Mining area vehicle maintenance information prompting method

An information prompt, mining area technology, applied in the registration/indication of vehicle operation, registration/instruction, instruments, etc., can solve problems such as vehicle casualties, and achieve the effect of facilitating field operations, reducing vehicle failure rates, and improving vehicle attendance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

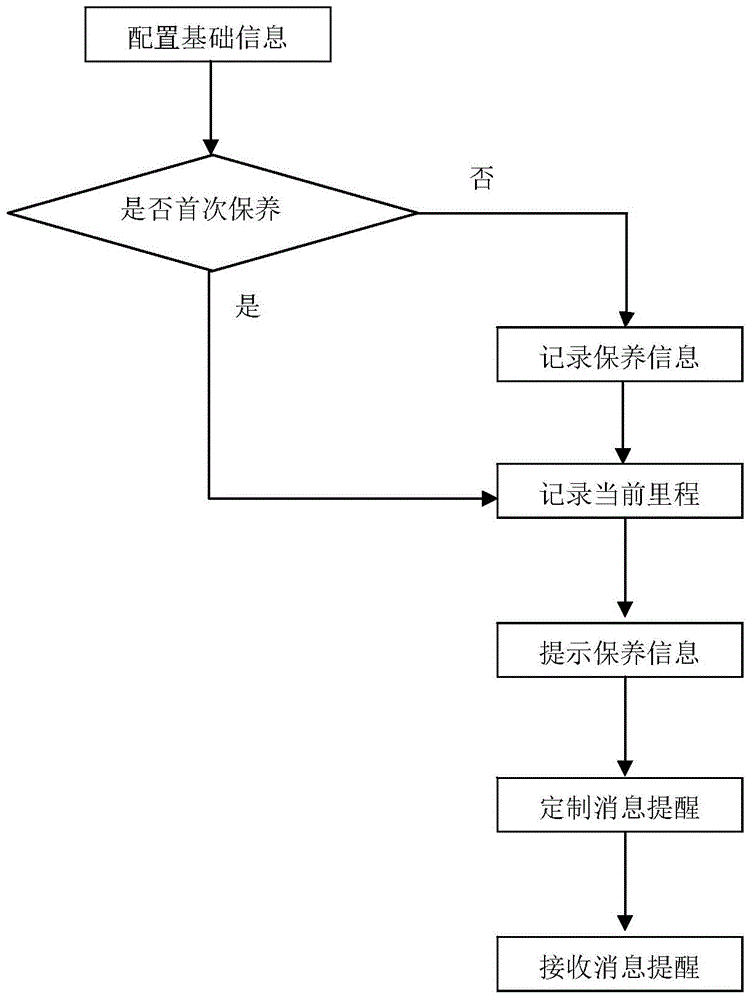

[0046] Example 1 1. One of the methods for prompting vehicle maintenance information in mining areas, follow the steps below:

[0047] Step 1: Configure basic information. Fill in the name of the mining area, vehicle number (E A12345), frame number, average daily mileage (80km), and maintenance cycle (3000km for the first time, 5000km regularly) in the template to complete the batch import.

[0048] Step 2: Record maintenance information. Assuming it is the first maintenance, the cumulative mileage at the last maintenance is 0 by default.

[0049] Step 3: Record the current mileage. Record the current mileage of the target vehicle (E A12345) of 2200km.

[0050] Step 4: Prompt maintenance information. Remaining kilometers=maintenance cycle+mileage during last maintenance-current mileage=3000+0–2200=800, remaining driving days=remaining mileage / daily average mileage=800 / 80=10, prompt "distance from first time There are 800 kilometers left for maintenance! About 10 days of...

Embodiment 2

[0053] Embodiment 2, The second method for prompting vehicle maintenance information in mining areas is to follow the steps below:

[0054] Step 1: Configure basic information. Fill in the name of the mining area, vehicle number (E A11111), frame number, average daily mileage, and maintenance cycle (3000km for the first time, 5000km regularly) in the template to complete the batch import.

[0055] Step 2: Record maintenance information. Assuming it is not the first maintenance, record the accumulative mileage of the target vehicle (E A11111) last maintenance is 2900km.

[0056] Step 3: Record the current mileage. Record the current mileage of the target vehicle is 7500km.

[0057] Step 4: Prompt maintenance information. Remaining kilometers=maintenance cycle+mileage during last maintenance-current driving mileage=5000+2900–7500=400, remaining driving days=remaining driving mileage / daily average driving There are 400 kilometers left for maintenance! About 5 days of drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com