Construction method for laying suspension bridge catwalk

A construction method and technology of suspension bridges, applied in bridge construction, bridge, erection/assembly of bridges, etc., to achieve the effect of simple process and reducing the risk of high-altitude operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

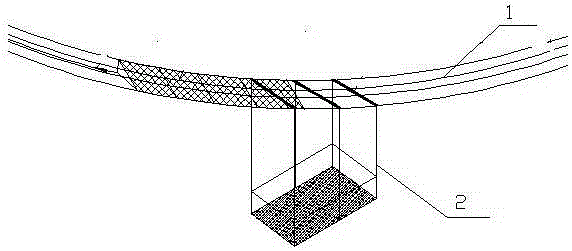

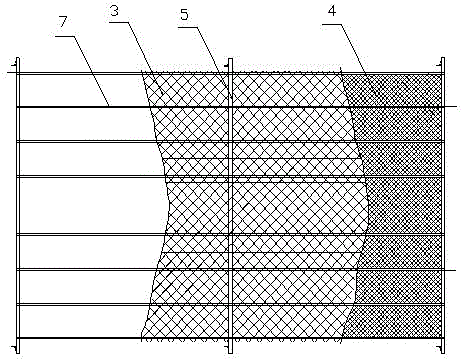

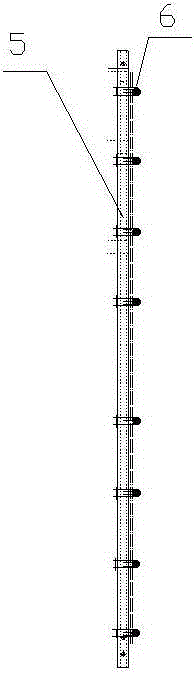

[0039] Such as figure 1 — image 3 As shown, a construction method for laying a suspension bridge catwalk in this embodiment, this construction method has changed the traditional slide-down laying method from a high place to a low place, and adopts a pull-up laying method from a low place to a high place , the method mainly includes the following steps:

[0040] Step 1. Erection of catwalk load-bearing cables

[0041] The catwalk load-bearing cables are erected between the cable towers of the suspension bridge, and the verticality of the load-bearing cables is adjusted according to the actual situation to facilitate the subsequent laying of the catwalk surface.

[0042] Step 2. Install the operating platform and power equipment

[0043] Use the bracket to install the hanging basket at the lowest point where the load-bearing cable is away f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com