Throwing lever anti-collision device, throwing lever assembly and anti-collision gate

An anti-collision device and gate lever technology, applied in the field of barrier gates, can solve the problems of reducing the degree of automatic operation of barrier gates, inconvenient use, etc., and achieve the effect of convenient use and anti-collision damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

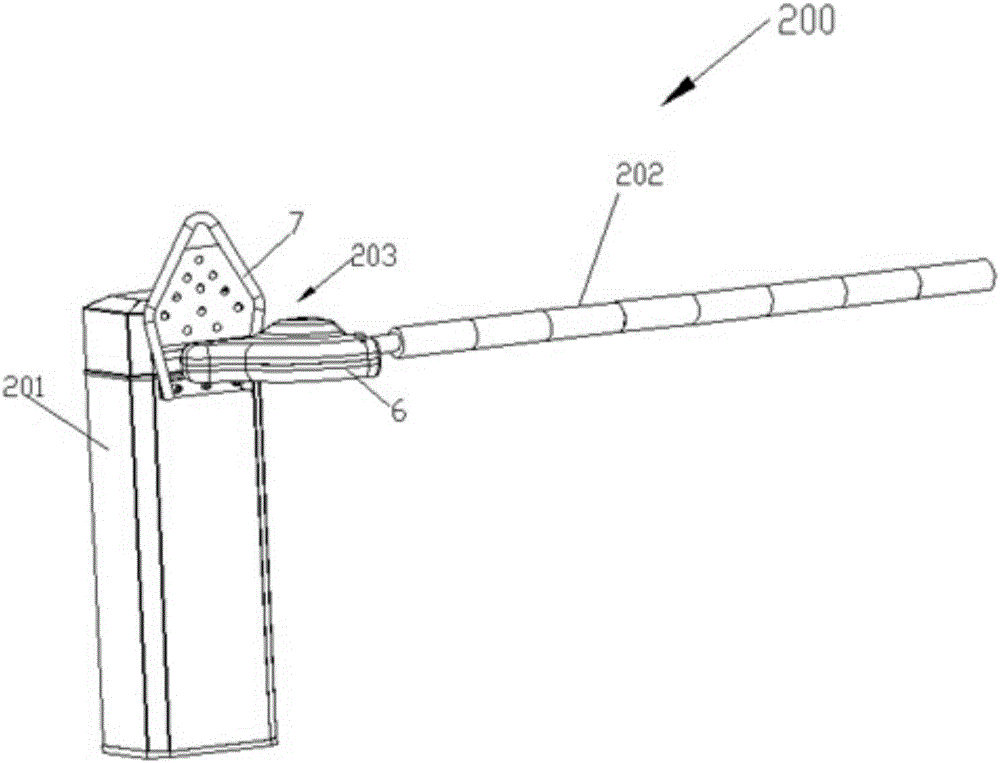

[0027] Such as figure 1 As shown, the anti-collision barrier barrier 200 includes a barrier barrier chassis 201, a control unit, a drive unit and a brake lever assembly. Both the control unit and the drive unit are installed on the barrier gate chassis 201 . The drive unit protrudes a rotatable main shaft from the barrier gate housing 201 . The brake lever assembly includes a brake lever 202 and a brake lever anti-collision device 203 .

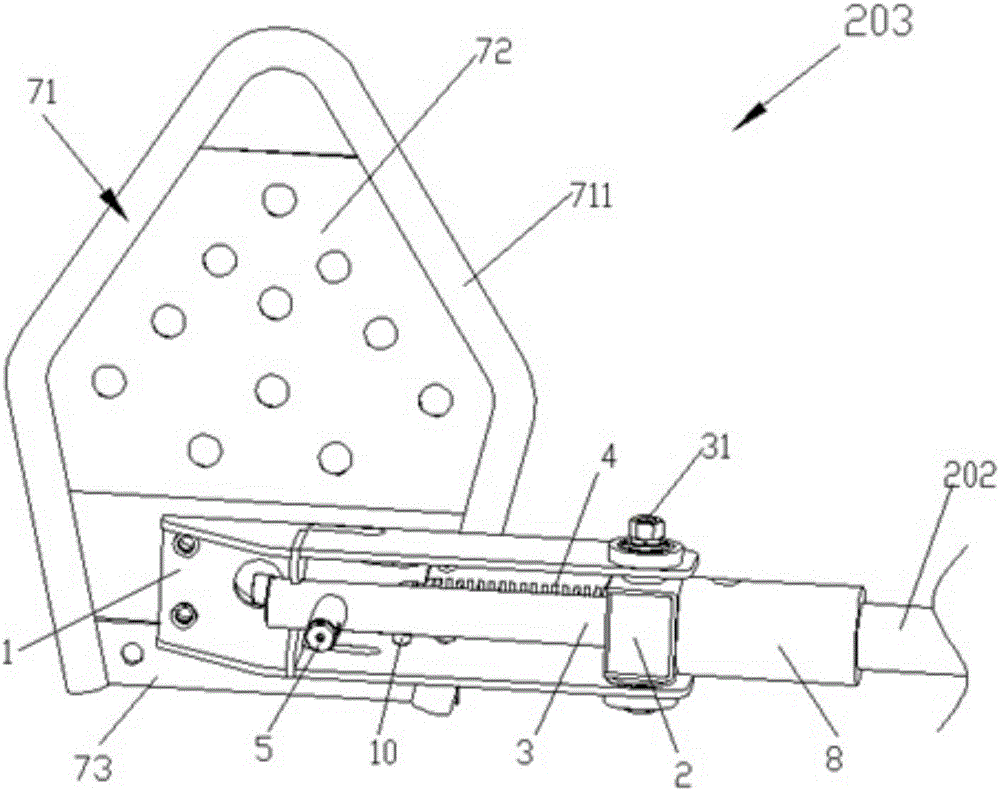

[0028] Such as figure 1 and 2 As shown, the brake lever anti-collision device 203 includes a chuck 1 , a clamp block 2 , a swing shaft 3 , a spring 4 , a spring mounting part, a position sensing part, a buffer 5 , a case 6 , a guide frame 7 and a guide post 8 .

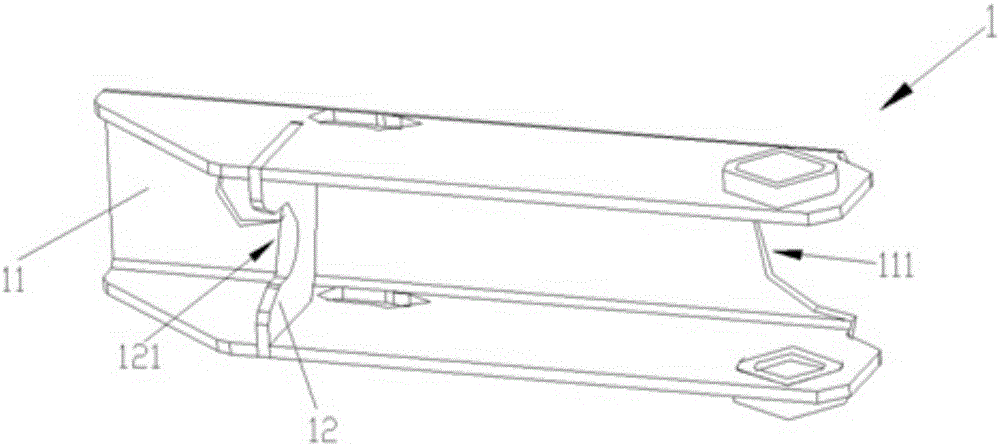

[0029] Such as image 3 As shown, the chuck 1 includes a chuck body 11 , a seat plate 12 and a chuck seat. The chuck main body 11 is a shell structure with three sides open. The rear side wall of the chuck main body 11 is fixedly connected to the main shaft through the chuck s...

Embodiment 2

[0045] In Embodiment 2, the brake lever anti-collision device has the same structure as Embodiment 1, and also includes two clamping units 13 . The structures in the second embodiment that are the same as those in the first embodiment are assigned the same numbers, and descriptions thereof are omitted.

[0046] Such as Figure 8 As shown, each clamping unit 13 includes an elastic steel sheet 131 and a nylon block 132 . Two elastic steel sheets 131 are symmetrically installed on the upper surface and the lower surface of the limit block 91 , and the nylon block 132 is connected to the front side of the elastic steel sheet 131 and leans against the surface of the balance shaft 3 . The distance between the nylon blocks 132 on the upper and lower sides is slightly smaller than the diameter of the pendulum shaft 3, so that the pendulum shaft 3 is clamped. When the vehicle hits the brake lever 202 forward, the pendulum shaft 3 squeezes the nylon block 132 to the front side, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com