Gripping device for intelligently detecting full storage of container

A technology of intelligent detection and grasping device, which is applied to manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of complex structure, inaccurate detection, and inability to detect the amount of placed objects, and achieves high accuracy and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

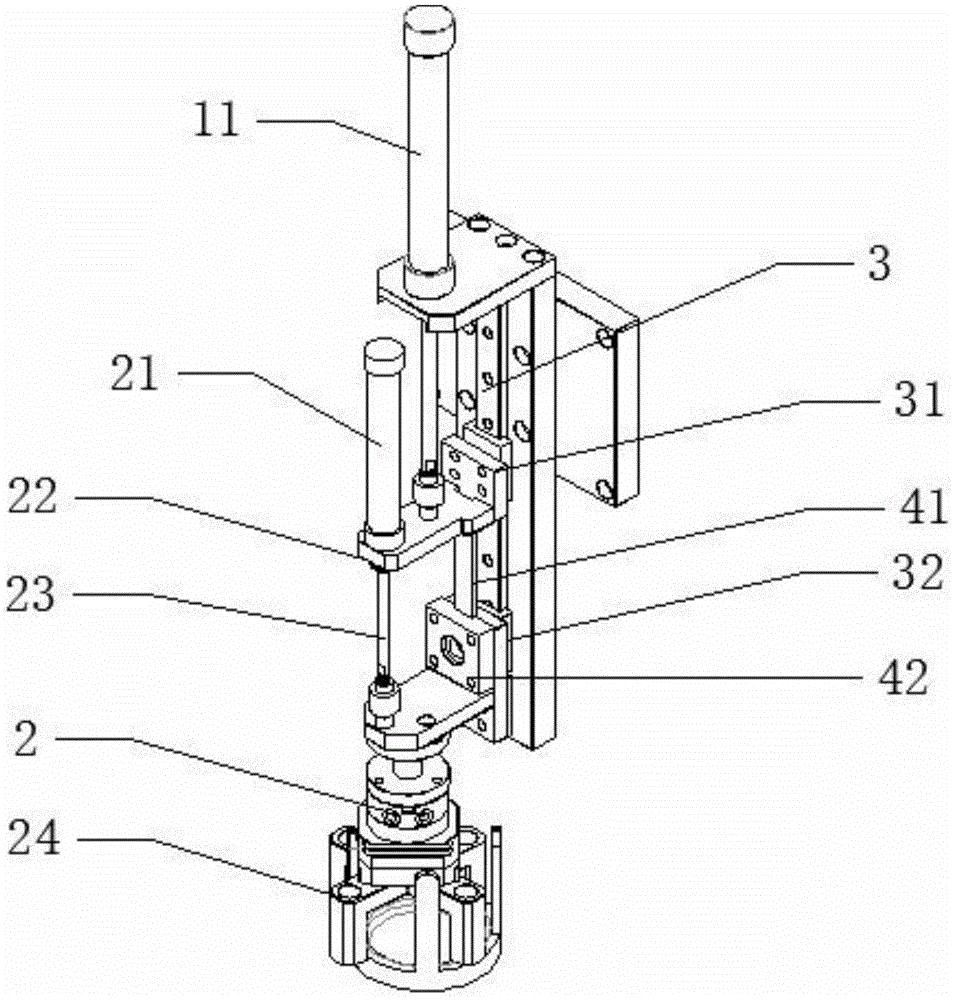

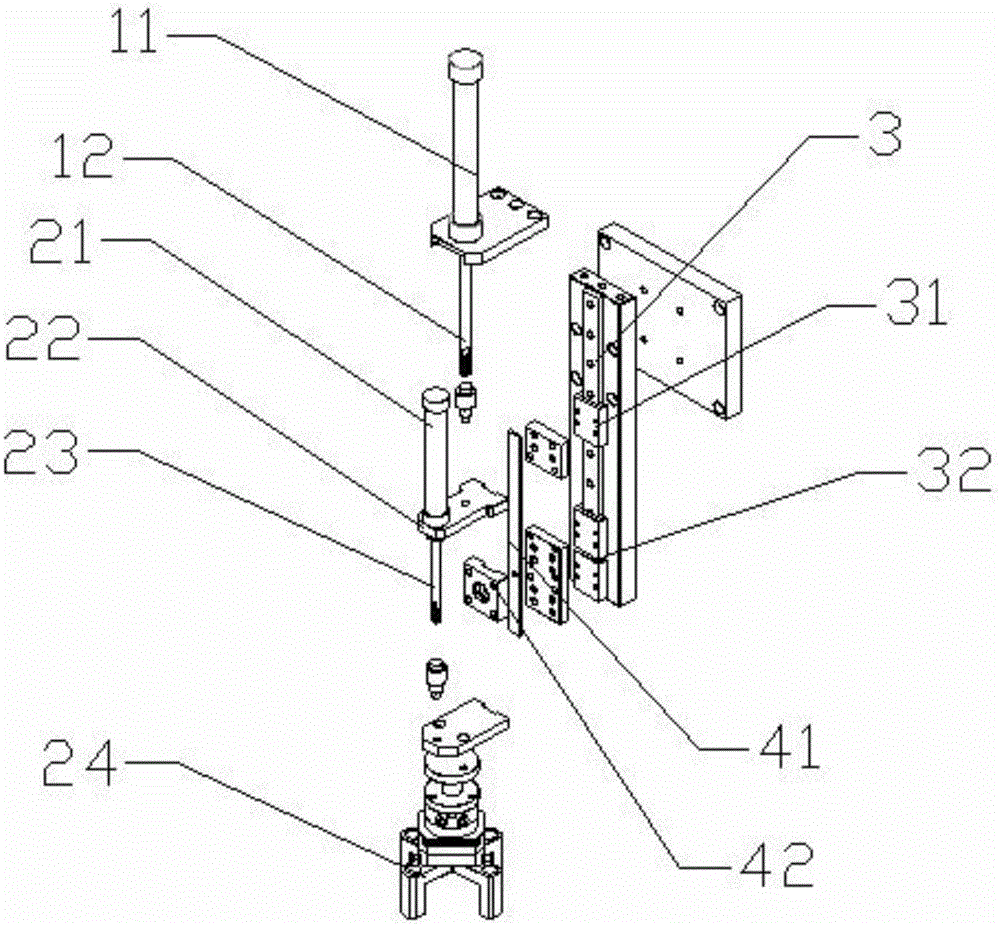

[0026] A grasping device that intelligently detects that the container is full, such as figure 1 , figure 2 As shown, it includes a grasping mechanism, a detection mechanism, a moving mechanism for controlling the movement of the grasping mechanism, a driving mechanism for driving the grasping mechanism to grasp or driving the moving mechanism to move, and a driving mechanism for sending a driving mechanism to the driving mechanism The control mechanism of instruction, it is characterized in that, described grasping mechanism comprises the grasper 24 that is used for grasping object, and described detection mechanism comprises telescoping mechanism and position sensor 27, and the protruding end of described telescoping mechanism and described grasping The telescopic mechanism is stretched under the gravity of the gripper 24 and shortened when the gripper 24 encounters dynamic resistance; the position sensor 27 is used to shorten the telescopic mechanism to a preset When the ...

Embodiment 2

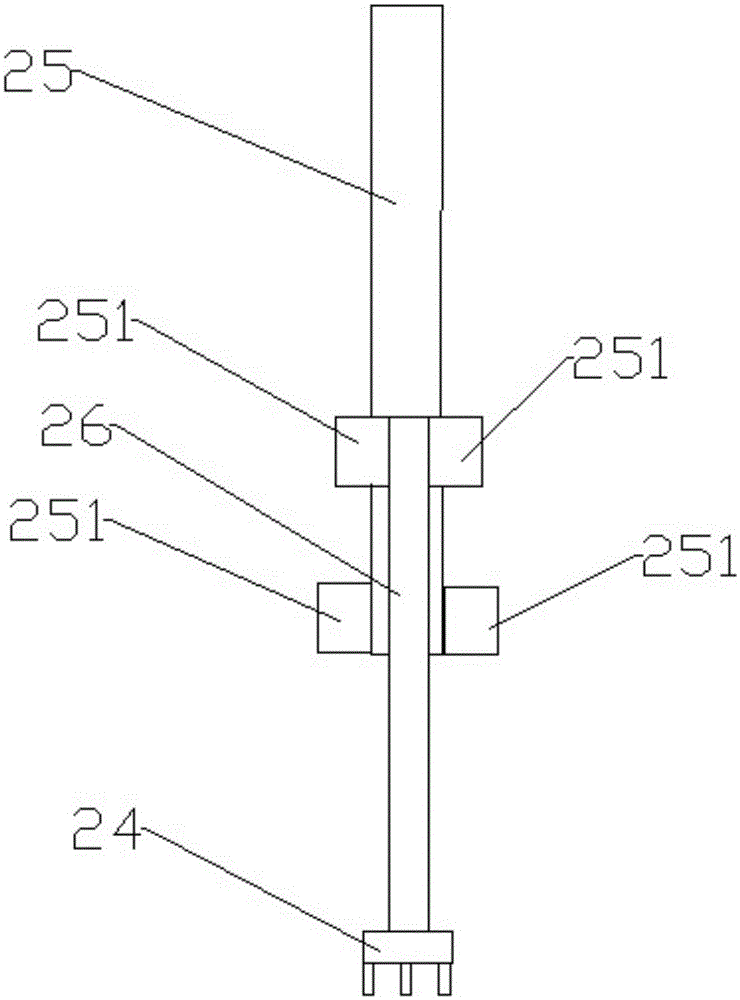

[0041] On the basis of the first embodiment, the second embodiment has been further improved, such as image 3 As shown, the telescoping mechanism is a slide rail 25 and a slide bar 26 vertically sliding on the slide rail 25 , and the slide bar 26 is connected with the gripper 24 .

[0042] When the position sensor 27 is a touch sensor, the position sensor 27 is arranged on the top of the guide rail 3, and the contact piece is arranged above the guide rail 3, and after the guide rail 3 rises for a predetermined distance, The position sensor 27 is in contact with the contact.

[0043]Certainly described position sensor 27 also can be located at the arbitrary position of guide rail 3 front, back, left and right four sides, and described contact member can be located on slide rail 25 and also can be located on other mechanism, as long as contact member is set Above the position sensor 27 , after the guide rail 3 rises a preset distance, it is sufficient for the position sensor 2...

Embodiment 3

[0045] On the basis of embodiment one, described embodiment three has been further improved, as Figure 4 As shown, the telescopic mechanism includes a cylinder body 21 and a telescopic rod 23 arranged in the cylinder body 21 , and the telescopic rod 23 is connected to the gripper 24 . The grabber 24 is subjected to dynamic resistance, and then the telescopic rod 23 moves upward and retracts into the cylinder body 21. When the telescopic rod 23 retracts a preset distance in the cylinder body 21, the position sensor 27 Send an object full signal to said control mechanism.

[0046] The position sensor 27 can be arranged inside the cylinder 21 or outside the cylinder 21 . When the position sensor 27 is a tactile sensor, preferably, one of the position sensor 27 and the contact member is arranged at the inner end 231 of the cylinder body of the telescopic rod 23, and the other is arranged at the cylinder body end 231 of the telescopic rod 23. 21 is the other end opposite to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com