A conductive porous lightweight aggregate loaded with modified agar gel, its preparation method and application

A technology of agar gel and lightweight aggregate, which is applied in the field of conductive concrete, can solve the problems of small length-to-diameter ratio, reduced concrete strength, and high price, and achieve the effects of reduced resistivity, lower resistivity, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

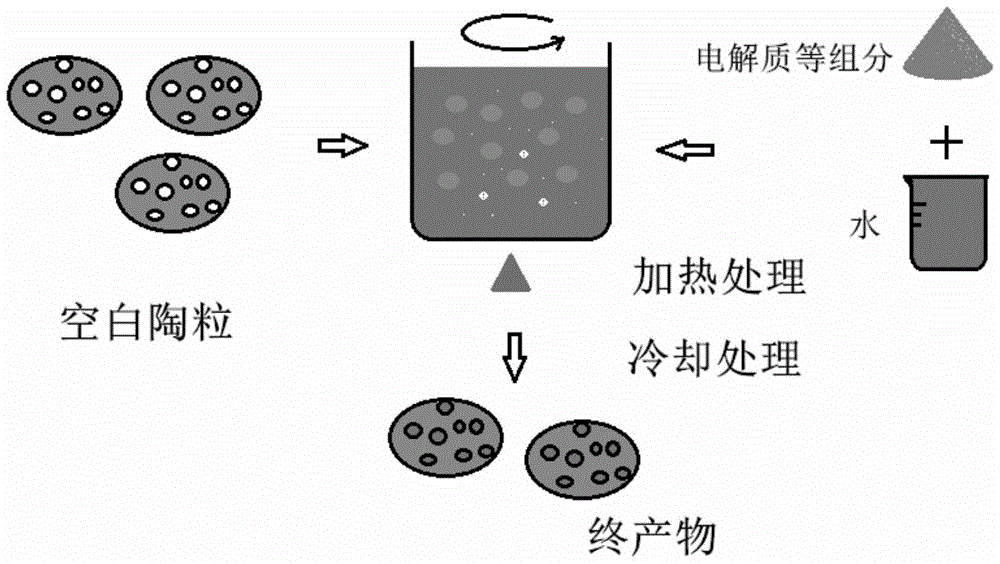

[0027] Conductive lightweight porous ceramsite loaded with modified agar is prepared by immersing thermally modified agar aqueous solution, and cement-based material products for conductivity or antistatic are prepared by this method:

[0028] (1) According to the mass ratio of 100:6:0.6:3, weigh water and NaNO 2 , NaOH and agar powder;

[0029] (2) Add the agar powder into the water first, keep stirring and heat until boiling until the agar is completely dissolved, then add NaOH, NaNO 2 Add the weighed modified electrolyte in the following order, keep the solution temperature above 90°C and keep stirring for 30s to prepare the modified agar aqueous solution;

[0030] (3) Add porous ceramsite smaller than the volume of the solution into the aqueous solution, continue to stir for 5 minutes, then remove the impregnated ceramsite, and quickly air-cool until the agar is solidified into a gel, and peel off the excess surface of the agar. Agar gel, which is to obtain porous cerams...

Embodiment 2

[0032] Conductive lightweight porous ceramsite loaded with modified agar is prepared by immersing thermally modified agar aqueous solution, and cement-based material products for conductivity or antistatic are prepared by this method:

[0033] (1) According to the mass ratio of 100:6:0.5:3, weigh water and NaNO 2 , NaOH and agar powder;

[0034](2) Add the agar powder into the water first, keep stirring and heat until boiling until the agar is completely dissolved, then add NaOH, NaNO 2 Add the weighed modified electrolyte in the following order, keep the solution temperature above 90°C and keep stirring for 30s to prepare the modified agar aqueous solution;

[0035] (3) Add porous ceramsite smaller than the volume of the solution into the aqueous solution, continue to stir for 5 minutes, then remove the impregnated ceramsite, and quickly air-cool until the agar is solidified into a gel, and peel off the excess surface of the agar. Agar gel, which is to obtain porous ceramsi...

Embodiment 3

[0037] The above-mentioned conductive particles are used as lightweight aggregates for the preparation of cement mortar, and the mortar ratio is as follows:

[0038] Table 1

[0039] Example Cement (PII 42.5R) (g) Composite ceramsite (g) water (g) 1 540 430 238 2 540 550 238

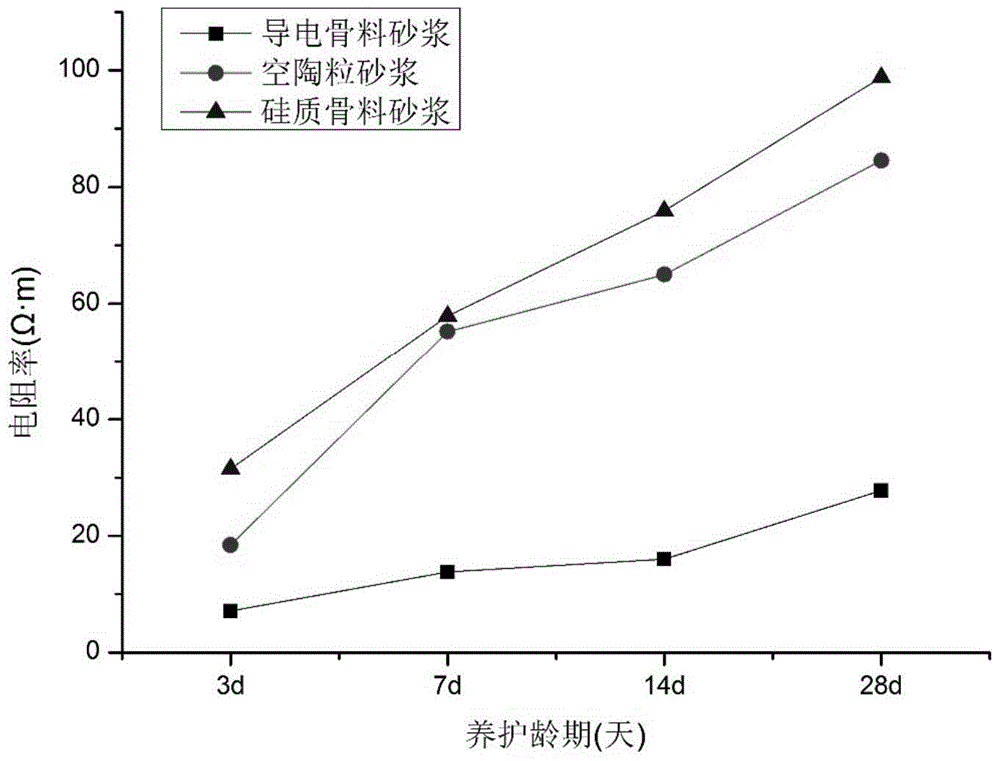

[0040] The mortar prepared according to the ratio of No. 1 in the above table is formed into image 3 After the 40*40*160mm mortar size specimen is in good condition, the four-point test method is adopted within a certain age period, and the resistivity data is tested by applying a 3V DC power supply, and the calculated figure 2 Trend chart of resistivity change. The siliceous aggregate group in the figure is the trend diagram of resistivity change of standard mortar produced by the national standard method, and the empty ceramsite group is the trend diagram of resistivity change of mortar made of the same blank ceramsite. It can be seen from the information in the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com