Automatic screw locking machine

An automatic locking screw machine and screw technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of inclined inner side walls and stuck between the inner side walls of the suction end, sliding teeth, floating locks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

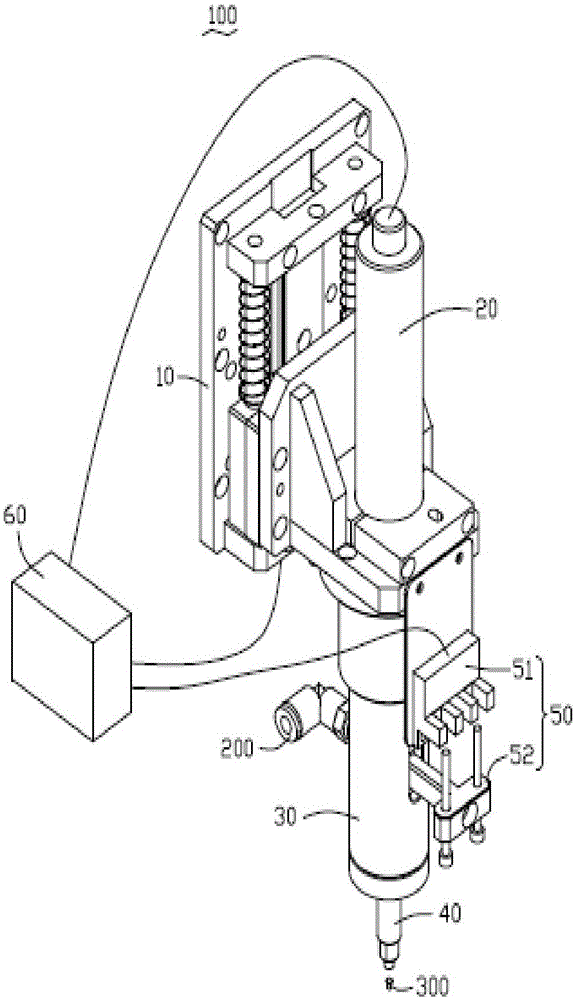

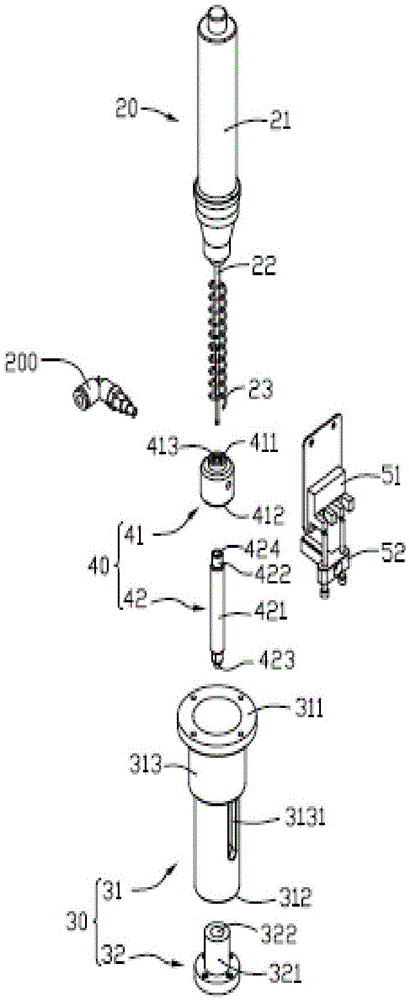

[0017] see figure 1 , an automatic locking screw machine 100, connected to a vacuum generator (not shown) through an air duct 200. Under the action of the vacuum generator, the automatic screw locking machine 100 generates an air pressure less than atmospheric pressure, thereby generating an adsorption force to absorb the screw 300 from the screw supply machine (not shown). Then, the automatic screw locking machine 100 locks the screw 300 on the product (not shown).

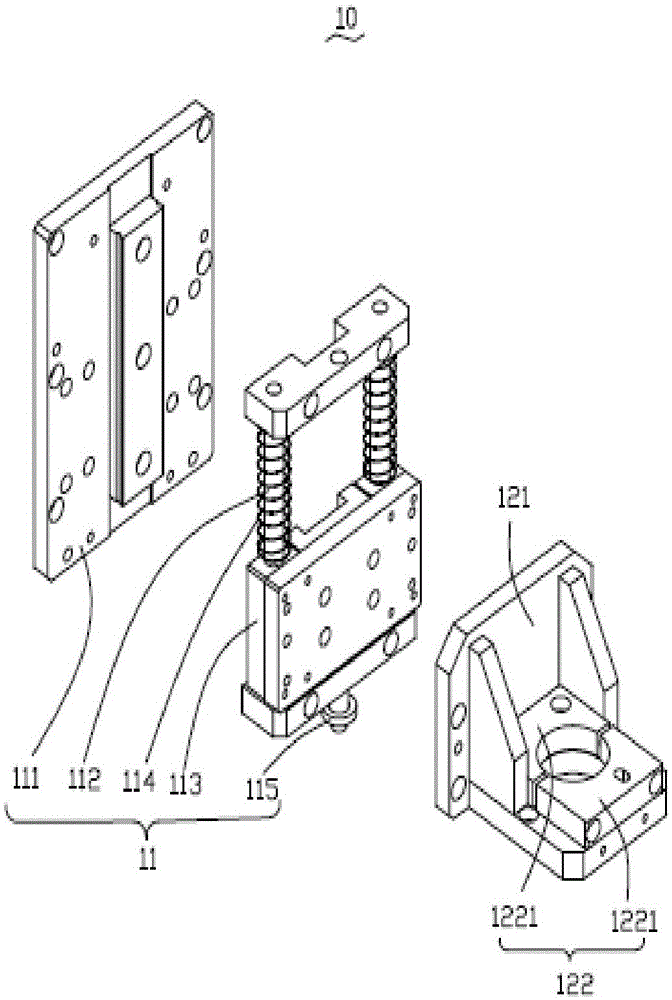

[0018] The automatic screw locking machine 100 includes a lifting assembly 10 , a locking assembly 20 , a guiding assembly 30 , an adsorption assembly 40 , a detection assembly 50 and a control module 60 . The locking assembly 20 , the guiding assembly 30 , the adsorption assembly 40 and the detection assembly 50 can be driven by the lifting assembly 10 to carry out lifting movement. The locking component 20 and the guiding component 30 can move relative to the adsorption component 40 under the action of extern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com