Tobacco seedling transplantation and fertilization integrated machine

An all-in-one machine and tobacco seedling technology, which is applied in transplanting machinery, fertilization devices, fertilizer distributors, etc., can solve the problems of tobacco seedling transplanting that cannot be mechanized, labor-intensive, and mechanized farming restrictions, etc. To achieve the effect of saving planting costs, reducing labor intensity and improving operational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The description of the exemplary embodiments is for the purpose of illustration only, and in no way limits the invention and its application or usage.

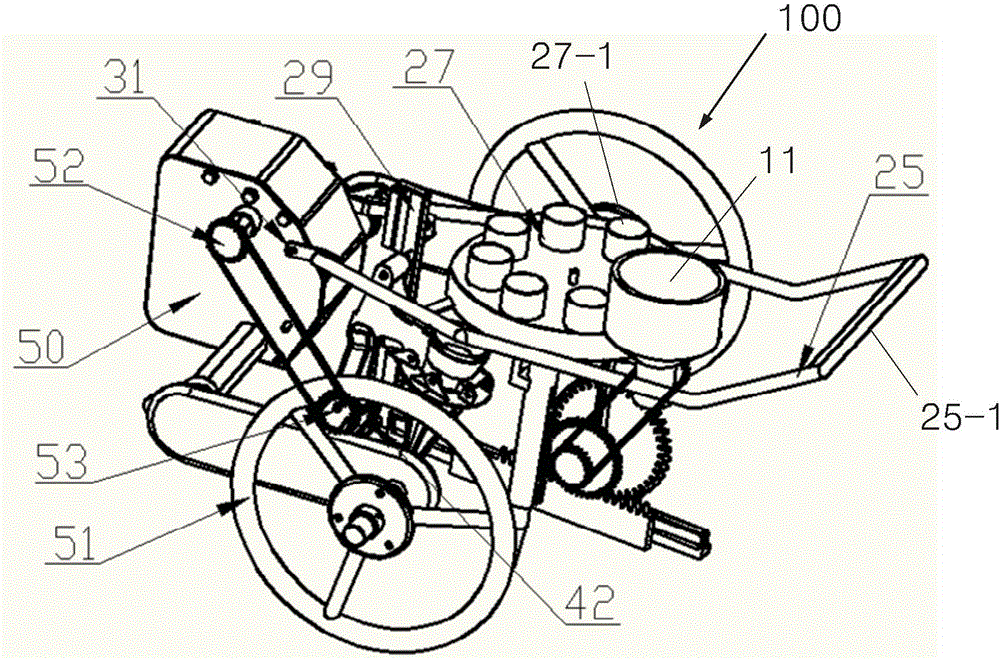

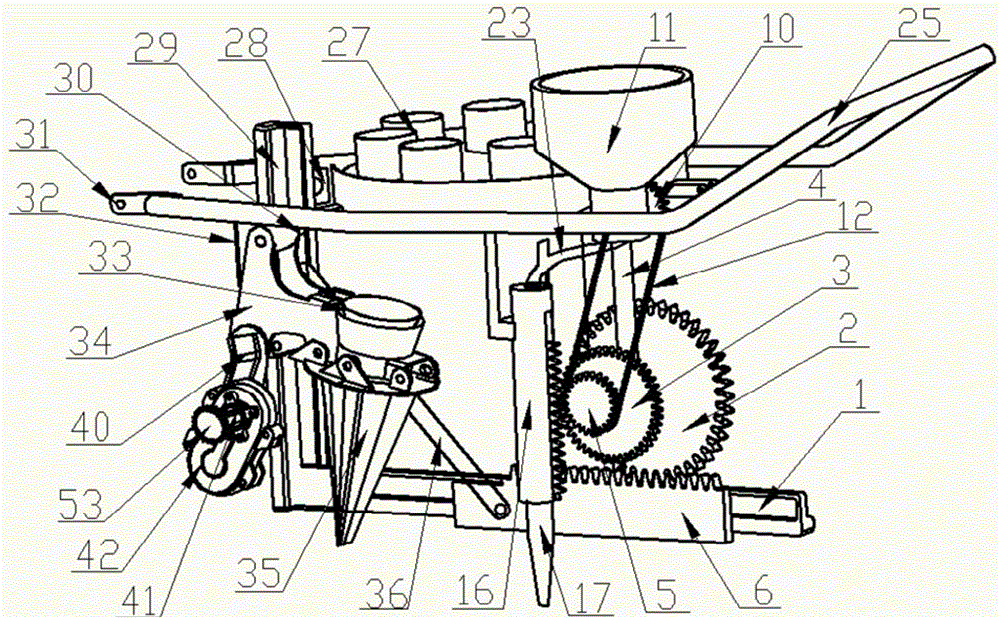

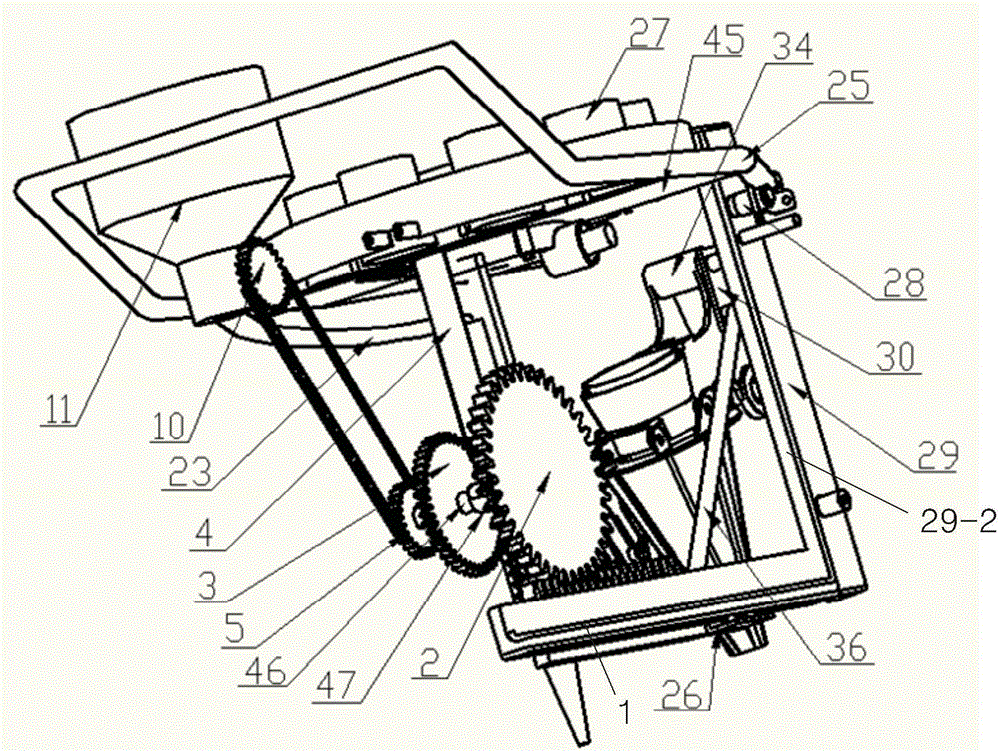

[0029] Such as figure 1 As shown, it shows a perspective view from the side of the tobacco seedling transplanting and fertilizing integrated machine 100 according to the present invention. The tobacco seedling transplanting and fertilizing integrated machine 100 according to the present invention comprises a frame part, a fertilizing part arranged on the frame part, a transplanting part arranged in front of the fertilizing part on the frame part, and a transplanting part and a fertilizing part The power transmission section that provides power. The various components of the integrated tobacco seedling transplanting and fertilizing machine 100 according to the present invention will be described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com