Thin film transistor, fabrication method thereof, array substrate and display panel

A technology for thin film transistors and array substrates, applied in the field of semiconductor bodies, can solve the problems of performance deterioration of thin film transistors, no switching performance of oxide thin film transistors, destruction of metal oxide active layers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

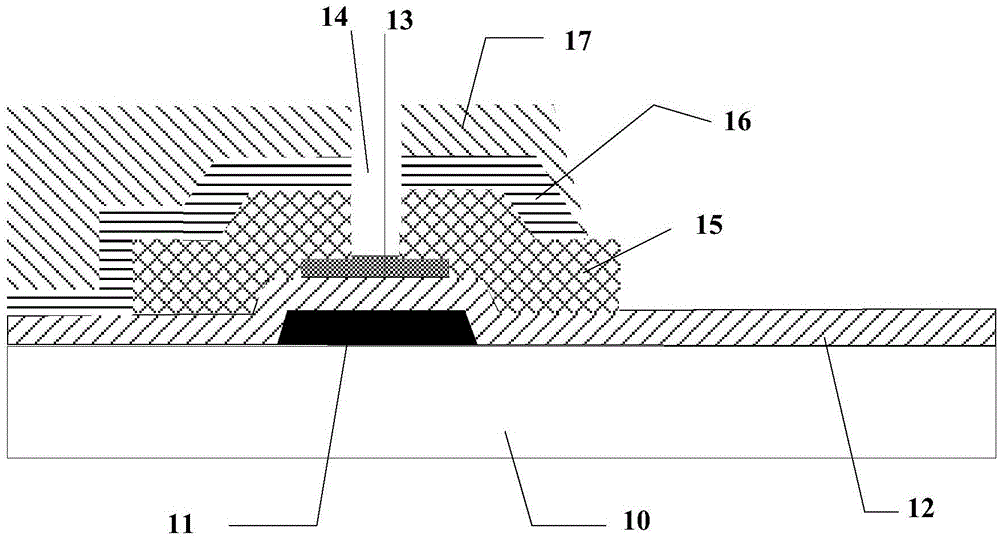

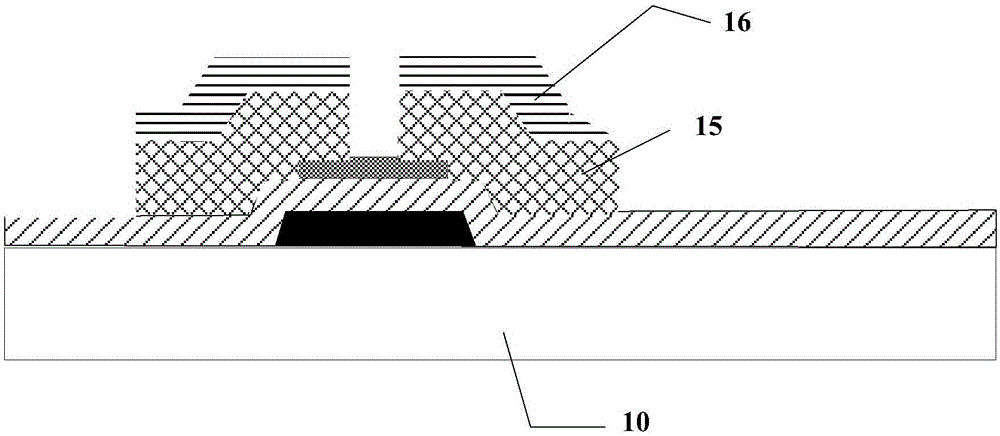

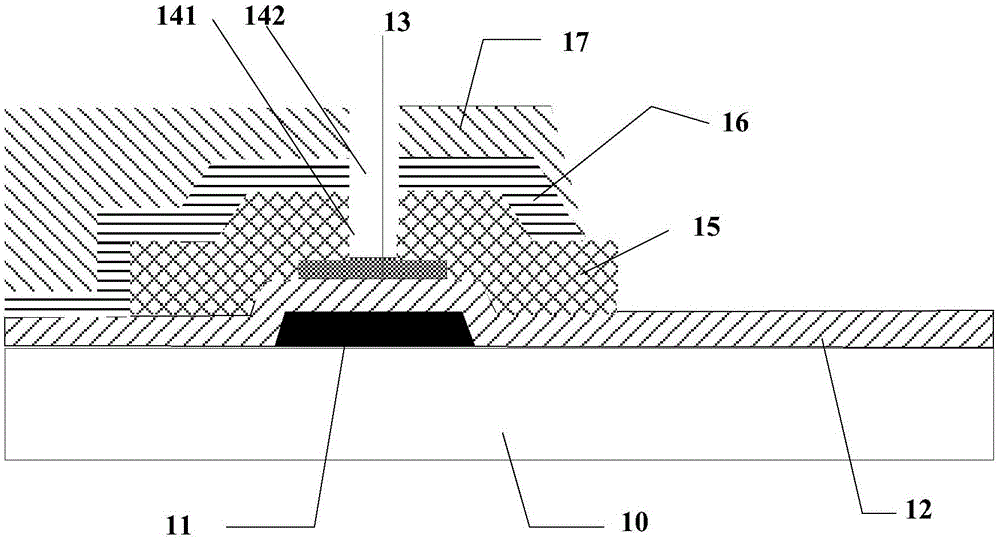

[0037] A thin film transistor provided by Embodiment 1 of the present invention, such as Figure 1a As shown, it includes: a base substrate 10, a gate electrode 11, a gate insulating layer 12, an active layer 13, and a source-drain electrode 15 located on the base substrate 10 in sequence; it also includes:

[0038] An oxidation protection layer 16 disposed on the source-drain electrodes 15 .

[0039] Through the opening 14 of the oxidation protection layer 16 , the opening 14 corresponds to the active layer region between the source and drain electrodes 15 .

[0040] In the thin film transistor provided by the embodiment of the present invention, an oxidation protection layer is provided on the source and drain electrodes, which avoids the problem that the source and drain electrodes are oxidized during the formation process and affects the performance of the thin film transistor. It is precisely because the oxide protection layer is provided on the source and drain electrode...

Embodiment 2

[0073] Based on the same inventive concept, Embodiment 2 of the present invention also provides a method for manufacturing a thin film transistor, which includes: sequentially forming the active layer of the thin film transistor, forming the thin film of the source and drain electrode layers of the thin film transistor, and forming the oxidation protection layer of the thin film transistor. layer film, forming the first opening of the channel region of the active layer corresponding to the source and drain electrode layer film, and forming the second opening of the channel region of the active layer corresponding to the oxidation protective layer film, wherein the first opening and the second The openings are formed by one patterning process. The specific process is as image 3 As shown, the following are detailed descriptions:

[0074] 301. Form a pattern of a gate electrode on a base substrate.

[0075] The base substrate can be a transparent glass substrate or quartz.

...

Embodiment approach

[0095] The first implementation mode: the active layer, the source and drain electrodes of the thin film transistor and the oxidation protection layer of the thin film transistor can be formed through one patterning process.

[0096] Specifically, such as Figure 4g As shown, the active layer 231 , the source and drain electrodes 241 of the thin film transistor and the oxidation protection layer 251 of the thin film transistor are formed by one patterning process.

[0097] Preferably, the active layer, the source and drain electrodes of the thin film transistor and the oxidation protection layer of the thin film transistor can be formed through a halftone mask or a gray scale mask.

[0098] The second implementation manner: before the step of forming the first opening, the method further includes: forming an active layer and a source-drain electrode layer film without the first opening through a patterning process. The resin layer of the thin film transistor, the oxidation pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com