Composite transparent conductive oxide film and preparation method thereof

An oxide thin film, transparent and conductive technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of single functionalization, can not meet the requirements of diversified performance of solar front electrode coatings, etc., achieve high chemical stability, Stable physical properties and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

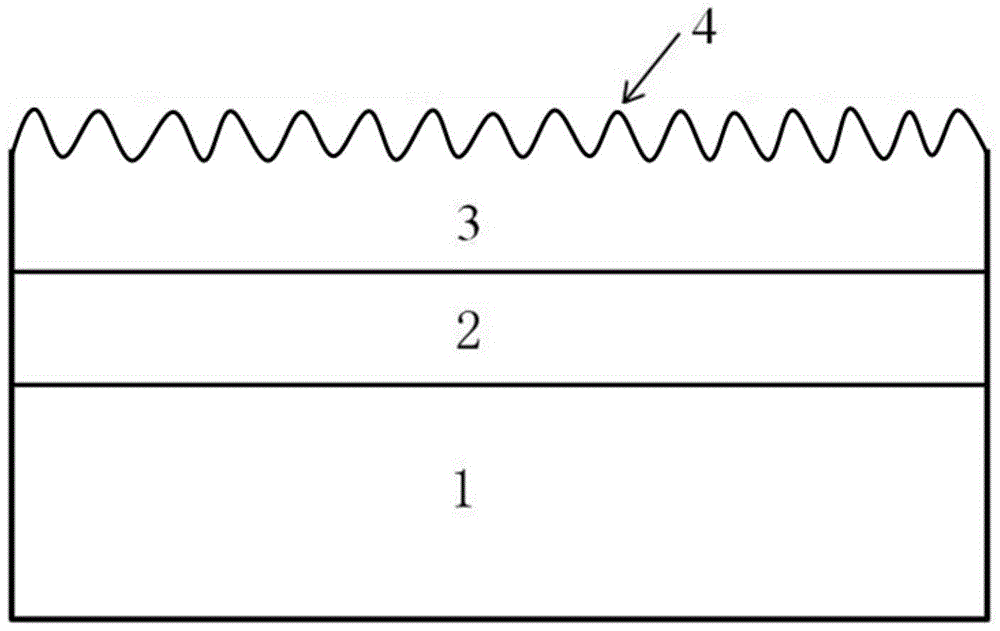

[0048] A composite transparent conductive oxide film of the present invention, such as figure 1 As shown, it is set on the substrate 1, the film includes an ITO layer 2 and a ZIO layer 3, the ITO layer 2 is set on the substrate 1, the ZIO layer 3 is set on the ITO layer 2, and the surface structure of the ZIO layer 3 is a suede structure.

[0049] A method for preparing the composite transparent conductive oxide film of the above-mentioned present embodiment, comprising the following steps:

[0050] (1) Preparation of ITO precursor solution: 29.05g indium chloride, 3.23g tin chloride, 1.98g methyl cellulose, 0.63g polyether organosiloxane leveling agent (FL-3), 2.34g poly After vinylpyrrolidone PVP was dissolved in 70mL of water by mechanical dispersion, it was dispersed for 10min under ultrasonic with a working frequency of 20KHz, and then stirred for 10min by a shear emulsification mixer with a speed of 6000r / min to obtain an ITO precursor solution with a pH of 7.3.

[0051...

Embodiment 2

[0058] A composite transparent conductive oxide film of the present invention, such as figure 1 As shown, it is set on the substrate 1, the film includes an ITO layer 2 and a ZIO layer 3, the ITO layer 2 is set on the substrate 1, the ZIO layer 3 is set on the ITO layer 2, and the surface structure of the ZIO layer 3 is a suede structure.

[0059] A method for preparing the composite transparent conductive oxide film of the above-mentioned present embodiment, comprising the following steps:

[0060] (1) Preparation of ITO precursor solution: 37.13g of indium nitrate, 3.62g of tin nitrate, 1.03g of carboxymethyl cellulose, 1.27g of sodium polyacrylate, and 0.68g of hexadecyltrimethylammonium bromide were dissolved in After 60mL of water, disperse for 7min under ultrasonic with a working frequency of 30KHz, and then stir for 8min with a shear emulsification mixer with a rotating speed of 5000r / min to obtain an ITO precursor solution with a pH value of 7.0.

[0061] (2) Preparat...

Embodiment 3

[0068] A composite transparent conductive oxide film of the present invention, such as figure 1 As shown, it is set on the substrate 1, the film includes an ITO layer 2 and a ZIO layer 3, the ITO layer 2 is set on the substrate 1, the ZIO layer 3 is set on the ITO layer 2, and the surface structure of the ZIO layer 3 is a suede structure.

[0069] A method for preparing the composite transparent conductive oxide film of the above-mentioned present embodiment, comprising the following steps:

[0070] (1) Preparation of ITO precursor solution: 43.2g indium nitrate, 4.64 tin chloride, 1.8g carboxypropyl methylcellulose, 1.8g polyacrylamide, 1.8g polyethylene glycol 1000 were dissolved in 70mL by mechanical dispersion After dispersing for 10 minutes under ultrasonic with a working frequency of 20KHz, and then stirring for 20 minutes by a shear emulsification mixer with a rotating speed of 4000r / min, an ITO precursor solution with a pH value of 7.2 was obtained.

[0071] (2) Prepara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com