Leaf picking machine for corn plants

A leaf picker and plant technology, which is applied in the field of corn plant leaf pickers, can solve the problems of field canopy, increased incidence of diseases and insect pests, poor ventilation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

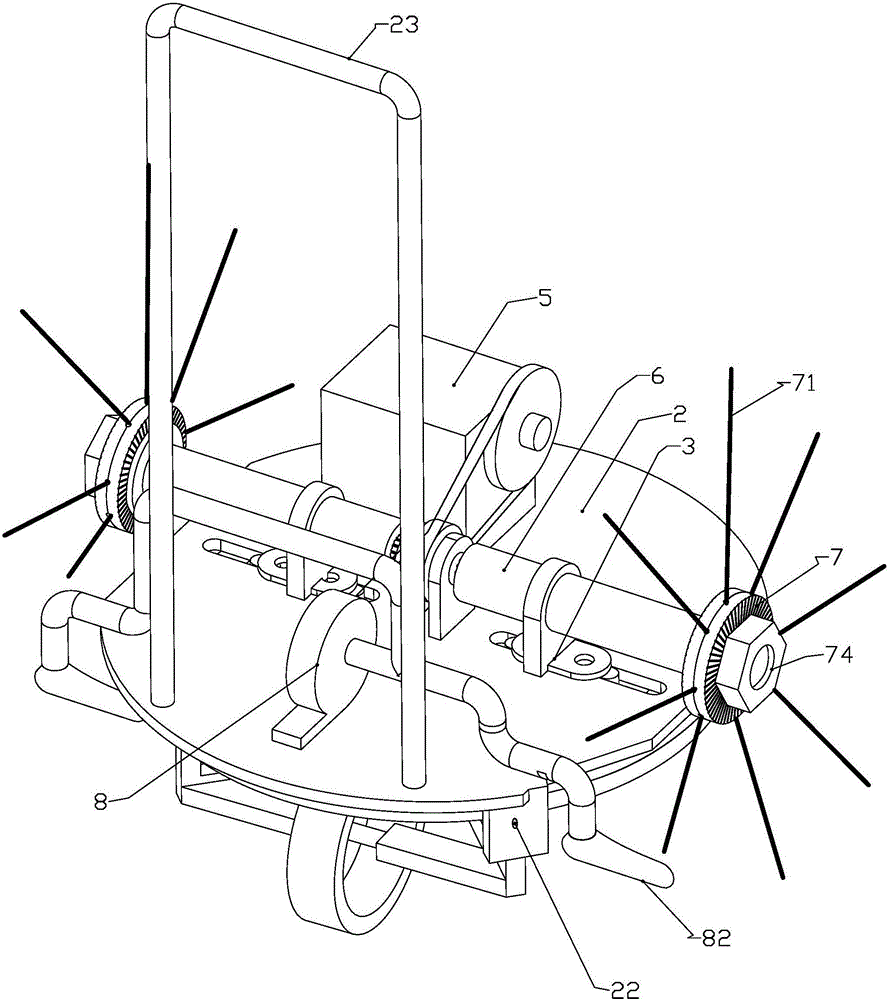

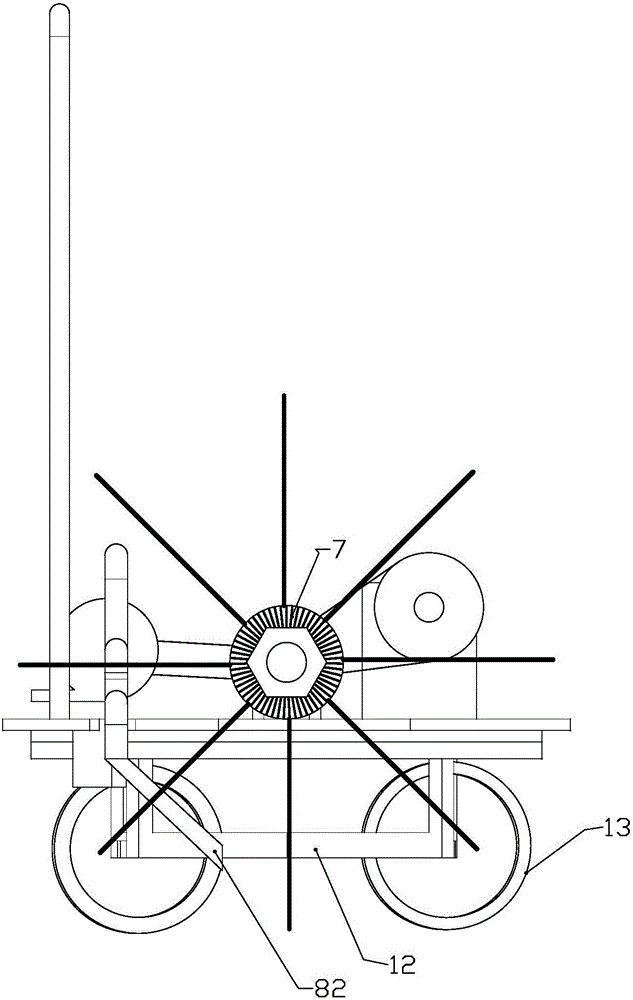

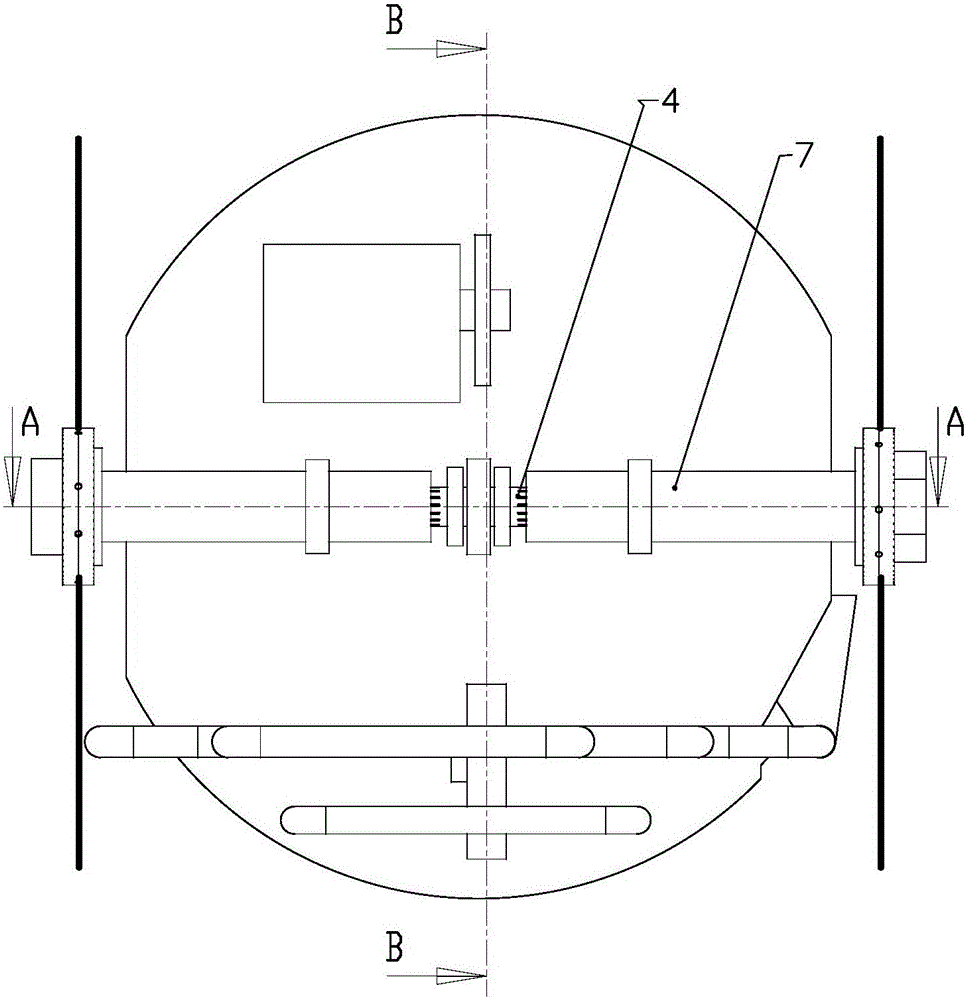

[0033] like Figure 1 to Figure 11 As shown, in view of existing defects, the subject of protection of this patent is as follows:

[0034] What was developed was a corn plant leaf picker, a machine that removes 3-4 leaves from the ground above the corn plant.

[0035] The basic principle is that it has the function of walking between rows of corn, and removes corn below a certain height during the walking process. The removal operation is carried out in a continuous and flexible tearing manner.

[0036] Based on the above description, it is first necessary to remove the three corn leaves at the lower part of the corn plant without affecting the upper corn leaves, and recycle the removed corn leaves. In terms of power, diesel engines are given priority for driving. It also has the function of assisting power for walking. According to the difference in plant row spacing and the difference in leaf height between different varieties, it must also have the function of adjusting b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com