Cloth cleaning brush roller of brushing machine

The technology of a brush roller and brushing machine is applied in the directions of mechanical cleaning, high-pressure cleaning, textiles and paper making, etc., and can solve the problems that the practicability needs to be improved, the cleaning effect and efficiency of the cloth cleaning brush roller are affected, and the binding force is weak. Cleaning effect and lasting, strong practicability, novel and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

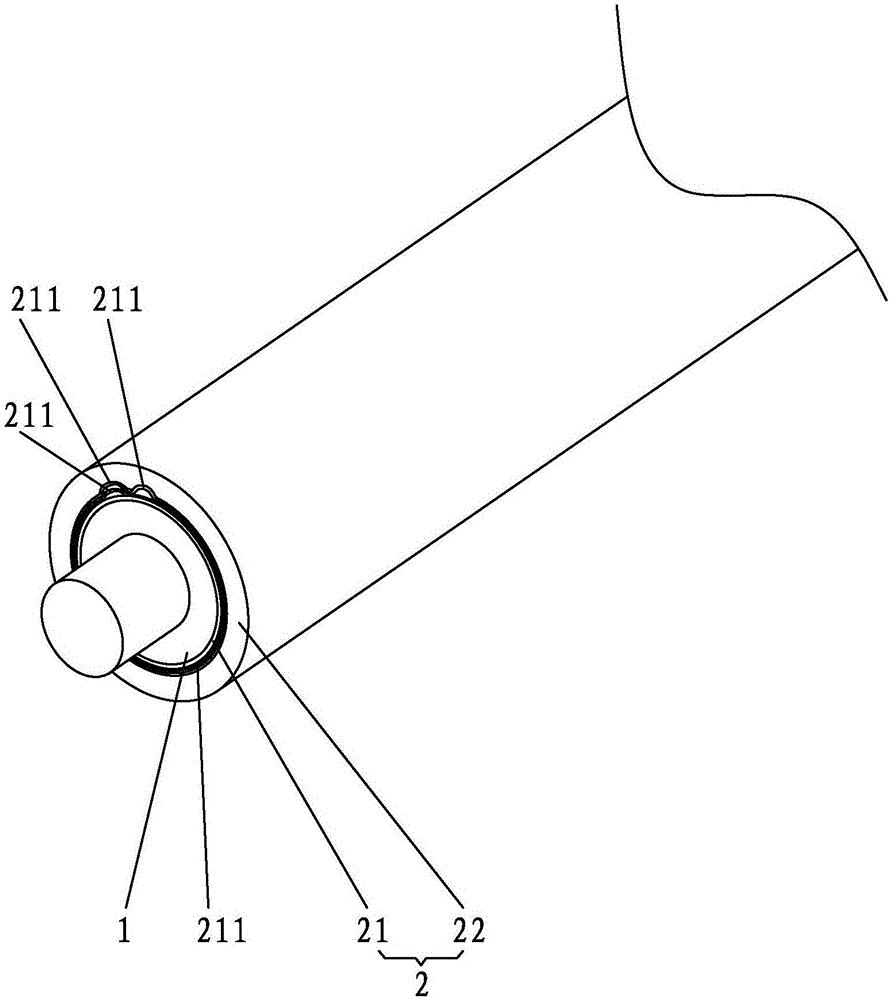

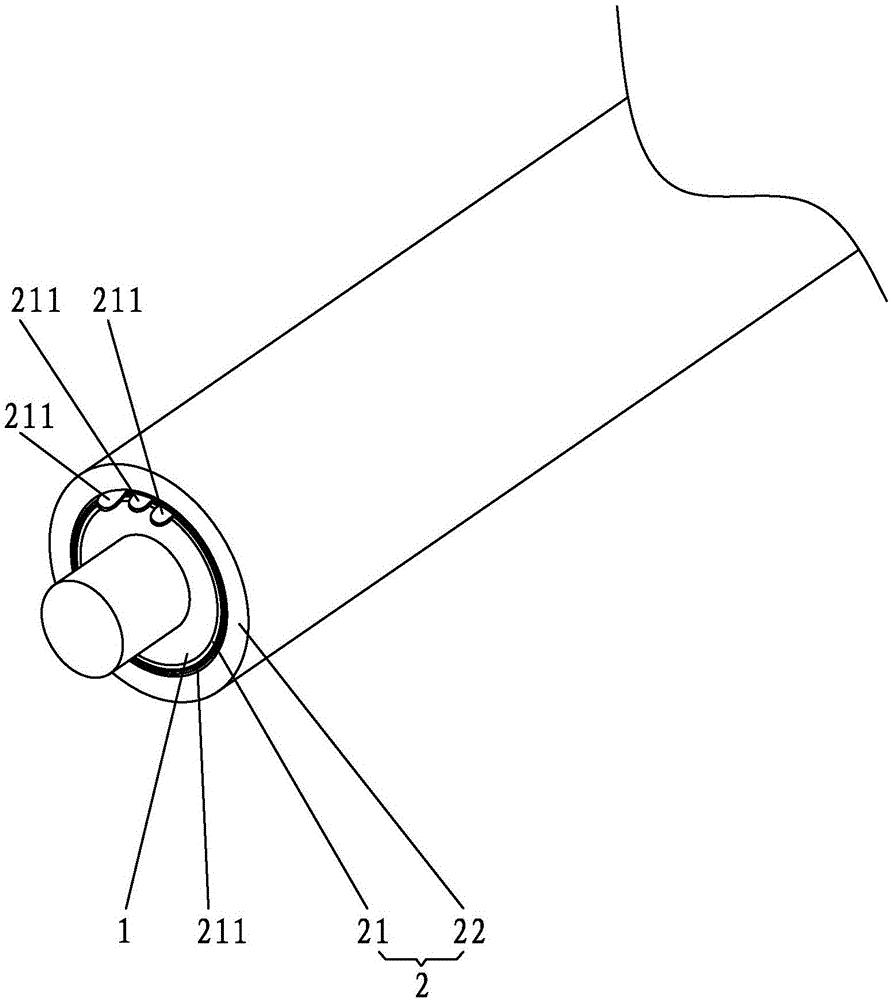

[0026] The cloth cleaning brush roller of brush hair machine of the present invention, as Figure 1-3 As shown, it includes a roller main body 1 and a flexible brush layer 2 wound on the peripheral surface of the roller main body 1 .

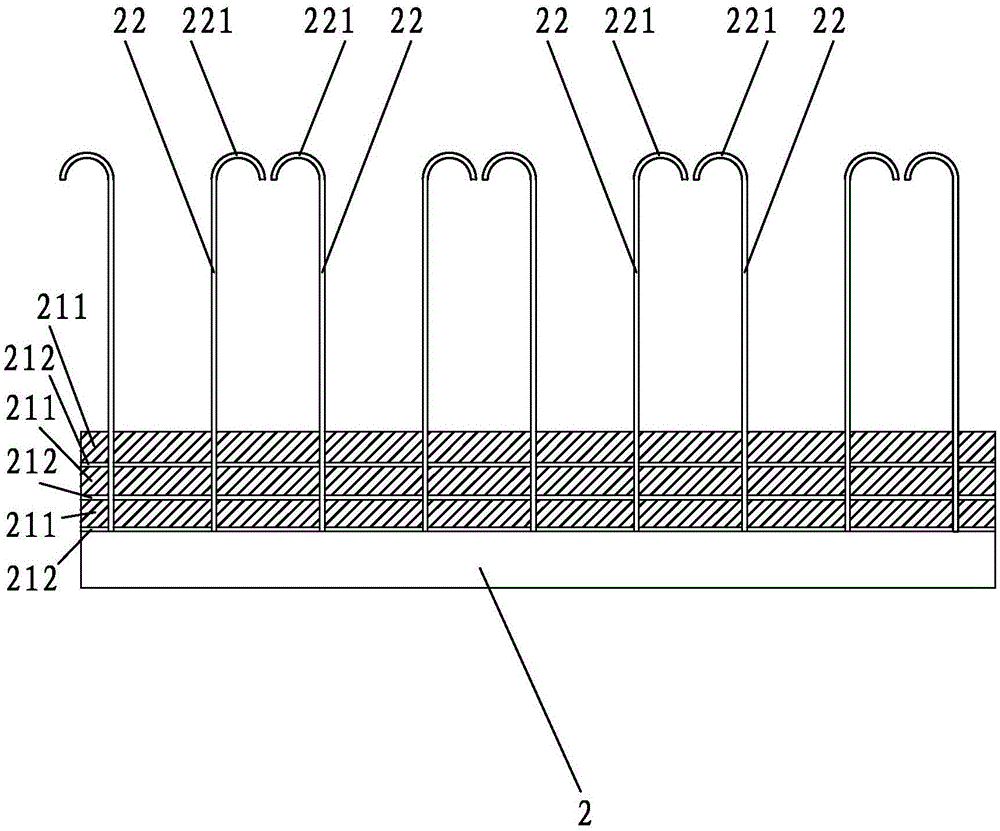

[0027] The flexible brush layer 2 includes a flexible bearing base layer 21, and a plurality of brush teeth 22 arranged on one side of the flexible bearing base layer 21; the flexible bearing base layer 21 has an inner surface combined with the roller main body 1, and an outer surface facing the outside, and the brush teeth 22 is formed on the outer surface of the flexible bearing base 21; the outer end of the brush teeth 22 is formed with a crotch 221; the outer surface of the flexible bearing base 21 is covered with at least one detachable layer 211, and the detachable layer 211 is formed with a Eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com