Movable mechanism of printing nozzle and 3D printer with movable system

A 3D printer and mobile mechanism technology, applied in the field of 3D printing, can solve the problems of low printing efficiency, large space occupation, low accuracy rate, etc., and achieve the effect of reducing cost, good printing accuracy and high printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

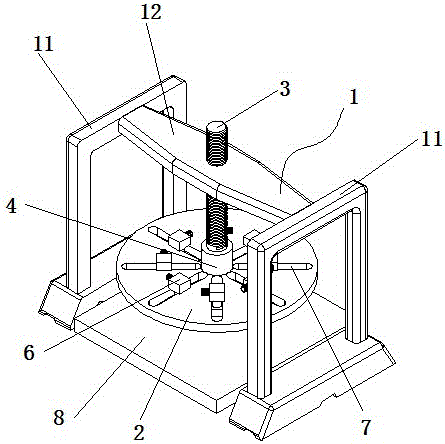

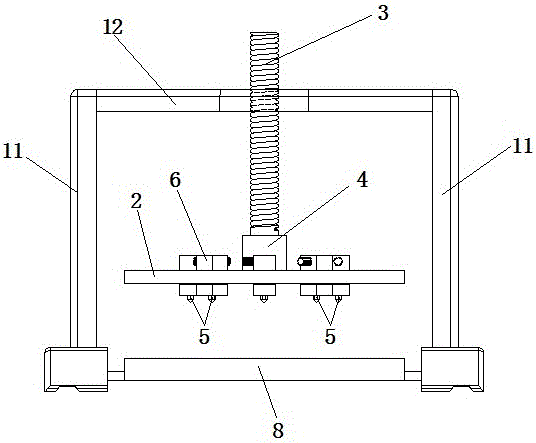

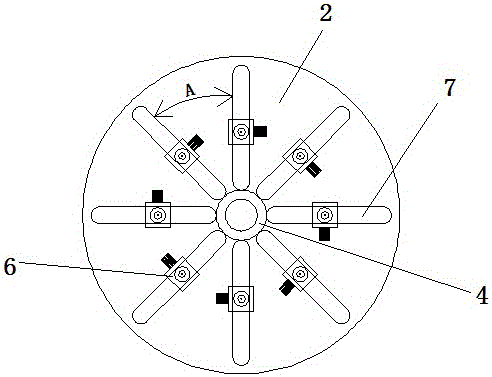

[0019] as attached Figure 1-3 As shown, a moving mechanism of a print nozzle is applied in a 3D printer. The moving mechanism includes a bracket 1, a turntable 2, and a lifting mechanism 3 that can move the turntable 2 up and down in the vertical direction. The above bracket 1 is connected, and the turntable 2 is installed on the lifting mechanism 3 through the rotating connector 4 (in this embodiment, the turntable 2 is installed on the lower end of the lifting mechanism 3 through the rotating connecting member 4), so that the turntable 2 It can rotate at any angle in the horizontal direction; N print nozzles 5 are arranged on the turntable 2, and N is a positive integer. When N is equal to 1, the print nozzle 5 is arranged on a slider 6, and the slider 6 is set In a chute 7 provided on the turnta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com