Discharging device for electronic product production line

A technology for electronic products and production lines, which is applied in the field of blanking devices of electronic product production lines, can solve the problems of packaging troubles, easy collision and damage, and achieve the effect of improving packaging efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

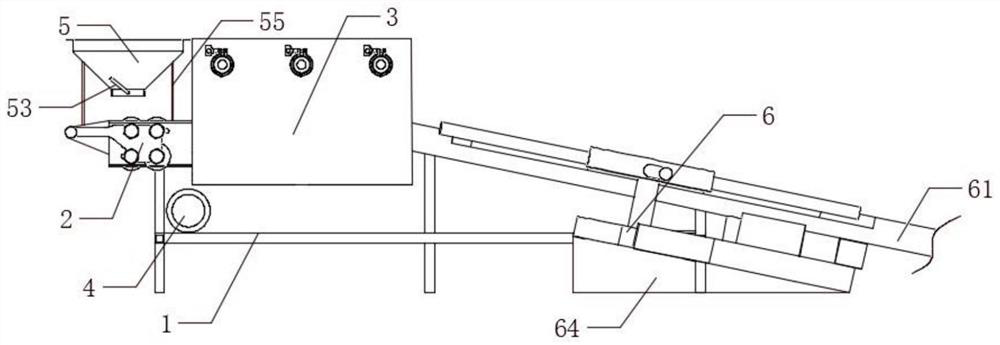

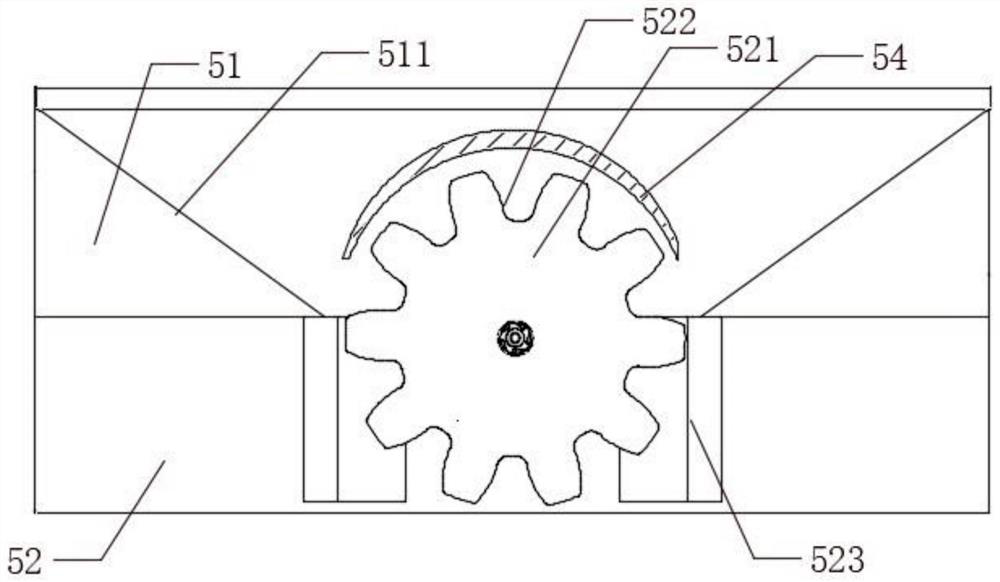

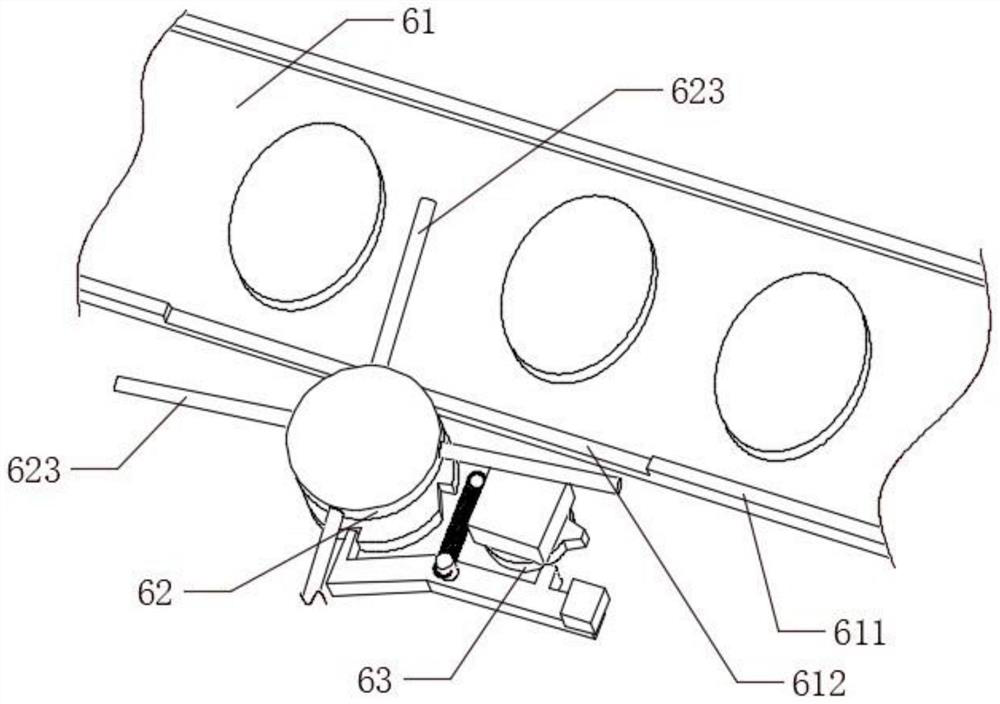

[0032] Such as Figure 1-Figure 5As shown, a blanking device for an electronic product production line according to the present invention includes a platform 1, a conveying assembly 2 located on the upper part of the platform 1, a blanking assembly 5 connected to the upper end of the head of the conveying assembly 2, and a blanking assembly 5 arranged in the material conveying direction. The detection assembly 3 is connected to the two sides of the transmission assembly 2, and the lower part of the transmission assembly 2 is provided with a drive assembly 4 connected to the platform 1. The drive assembly 4 provides a power source for the transmission assembly 2 and drives the material to be transported to the detection assembly 3. The blanking assembly 5 has an upper introduction layer 51 and a lower distribution layer 52. After the material is placed from the upper end of the blanking assembly 5, it enters the lower distribution layer 52 through the upper introduction layer 51...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com