a cotton cleaning machine

A cotton cleaning machine and cotton cleaning technology, which is applied in the field of cotton cleaning machines, can solve the problems of low seed cotton impurity content, inability to distribute uniform work rolls, and difficulty in achieving the best cleaning effect, so as to improve the cleaning effect and cleaning effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

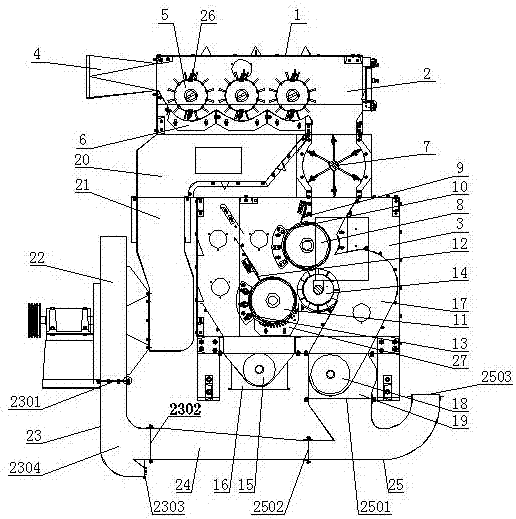

[0025] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0026] As shown in the figure, the present invention comprises frame and casing 1, is provided with upper chamber 2 and lower chamber 3 in casing 1, is provided with and communicates with upper chamber 2 on one side of casing 1 top. The feeding port 4 is provided with three nailing rollers 5 arranged side by side on the frame near the feeding port 4 in the upper chamber 2, and three nailing rollers 5 corresponding to the nailing rollers 5 are arranged below the nailing rollers 5. 1. Interconnected separation net bottoms 6, the separation net bottoms 6 have leakage holes, and the upper surface of each separation net bottom 6 is an arc surface matched with the scraper 26 of the spike roller 5. Each nailing roller 5 is provided with a scraper 26 matched with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com