Membrane transfer coating MBR membrane and preparation method thereof

A technology of membrane transfer and transfer membrane, which is applied in the field of water treatment, can solve the problems of poor mechanical properties of MBR membrane components, and achieve the effects of avoiding instability, controllable thickness, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

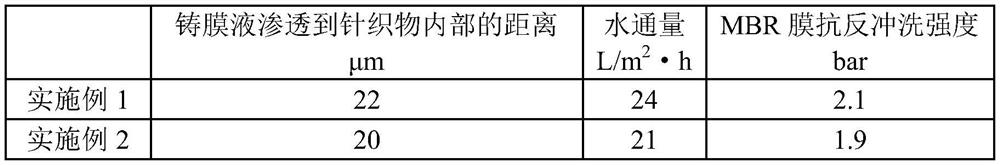

Embodiment 1

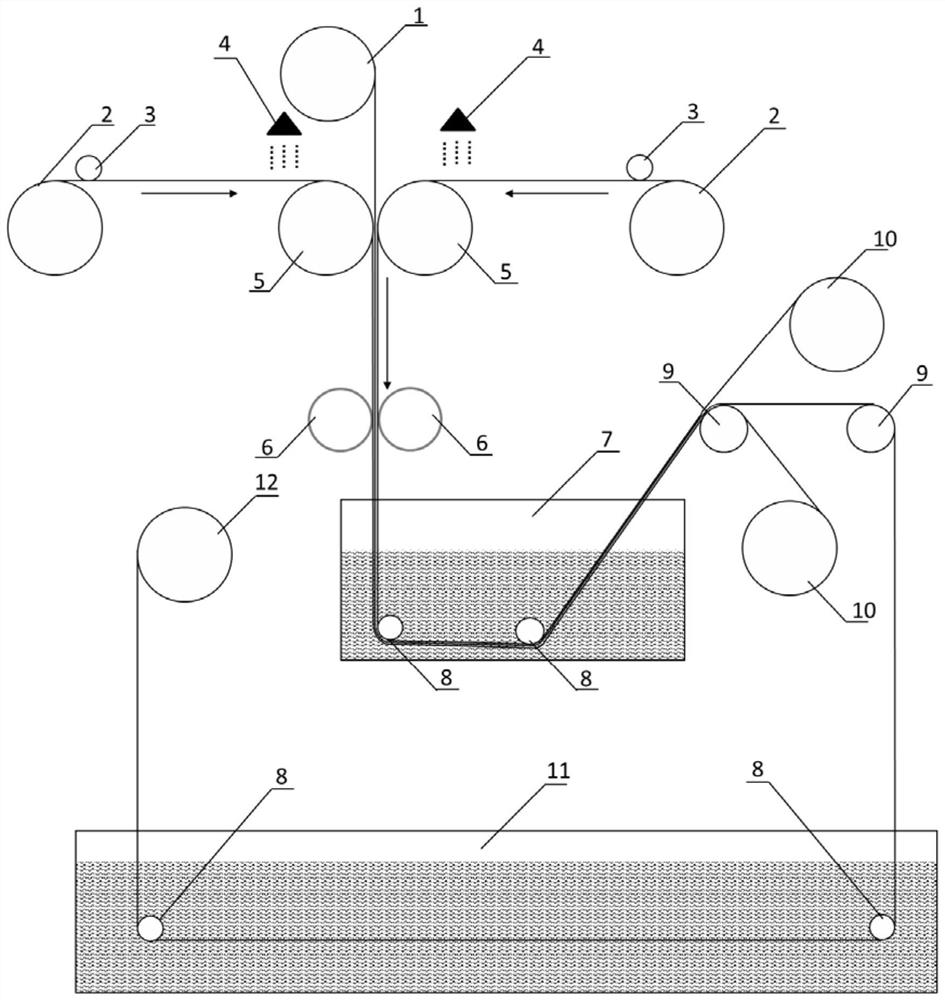

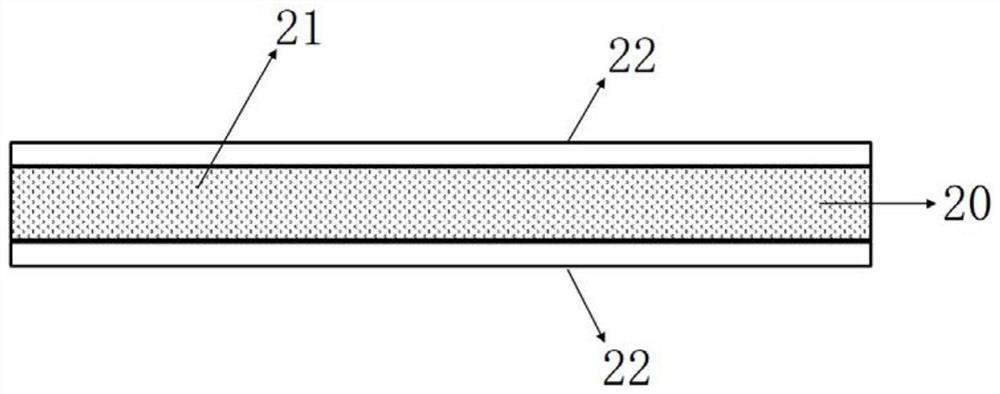

[0036] A kind of preparation method of film transfer coating MBR film:

[0037] Step 1: Prepare casting solution: uniformly mix 20 parts of PVDF powder, 5 parts of polyethylene glycol 1000, 3 parts of acrylate and 72 parts of dimethylacetamide, then stir at a constant speed for 6 hours in a water bath at 80°C, and then 150-mesh screen filtration, vacuum defoaming treatment to obtain refined casting liquid;

[0038] Step 2: Coating of MBR film: Coat the prepared casting solution on two 0.2mm 304 stainless steel belt transfer films synchronously with a comma knife coater on the horizontal upper surface, and the coating speed is 0.2m / s, the double-sided coating speed difference is not more than ±2%, the coating thickness is 200 μm, and the double-sided coating drive shaft, roller pressing shaft, and interval knitted fabric unwinding shaft are interlocked at the same speed;

[0039] Step 3: Spraying the adhesion promoter: Spray the 0.5% acrylate adhesion promoter on the surface ...

Embodiment 2

[0043] A kind of preparation method of film transfer coating MBR film:

[0044] Step 1: Prepare casting solution: uniformly mix 20 parts of PVDF powder, 5 parts of polyethylene glycol 1000, 3 parts of acrylate and 72 parts of dimethylacetamide, then stir at a constant speed for 6 hours in a water bath at 80°C, and then 150-mesh screen filtration, vacuum defoaming treatment to obtain refined casting liquid;

[0045] Step 2: Coating of MBR film: Coat the prepared casting solution on two 0.2mm 304 stainless steel belt transfer films synchronously with a comma knife coater on the horizontal upper surface, and the coating speed is 0.2m / s, the double-sided coating speed difference is not more than ±2%, the coating thickness is 200 μm, and the double-sided coating drive shaft, roller pressing shaft, and interval knitted fabric unwinding shaft are interlocked at the same speed;

[0046] Step 3: Spraying the adhesion promoter: Spray the acrylate adhesion promoter with a concentration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com