Telescoping guard for vertical lathe ram

A vertical lathe, telescopic technology, applied in the direction of maintenance and safety accessories, metal processing machinery parts, metal processing equipment, etc., can solve the problems of easy vibration of the protective cover, inconvenient operation and installation, and affect the use of the lathe, and achieve the overall Coordinated appearance, light weight, easy disassembly and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

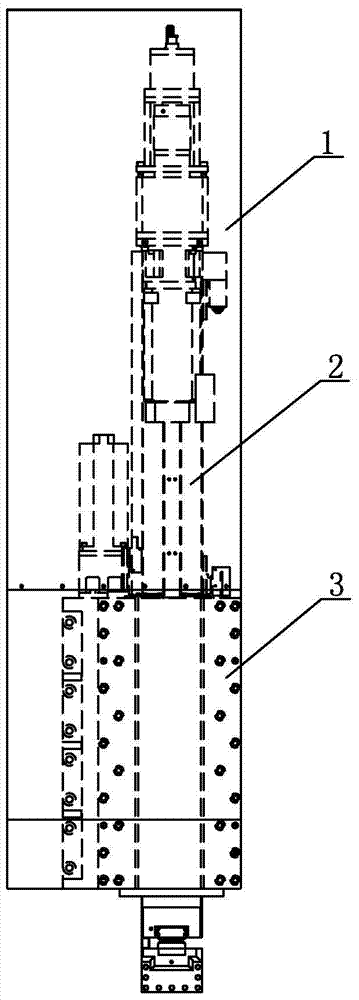

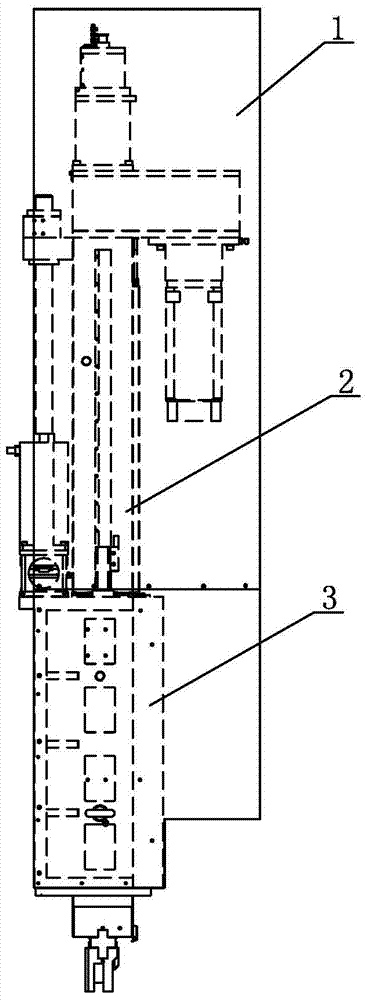

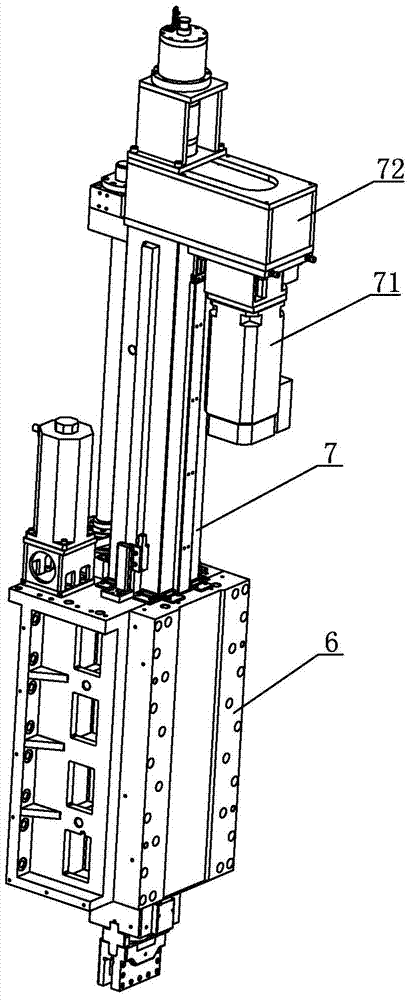

[0031] The telescopic protective cover of the vertical lathe ram of Embodiment 1, as shown in the figure, includes a first cover body 1, a second cover body 2 and a third cover body 3, and the first cover body 1 is detachably installed and fixed on On the saddle 6, the first cover body 1 is close to and covered on the front side of the saddle 6, the second cover body 2 is detachably mounted and fixed on the ram 7, and the second cover body 2 is set on the ram 7 The front wall of the second cover 2 is provided with a notch 4, the motor 71 and the motor seat 72 of the ram 7 protrude from the notch 4, and the third cover 3 is detachably mounted and fixed on the second cover. 2, the third cover body 3 is set on the outside of the motor 71 and the motor base 72, the inside of the second cover body 2 is fixed with a slider 51, the outside of the first cover body 1 is fixed with a guide rail 52, and the slider 51 is assembled on on the rail 52.

Embodiment 2

[0032]The telescopic protective cover of the vertical lathe ram in embodiment 2 specifically defines the structure of the protective cover on the basis of embodiment 1, as shown in the figure, including a first cover body 1, a second cover body 2 and a first cover body Three covers 3; the first cover 1 includes a first front panel 11, a first side panel 12 and a first bottom panel 13 connected together, the first side panel 12 is two pieces, and the two first side panels 12 are arranged symmetrically On both sides of the first front plate 11, the first cover body 1 is provided with two first reinforcing ribs 14, the two first reinforcing ribs 14 are arranged in parallel up and down on the back side of the first cover body 1, and the guide rails 52 are two , the two guide rails 52 are respectively fixed on the fronts of the two first side plates 12; the first front plate 11, the two first side plates 12 and the first bottom plate 13 are respectively fixedly connected with the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com