Arc-shaped pressing bar device for selvedge suction device temples

A technology of arc-shaped beading and edge suction device, which is applied in the direction of textile, textile, papermaking, loom, etc., can solve the problem that the rough edges are easy to warp, affect the working efficiency and product quality of the whole machine, and the function of the edge suction device cannot be effectively exerted and other problems, to achieve the effect of solving the missing cutting of the weft end, improving work efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

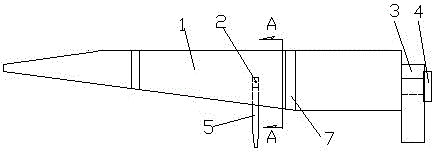

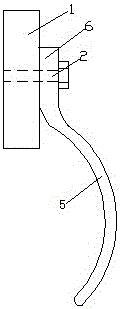

[0013] Embodiments of the present invention refer to figure 1 , figure 2 , use the second screw 4 to install and fix the temple 1 in the open groove on the left and right temples 3 of the edge absorber of the shuttleless loom; the tail handle 6 of the arc-shaped bead 5 is provided with a hole, and the arc-shaped bead 5 tail end The thickness is greater than the thickness of the front end, and one end of the arc bead 5 is connected with the tail handle 6 to form an arc bead; the first screw is inserted in the hole on the arc bead tail handle 6, and the arc bead 5 is installed and fixed on the left and right sides respectively. On the bottom surface of the temple 1, an arc-shaped beading device for the temple of the side suction device is formed.

[0014] Arc bead 5 is made of spring steel bar, is respectively installed and fixed on the arc bead 5 on left and right two temples 1 bottom surface, and its structure and effect are identical.

[0015] Reinforcing ribs 7 are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com