Dual waste scrap treatment device for numerically controlled lathe

A technology of CNC lathes and processors, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of flying waste, stuck and unable to open, unable to remove waste well, etc. , to achieve the effect of comprehensive cleaning function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

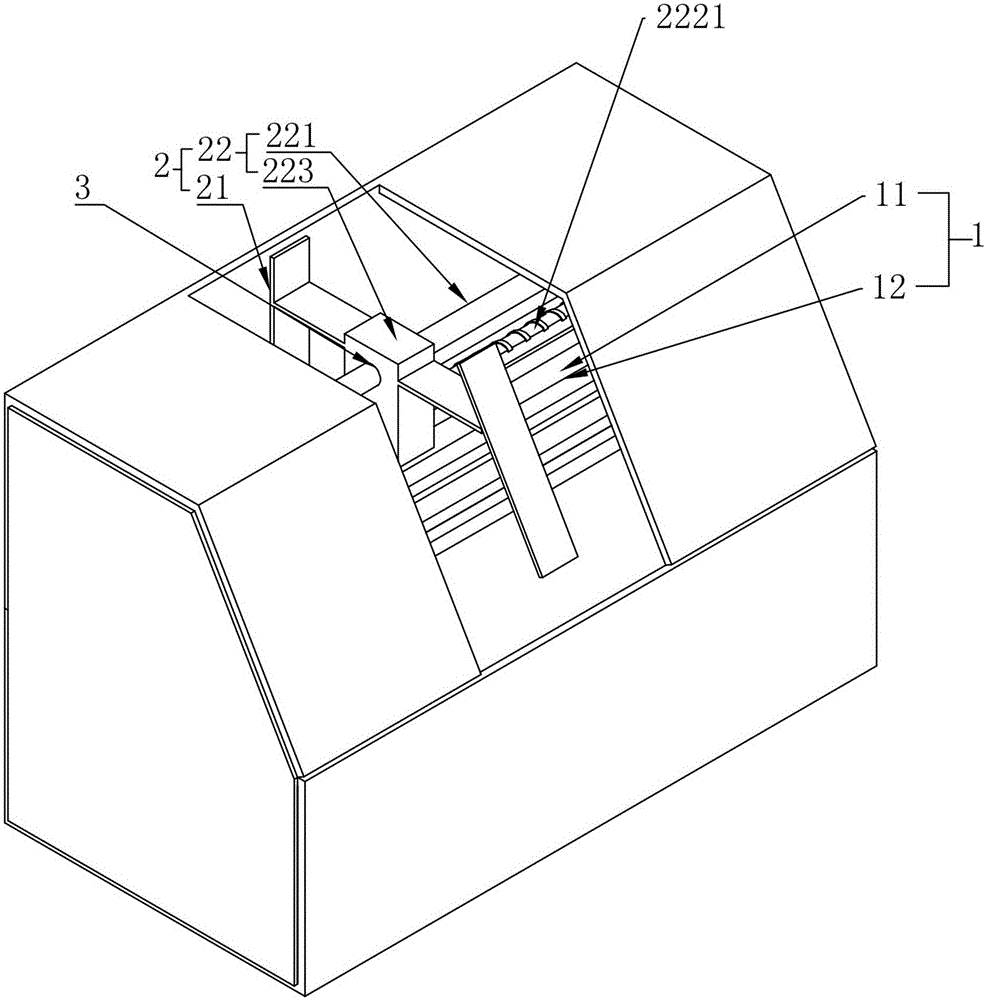

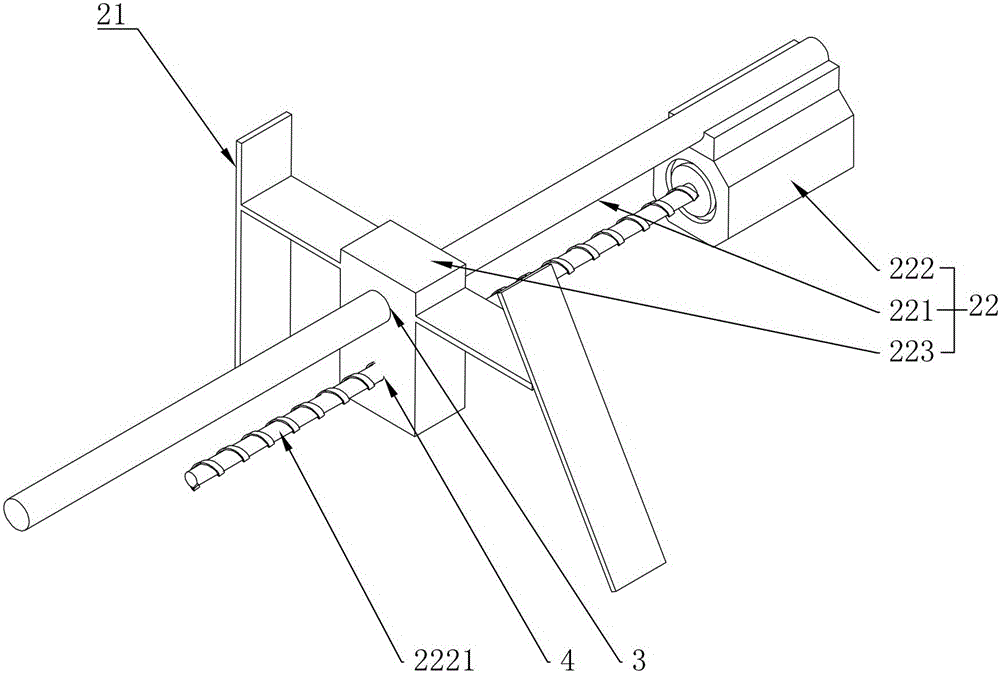

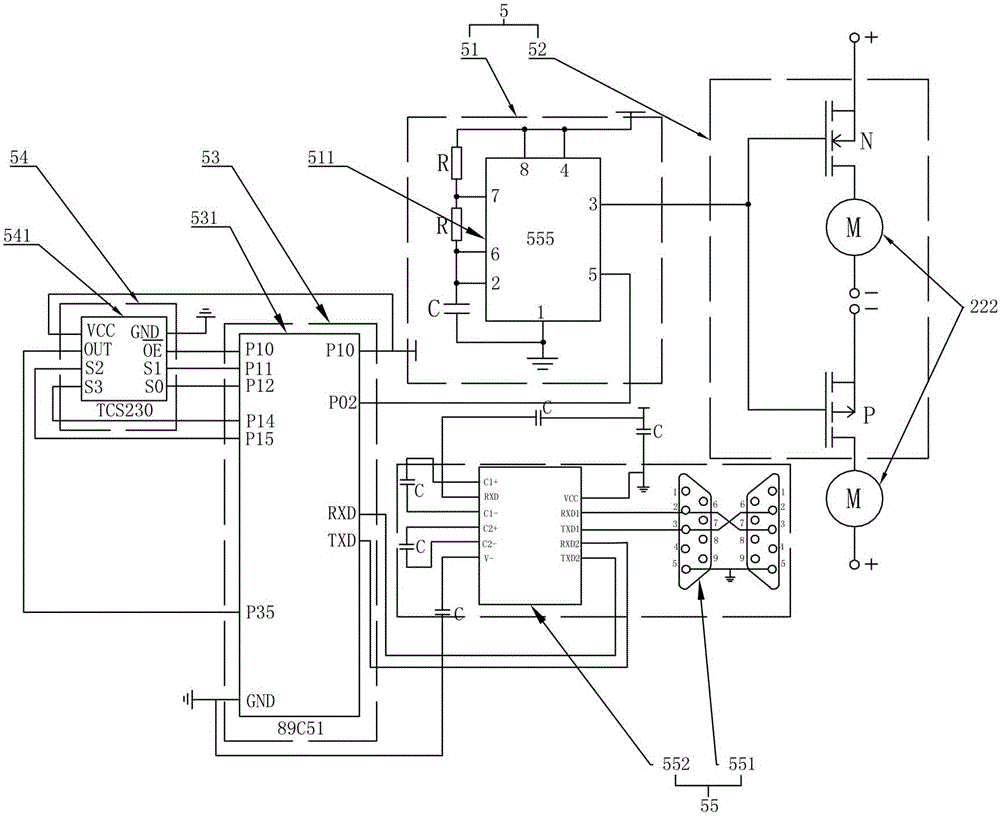

[0014] refer to Figures 1 to 4As shown, a double waste processor for a CNC lathe in this embodiment includes a bottom chip removal mechanism 1 and a side wall chip removal mechanism 2, and the bottom chip removal mechanism 1 includes a double waste chip that sends waste chips out of the CNC lathe The conveyor belt 11 of the processor and the chip discharge groove 12 for receiving waste chips, the conveyor belt 11 is used as the groove bottom of the chip discharge groove 12, the side wall chip removal mechanism 2 is arranged above the chip discharge groove 12, and the side wall The wall chip removal mechanism 2 includes a scraper 21 attached to the casing of the CNC lathe frame and a drive assembly 22 that drives the scraper 21 to move back and forth. Shaft 221, a driving motor 222 fixed on one end of the fixed shaft 221, and a slider 223 sliding on the fixed shaft 221, the slider 223 is fixed with the scraper 21, and a screw is coaxially fixed on the rotating shaft of the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com