Moving-coil loudspeaker

A moving coil loudspeaker and voice coil technology, applied in the direction of sensors, electrical components, etc., can solve the problems of the magnetic performance attenuation of the driving magnet, the reduction of the magnetic performance of the driving magnet, and the demagnetization, so as to reduce the degree of magnetic attenuation and reduce the effect of magnetic attenuation. , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

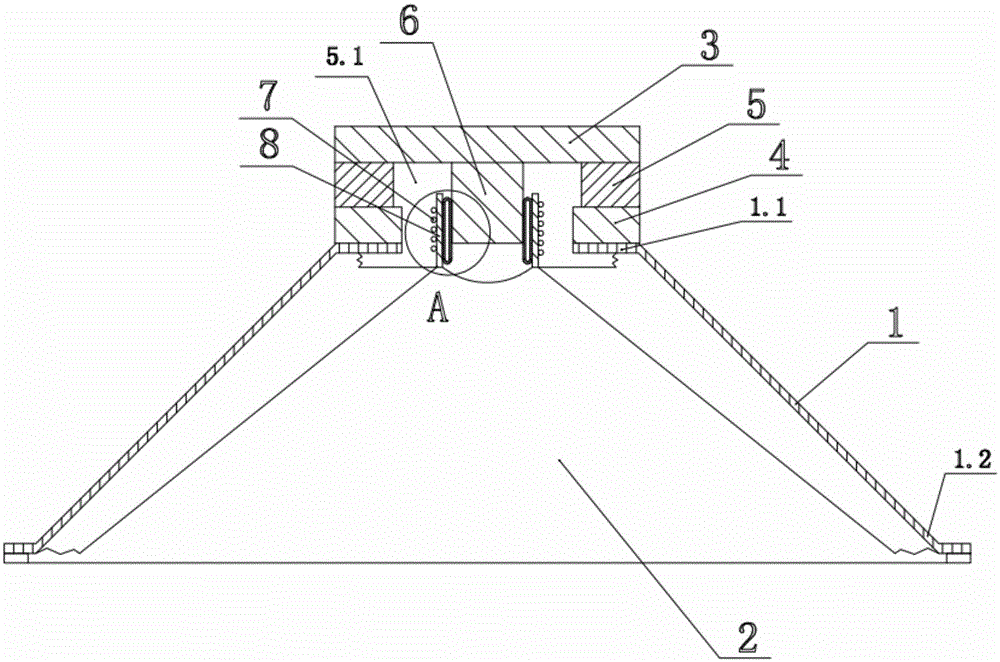

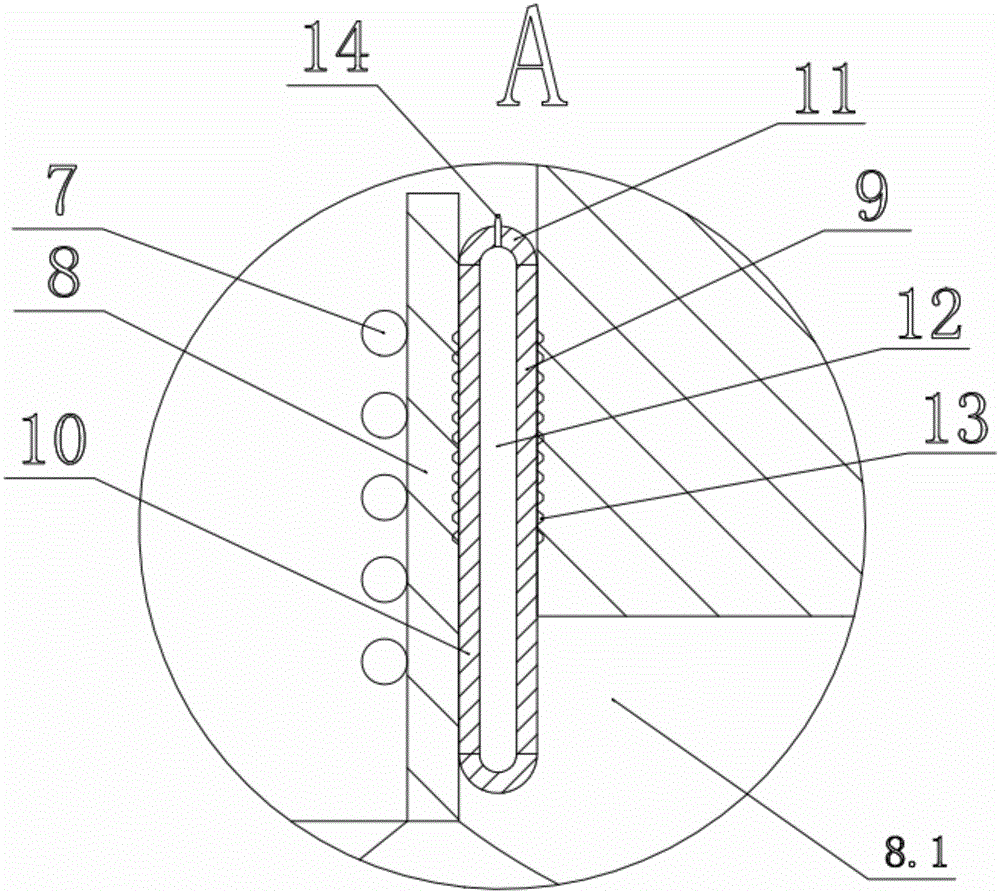

[0016] The present invention provides a moving coil loudspeaker, which includes a pot frame 1, a paper cone 2, a first magnetically conductive plate 3, a second magnetically conductive plate 4, a driving magnet 5, a magnetically conductive core post 6, a voice coil 7 and a voice coil Guide tube 8, the drive magnet 5 is clamped between the first magnetically conductive plate 3 and the second magnetically conductive plate 4, the second magnetically conductive plate 4 is fixed to the small mouth end 1.1 of the frame 1, and the voice coil 7 is wound on The outside of the voice coil guide cylinder 8, together with the voice coil guide cylinder 8, is accommodated in the center hole 5.1 of the driving magnet 5, one end of the voice coil guide cylinder 8 is fixed to one end of the paper cone 2, and the paper cone 2 is erected on the basin frame 1 , and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap