A pipe lifting platform for subsea pipeline maintenance

A technology for submarine pipelines and platforms, which is used in pipeline laying and maintenance, pipes/pipe joints/fittings, machinery and equipment, etc. The effect of stress and increased safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

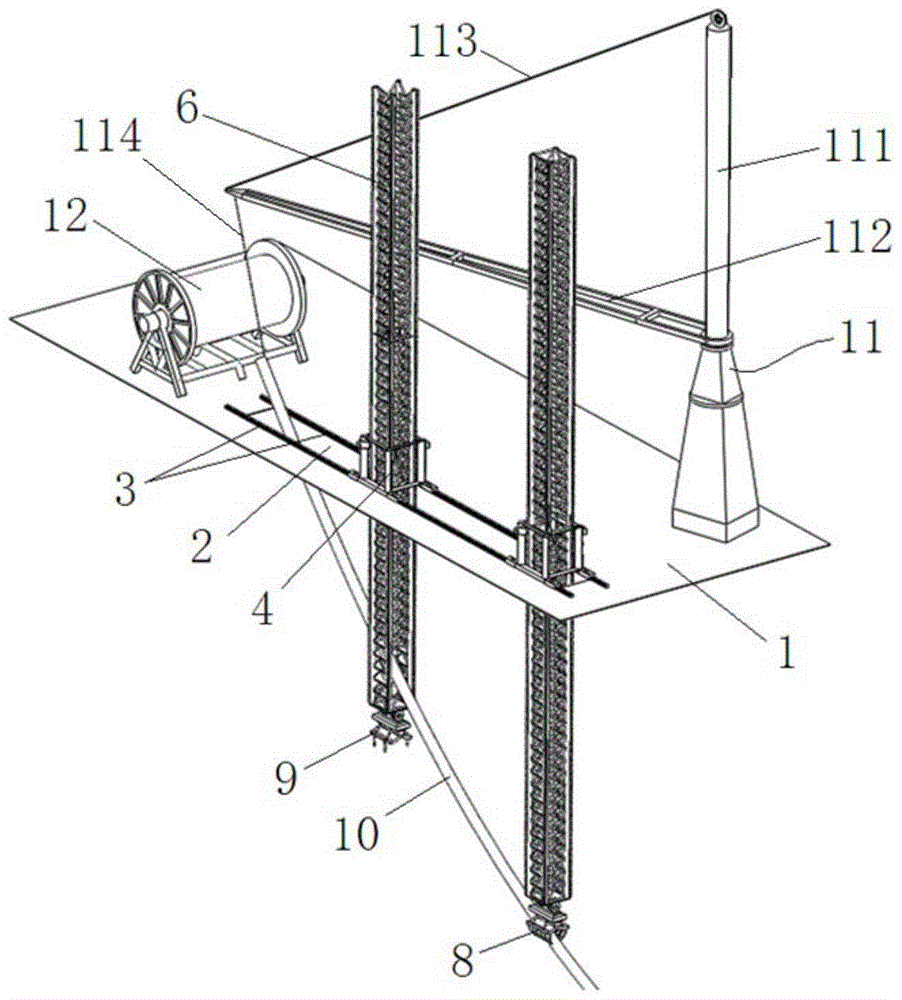

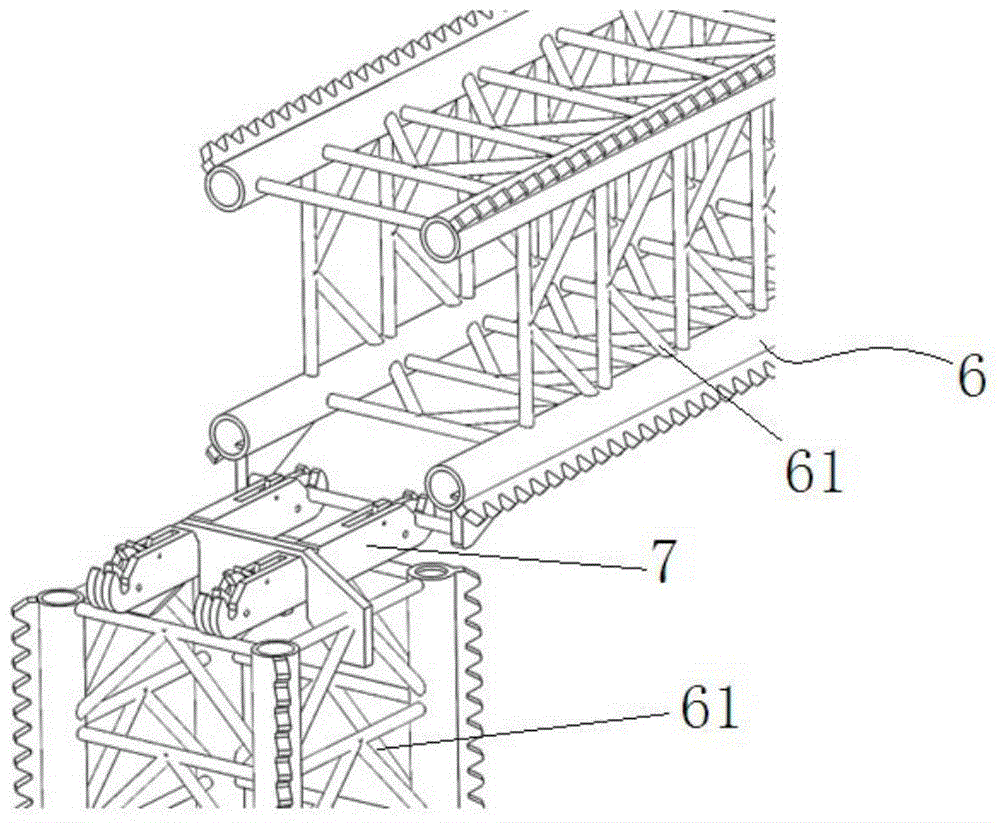

[0028] Such as figure 1 As shown, the present invention includes a platform deck 1, a rectangular moon pool 2 is arranged on the platform deck 1, and a pair of slide rails 3 are arranged in parallel on both side edges of the moon pool 2, and the two slide rails 3 are slidably Two pile-fixing frames 4 are arranged, and each pile-fixing frame 4 can be vertically lifted and connected to a pipe truss 6 . Every pipe lifting truss 6 comprises more than two truss single sections 61 (such as figure 2 As shown), every two truss single sections 61 are connected by at least one clamping device 7 . It is a preferred embodiment that each pipe lifting truss 6 includes two truss single sections 61 .

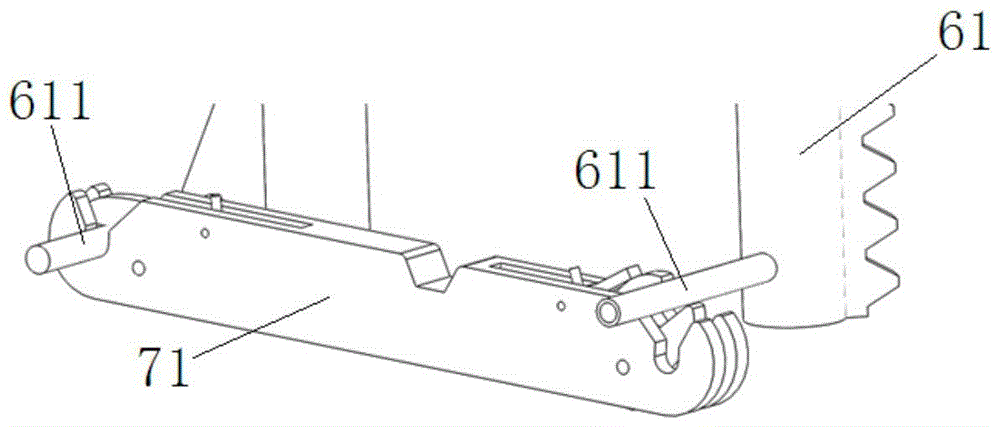

[0029] Such as Figure 2-4 As shown, the card holding device 7 includes a fixed frame 71, which is fixedly connected to the top of a single truss section 61, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com