Automatic turning and unloading device

An automatic turning and power technology, applied in the directions of packaging, loading/unloading, transportation and packaging, etc., can solve the problems of incomplete unloading, low production efficiency, inconvenient collaborative operation, etc., and achieve the effect of complete unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

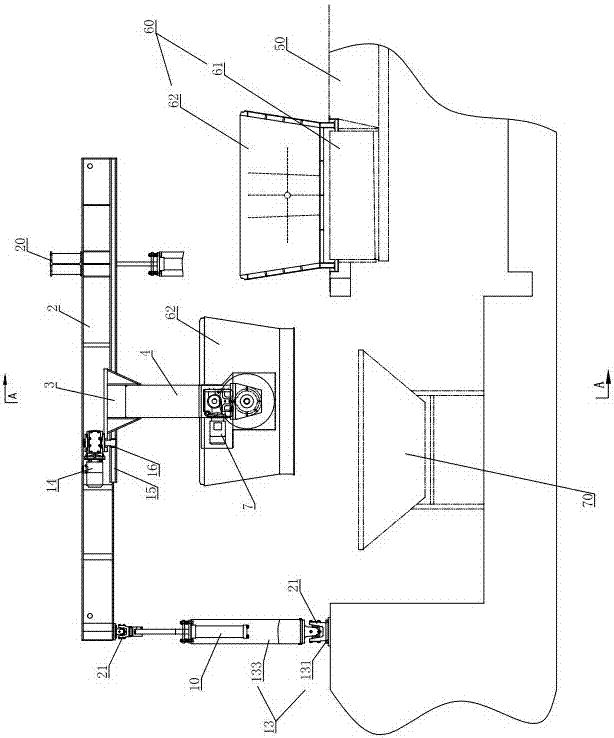

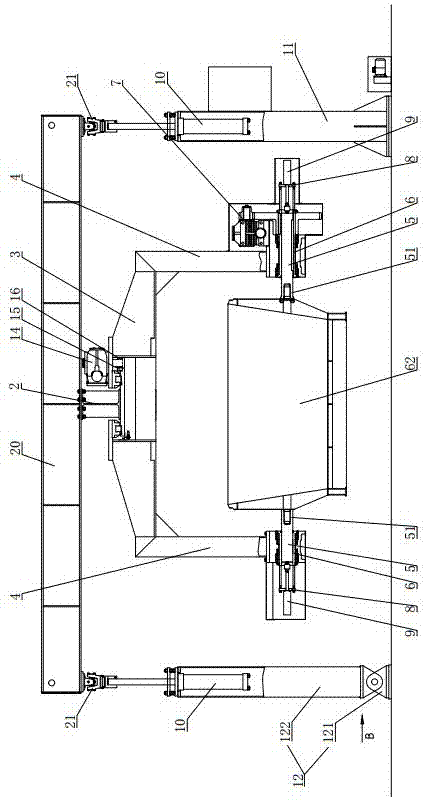

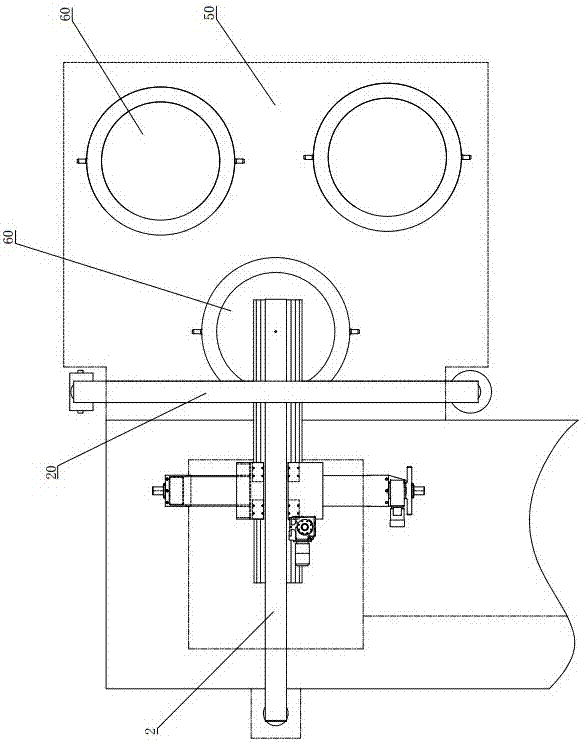

[0019] like figure 1 , figure 2 and image 3 As shown, the present invention provides an embodiment of an automatic turning over steamer unloading device, for convenience of description, with figure 1 The left and right direction in the figure is the longitudinal direction of the device. The device is installed on the brewing production line. The brewing production line is provided with a multi-station wine steaming device 50. The multi-station wine steaming device is provided with a plurality of rotatable distillation retorts 60. In order to carry out multi-station continuous distillation of wine, the distillation retort 60 is a two-body structure, and the distillation retort 60 includes a retort base 61 arranged on a multi-station wine distillation device and a retort 62 connected to the retort base. In the prior art, the retort barrel 62 is hoisted and transported to the retort hopper 70 behind the multi-station wine steaming device 50 by a crane. The entire unloading pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com