Common cutting technology for spud leg main cord rack plates of self-elevating drilling platform

A technology of drilling platform legs and cutting technology, applied in welding equipment, gas flame welding equipment, metal processing equipment and other directions, can solve the problems of large amount of waste, many cutting processes, waste of raw materials, etc., to improve the utilization rate and reduce Energy consumption and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

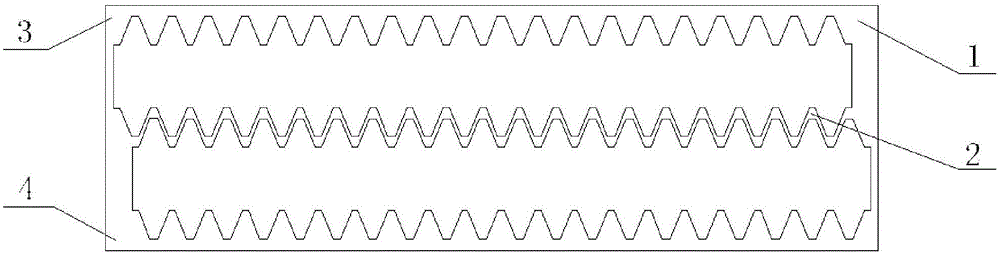

[0019] Using the co-edge cutting technology of the jack-up drilling platform pile leg main chord rack rack plate of the present invention, two toothed plates are simultaneously lowered from the steel plate with a thickness of 120mm:

[0020] 1) Preparation

[0021] Place the steel plate 1 to be cut on the cutting tire frame and fix the position; use computer drawing technology to determine the co-edge cutting tooth profile curve and seam width, and make a cutting model; determine the appropriate cutting tip and corresponding cutting edge according to the computer drawing results Cutting speed, cutting air pressure and other cutting parameters.

[0022] 2) Material preheating

[0023] Preheat the steel plate 1 placed on the tire frame, the preheating temperature is 150°C, to prevent the deformation of the rack plate due to uneven heat during the cutting process, and reduce the influence of the heat generated by cutting on the cutting accuracy.

[0024] 3) Tooth cutting

[00...

Embodiment 2

[0027] Using the co-edge cutting technology of the jack-up drilling platform pile leg main chord rack rack plate of the present invention, two toothed plates are simultaneously lowered from the steel plate with a thickness of 135mm:

[0028] 1) Preparation

[0029] Place the steel plate 1 to be cut on the cutting tire frame and fix the position; use computer drawing technology to determine the co-edge cutting tooth profile curve and seam width, and make a cutting model; determine the appropriate cutting tip and corresponding cutting edge according to the computer drawing results Cutting speed, cutting air pressure and other cutting parameters.

[0030] 2) Material preheating

[0031] Preheat the steel plate 1 placed on the tire frame, the preheating temperature is 200°C, prevent the deformation of the rack plate due to uneven heat during the cutting process, and reduce the impact of the heat generated by cutting on the cutting accuracy.

[0032] 3) Tooth cutting

[0033] Th...

Embodiment 3

[0035] Using the co-edge cutting technology of the jack-up drilling platform pile leg main chord rack rack plate of the present invention, two toothed plates are simultaneously lowered from the steel plate with a thickness of 150mm:

[0036] 1) Preparation

[0037] Place the steel plate 1 to be cut on the cutting tire frame and fix the position; use computer drawing technology to determine the co-edge cutting tooth profile curve and seam width, and make a cutting model; determine the appropriate cutting tip and corresponding cutting edge according to the computer drawing results Cutting speed, cutting air pressure and other cutting parameters.

[0038] 2) Material preheating

[0039] Preheat the steel plate 1 placed on the tire frame, the preheating temperature is 300°C, prevent the deformation of the rack plate due to uneven heat during the cutting process, and reduce the impact of the heat generated by cutting on the cutting accuracy.

[0040] 3) Tooth cutting

[0041] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com