Material-removing type screen tensioning beam

A technology of screen mesh and beam tightening, applied in the direction of filter screen, solid separation, grille, etc., can solve the problem of unreliable hook plate hooking, etc., and achieve the effect of convenient cleaning and reliable hooking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

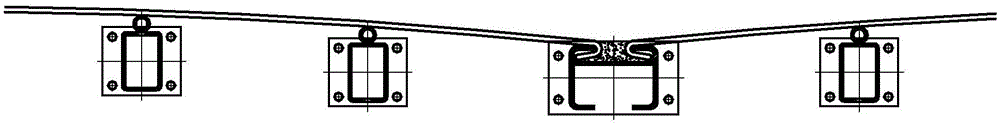

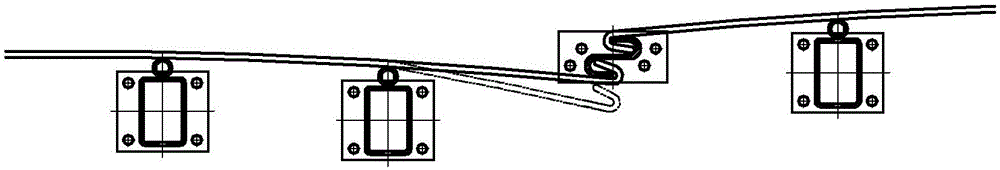

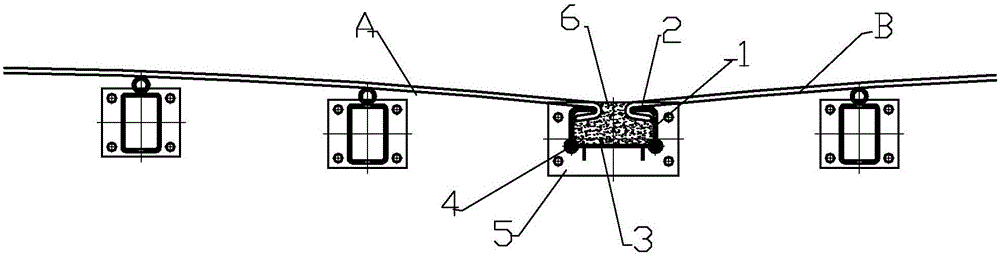

[0011] Such as image 3 Shown: a material-cleaning screen tensioning beam, including two baffles 1 arranged at intervals, the top edges of the two baffles 1 are respectively connected with hook plates 2 facing inward, each baffle 1 and The hook plate 2 at the top edge of the baffle plate 1 is integrally bent and formed.

[0012] There is a gap 6 between the two hook plates 2, and the gap 6 can be used for the hooks at the ends of the screen A and the screen B to enter and be hooked with the hook plate 2; between the bottom edges of the two baffle plates 1 A partition door 3 that can be opened and closed is provided, one end of the partition door 3 is hinged on one baffle 1 through a hinge shaft, and the other end is installed on the other baffle 1 through a latch 4; the tension beam Connecting flanges 5 are respectively fixed at both ends of the connecting flange 5, and are installed on the side plate through the connecting flanges 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com