A high-voltage driving circuit device with blocking particles

A high-voltage drive circuit and particle technology, which is applied in the direction of logic circuit connection/interface layout, power supply technology, electrostatic separation, etc., can solve the problems of poor performance of high-voltage drive circuits, influence, and temperature rise of high-voltage drive circuits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, content of the invention will be further described:

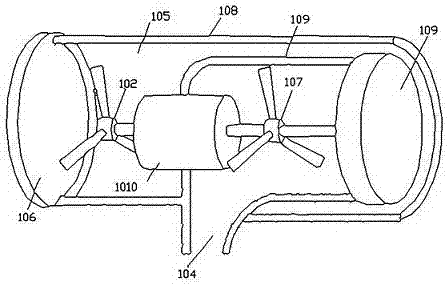

[0014] refer to figure 1 , figure 2 As shown, there is a high-voltage drive circuit device for blocking particulate matter, including a high-voltage drive circuit, and the high-voltage drive circuit is placed in the impurity removal device. In addition, the impurity removal device includes a first hollow cover 108 and a first hollow cover. The second hollow cover 109 in the cover 108, the motor 1010 is installed in the first hollow cover 108, the first air intake fan 102 is installed on the motor shaft of the motor 1010, the first One end of the hollow cover body 108 is an air inlet, and the other end of the first hollow cover body 108 is an outlet for particulate impurities, and the outlet for particulate impurities is covered with a cover 106 with a mesh. One end of the second hollow cover body 109 is an air inlet, and the air inlet position of the second hollow co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com