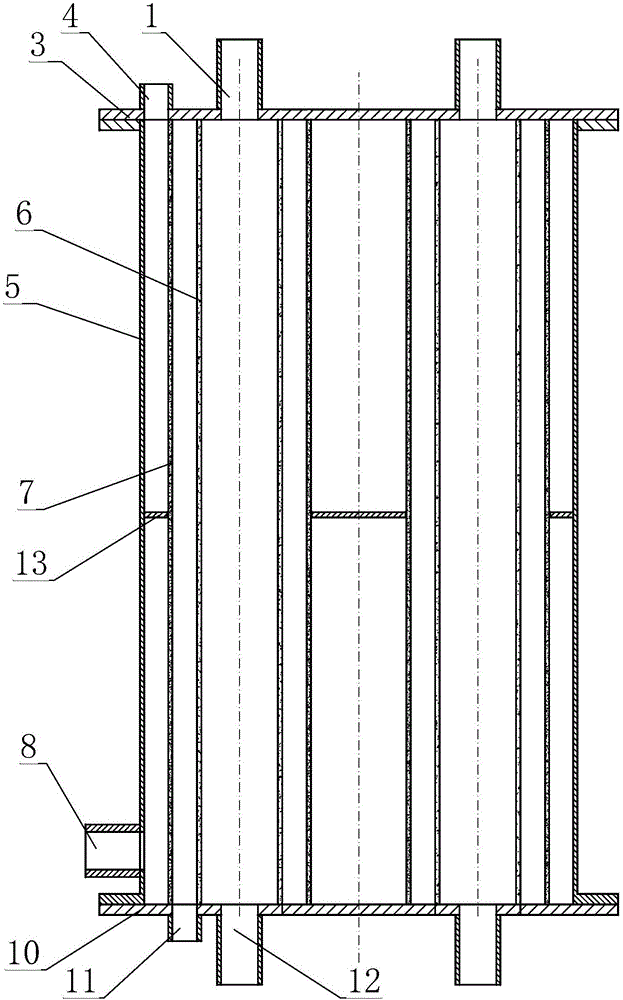

[0017] Embodiment 2: refer to Figure 3 ~ Figure 5 , is a structural schematic diagram of Embodiment 2 of the present invention. Compared with Embodiment 1, the difference of this embodiment is that: the two layers of filter screens of different specifications form a single filter unit, and in the housing ( 5) A plurality of filter units are arranged inside, and each filter unit is provided with a water inlet (1) and two sewage outlets.

Embodiment 3

[0018] Embodiment 3: refer to Figure 6 , is a structural schematic diagram of Embodiment 2 of the present invention. Compared with Embodiment 2, the difference of this embodiment is that a layer of filter net is also arranged on the periphery of a plurality of filter units composed of two layers of filter nets of different specifications. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com