A kind of construction method of prefabricated structural column and prefabricated structural column reverse partition wall

A construction method and a technology of structural columns, which are applied in the direction of basic structure engineering, excavation, artificial islands, etc., can solve the problems of prefabricated parts tilting or offset, affecting the stability of supporting structure engineering, etc., to reduce the probability of offset and to operate easily , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The application will be described in further detail below in conjunction with the accompanying drawings and embodiments.

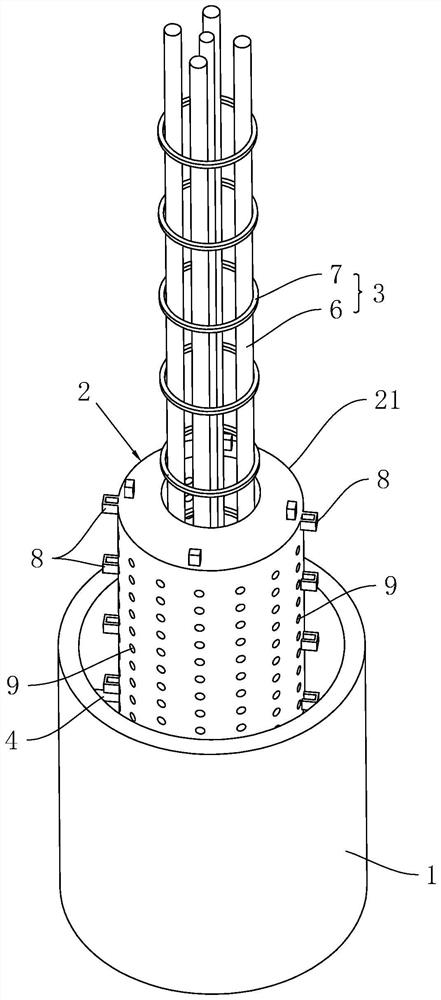

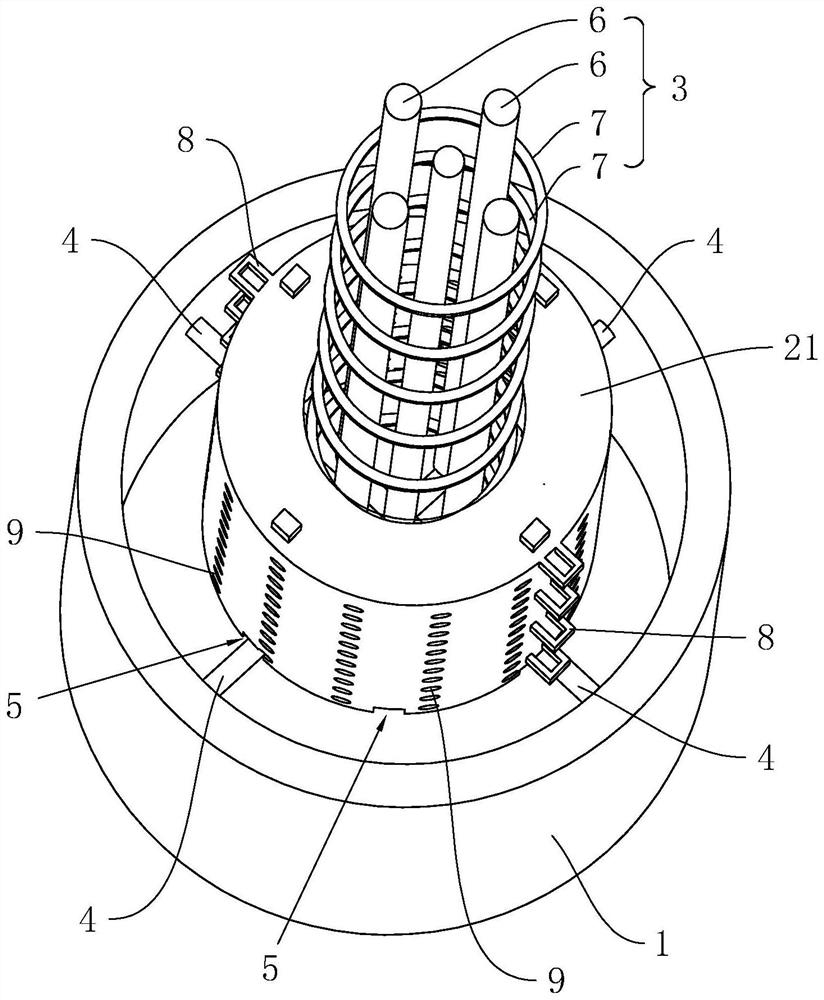

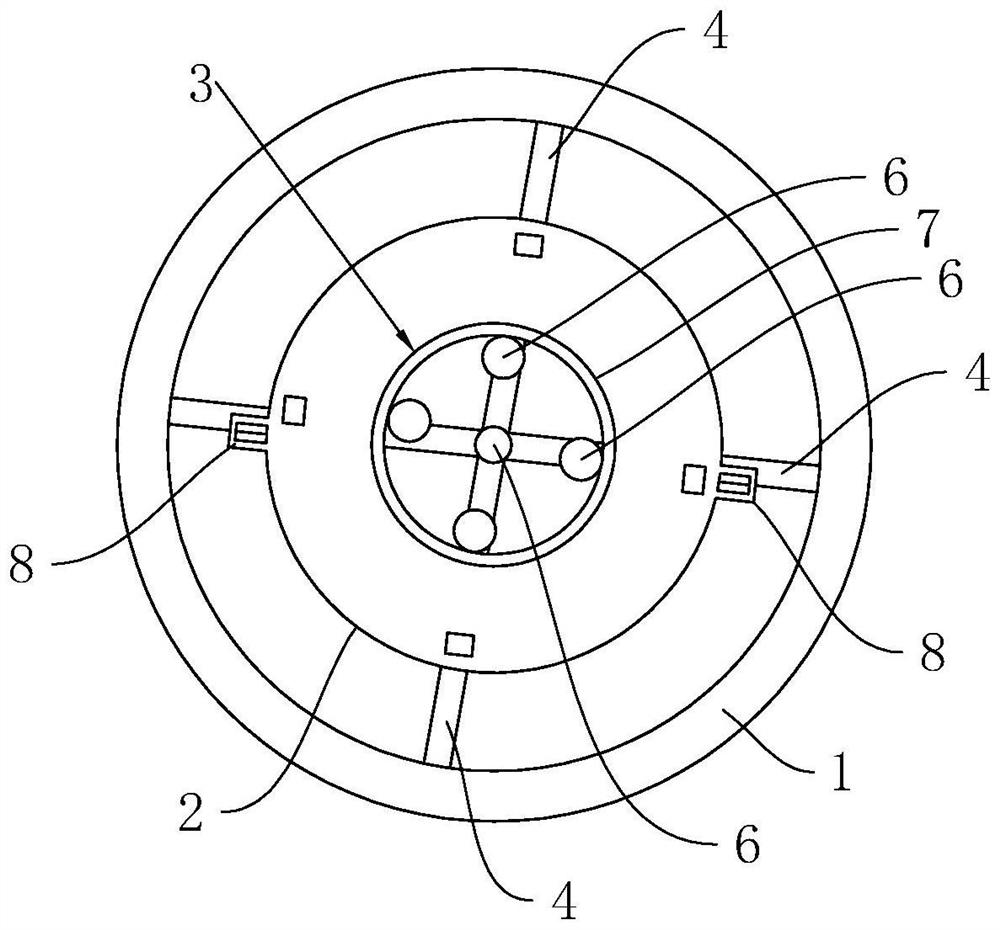

[0049] refer to figure 1 and figure 2, the embodiment of the present application discloses a prefabricated structural column, which is used to support the protective structure of underground construction, and can also become the main load-bearing column structure of later buildings. The above-mentioned prefabricated structural columns include cast-in-situ piles 1 and prefabricated pipes 2 . Among them, the cast-in-place pile 1 is a reinforced concrete cast-in-place pile with an open upper end and a hollow interior. The above-mentioned cast-in-place pile 1 is poured on the foundation, and the lower part of the cast-in-place pile 1 extends into the foundation and is stably connected with the foundation through pouring, thereby improving the overall prefabricated quality. Structural column stability. Secondly, a plurality of J-shaped embedded parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com