Flue gas pretreatment device blocking monitoring device and method

A monitoring device and flue gas technology, which is applied in the direction of optical device exploration, etc., can solve the problems of increasing instrument cost and consumption, difficulty of operation, filter blockage, inaccurate monitoring, etc., and achieve the effect of efficient monitoring of flue gas components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

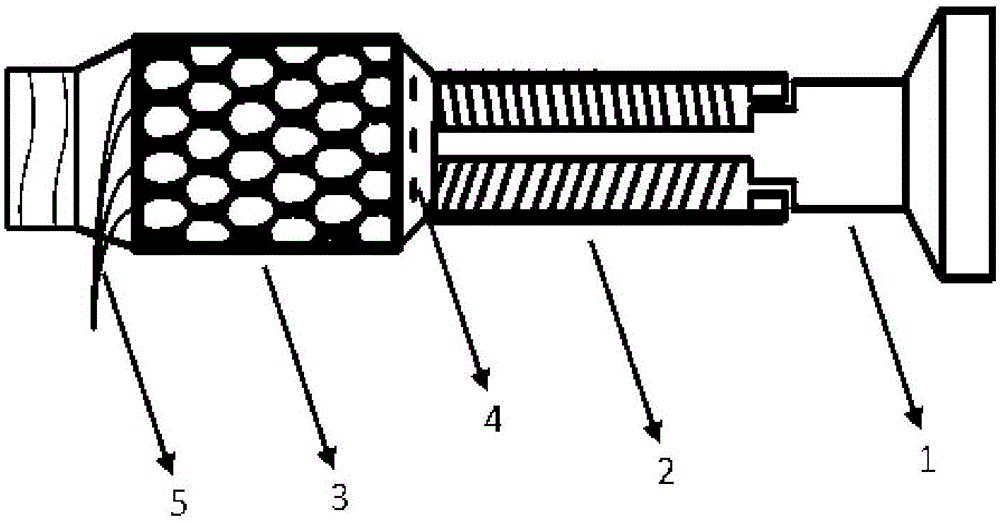

[0021] A flue gas pre-treatment device clogging monitoring device based on 1064nm laser energy measurement, the flue gas pre-treatment device includes a heating device and a sampling probe, the sampling probe is as figure 1 As shown, it includes a filter head 3, an air guide tube 2 and a connection port 1 connected in sequence. The filter head is provided with a multi-layer filter, and it is characterized in that a high-temperature-resistant collimating optical fiber 5 is provided in front of the filter head. The input end of the high-temperature-resistant collimating fiber is connected with a 1064nm frequency-stabilized laser; the rear of the filter head is provided with an evenly distributed miniature laser energy monitoring probe 4, and the output end of the evenly distributed miniature laser energy monitoring probe is connected with A control system, a control valve is connected to the control system, and the control valve controls the probe.

[0022] The evenly distribute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com