Coal-water slurry and preparation method thereof

A coal-water slurry and slurry technology, which is used in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of inability to prepare high-concentration coal-water slurry, and achieve the effects of reducing voids, increasing bulk density, and increasing concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

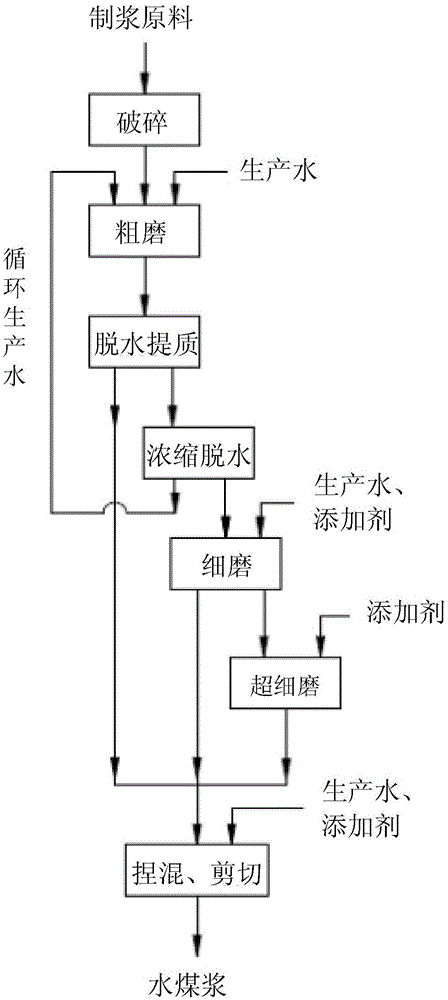

[0068] In the present embodiment, the coal-water slurry is prepared from lignite, and the lignite used is Dongming Coal Mine lignite in Hailaer, Inner Mongolia. In this coal, the analysis water is 21.8%, the total water is 34.5%, the ash is 8.5%, and the particle size is less than 50mm. The technological process of the method for preparing coal-water slurry is as figure 1 As shown, it specifically includes the following steps:

[0069] (1) Crush the raw material to a particle size of ≤13mm, then mix it with production water at a mass ratio of 4:6, and then conduct coarse grinding at a temperature of 30°C to obtain the first slurry, in which the particle size of coal particles in the first slurry is ≤ 2.4mm, and the particle size of 33% of the coal particles in the first slurry is less than or equal to 75μm;

[0070] (2) The first slurry is dehydrated and upgraded. The material with a solid content of 70% is used as slurry A, and the material with a solid content of 12.5% is...

Embodiment 2

[0076] In the present embodiment, the coal-water slurry is prepared from the long-flame coal in the Ili area of Xinjiang. The analyzed water in the coal is 12.7%, the total water is 21.9%, the ash content is 10.4%, and the particle size is less than 50mm; the preparation of the coal-water slurry The method specifically includes the following steps:

[0077] (1) Crush the raw material to a particle size ≤ 13mm, then mix it with production water at a mass ratio of 5:5, and then carry out coarse grinding at a temperature of 50°C to obtain the first slurry, in which the coal particles are diameter≤2.4mm, and the particle diameter of 35% of the coal particles in the first slurry is less than or equal to 75μm;

[0078] (2) The first slurry is dehydrated and upgraded. The material with a solid content of 75% is used as slurry A, and the material with a solid content of 10% is used as the second slurry. The particle size of the coal particles in the slurry A is ≤2.4mm, and the part...

Embodiment 3

[0084] In this embodiment, the coal-water slurry is prepared from the weakly caking coal in the Shenfu area of Ordos, Inner Mongolia. The analyzed water in the coal is 5.7%, the total water is 13.6%, the ash content is 6.9%, and the particle size is less than 50mm; the coal-water slurry The preparation method specifically comprises the following steps:

[0085] (1) Crush the raw material to a particle size ≤ 13mm, then mix it with production water at a mass ratio of 6:4, and then carry out coarse grinding at a temperature of 25°C to obtain the first slurry. The coal particles in the first slurry are diameter≤2.4mm, and the particle diameter of 37% of the coal particles in the first slurry is less than or equal to 75μm;

[0086] (2) The first slurry is dehydrated and upgraded. The material with a solid content of 80% is used as slurry A, and the material with a solid content of 9% is used as the second slurry. The particle size of the coal particles in the slurry A is ≤2.4mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap