A low-temperature desolventization process for soybean meal

A low-temperature desolvation and soybean meal technology, which is applied to the protein composition of vegetable seeds, food science, protein food composition, etc., can solve the problems of increasing operating costs and production costs, difficult concentration gradient of solvent vapor, and reducing soluble protein content, etc. Achieve the effect of being conducive to heat preservation, short heating time and low moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

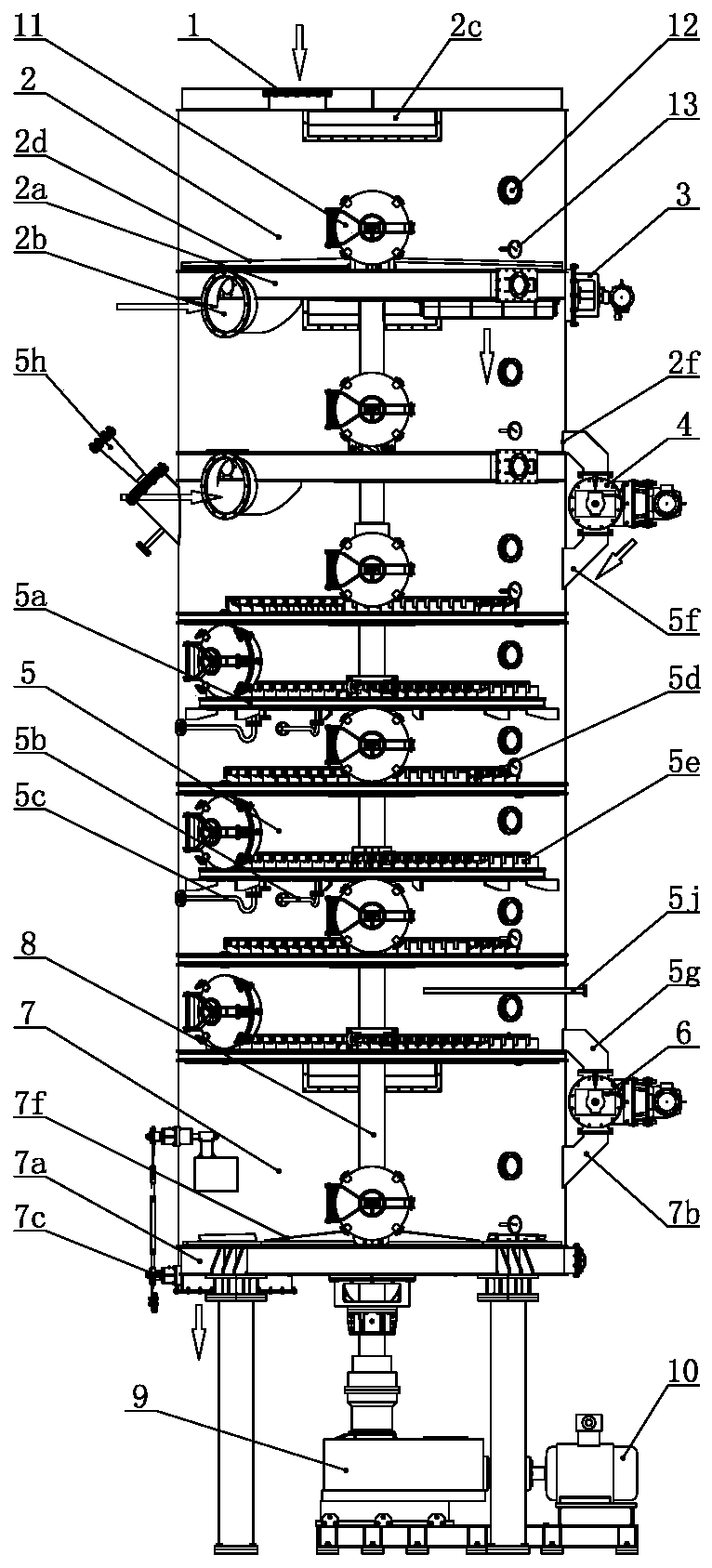

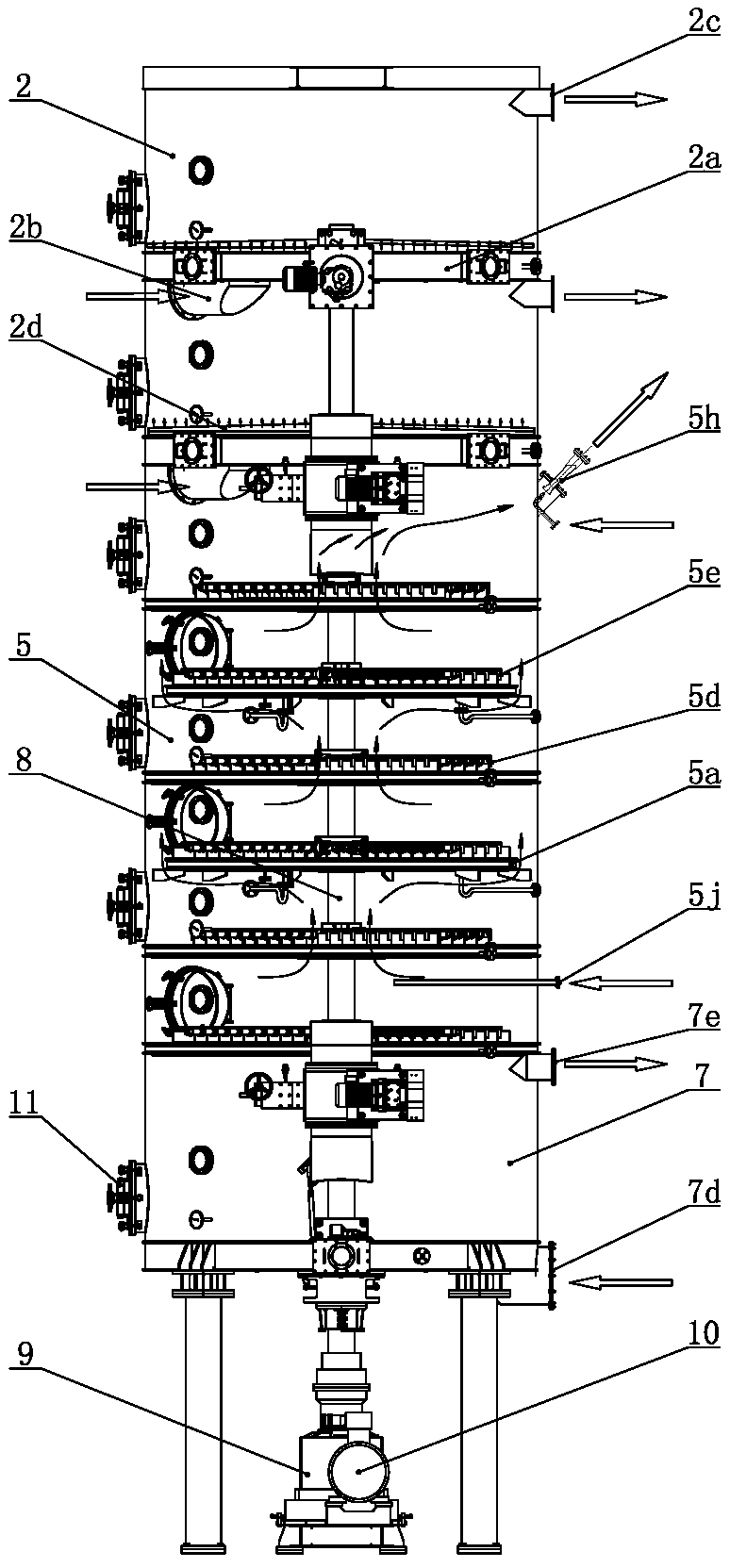

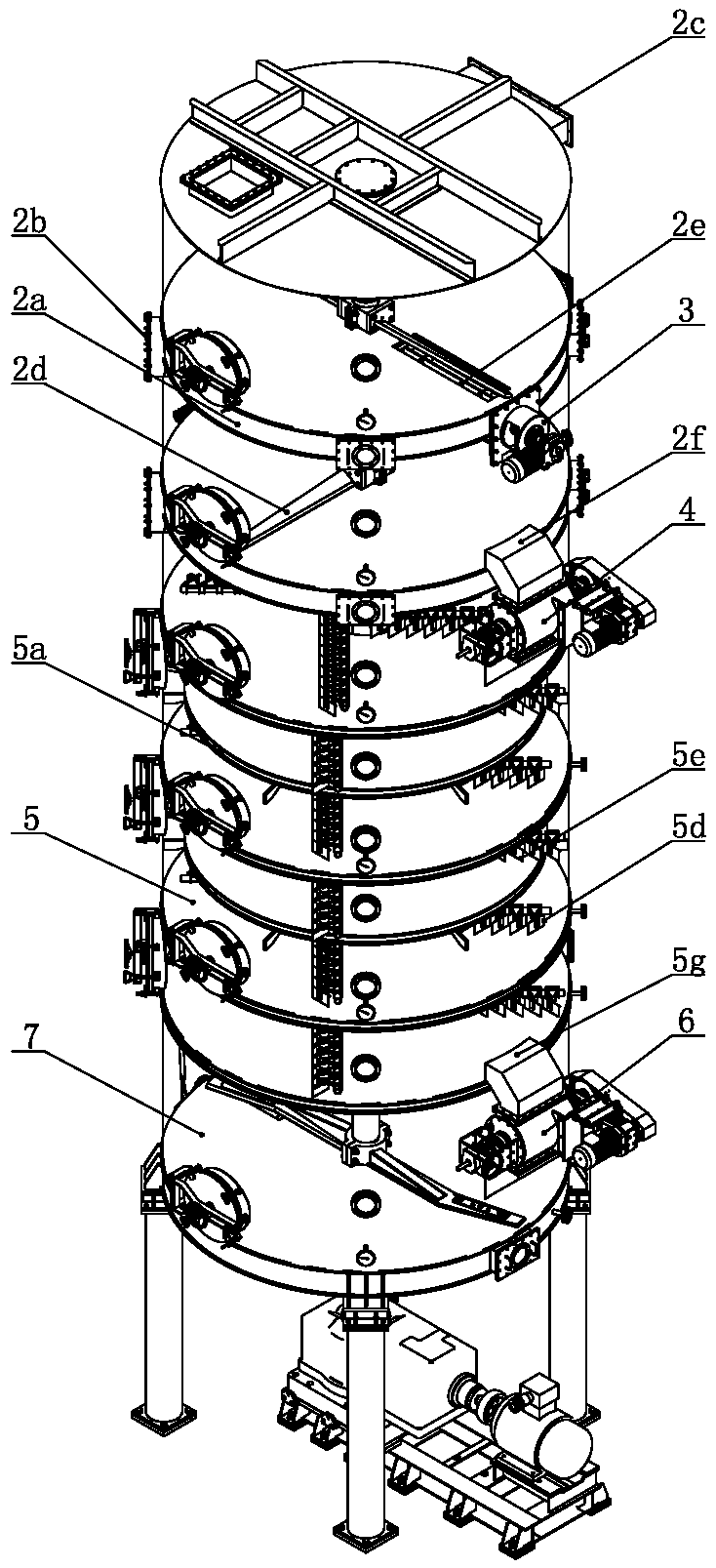

[0030] Such as Figure 2 to Figure 5 As shown, the flash vacuum desolventizing machine of the present invention includes a vertical cylinder, the top of the cylinder is provided with a total feed inlet 1, and the inner cavity of the cylinder is sequentially provided with a flash desolventizing section and a vacuum from top to bottom. Desolubilization section and dry cooling layer 7; Flash desolubilization section uses superheated solvent vapor to flash the wet meal.

[0031] The high-solubility wet meal enters the inner cavity of the cylinder from the total feed port 1 at the top of the cylinder, and first passes through the flash desolventizing section. In the flash desolventizing section, superheated solvent vapor is used as the desolventizing heat and mass transfer carrier to flash the wet meal. Desolubilization makes the high-moisture soluble meal become a low-content soluble meal, and then the low-content soluble meal becomes a medium temperature meal. The medium temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com