Thread cap arrangement mechanism

A threaded cap and threaded connection technology, which is applied in the direction of threaded caps, conveyor objects, transportation and packaging, etc., can solve the problems of bottle caps, bottle caps falling, high scrap rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

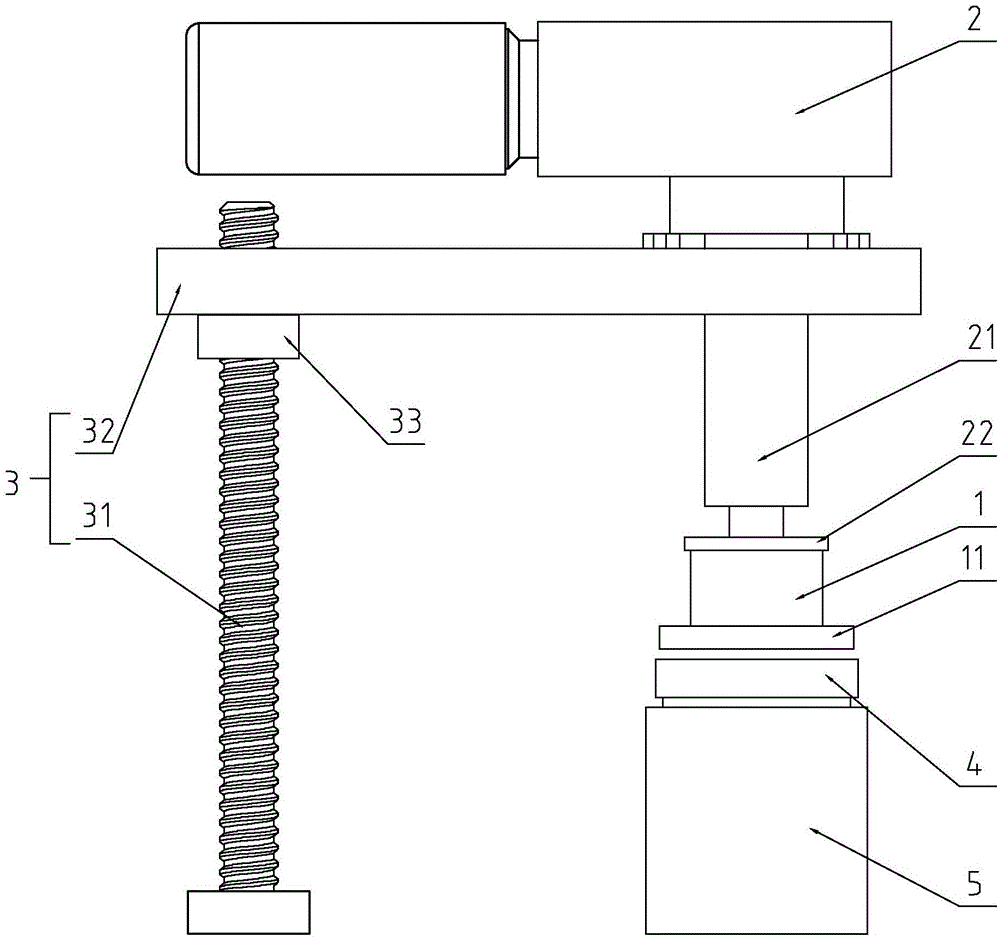

[0017] refer to figure 1 The embodiment of the whole screw cap mechanism of the present invention will be further described.

[0018] A screw cap whole cap mechanism, comprising an adjustment part 1 and a power part that drives the adjustment part 1 to rotate, the rotation direction of the adjustment part 1 is opposite to that of the internal thread of the bottle cap 4, and the adjustment part 1 is used to interfere with the bottle cap 4 to make the It can be squared on the bottle mouth. Place the screw cap whole capping mechanism between the capping device and the capping device, place the bottle cap 4 on the opening of the bottle body 5 through the capping device, and then transfer it to the processing area of the screw cap whole capping mechanism through the conveyor belt, here What needs to be disclosed is: the rotation axis of the adjustment part 1 is set to coincide with the axis of the bottle body 5, and the height of the adjustment part 1 is adjusted so that it just...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com