Cast-in-place outdoor step member and method of decreasing differential settlement between outdoor step member and main building

A technology for outer steps and steps is applied in the field of reducing the differential settlement between reinforced concrete outdoor steps and the main building, and in the field of cast-in-place reinforced concrete outdoor steps. The ability to increase the resistance to deformation, the effect of improving stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

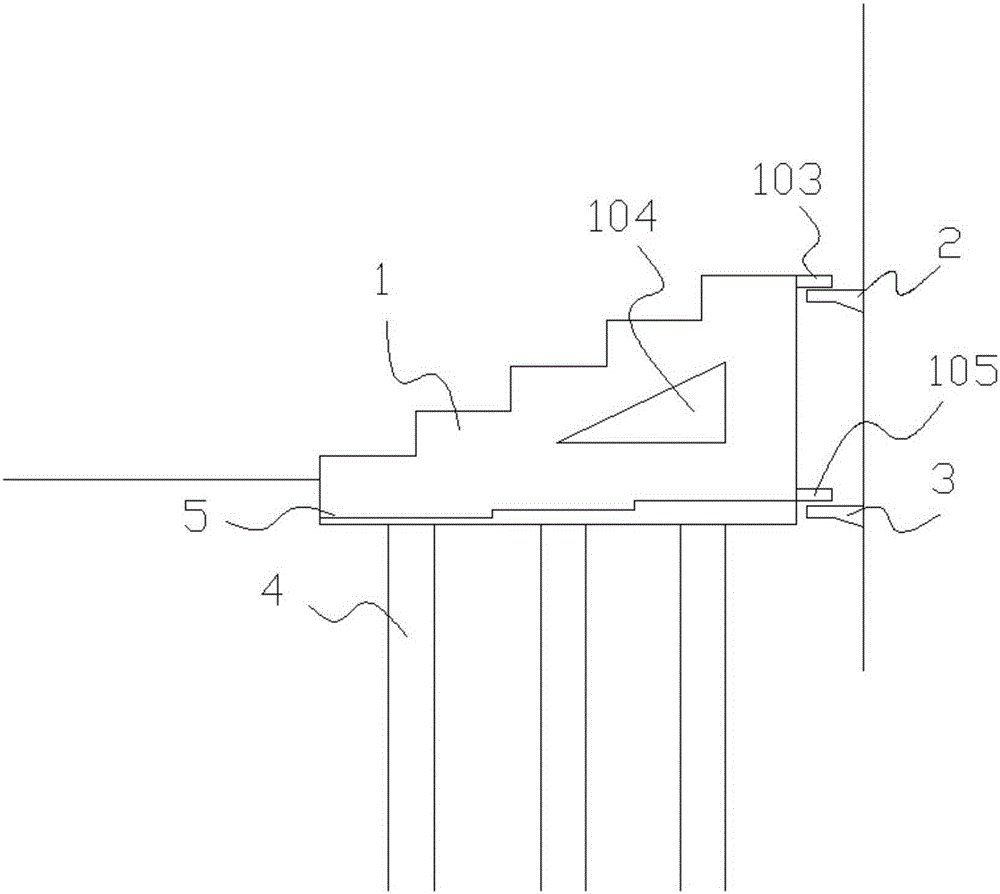

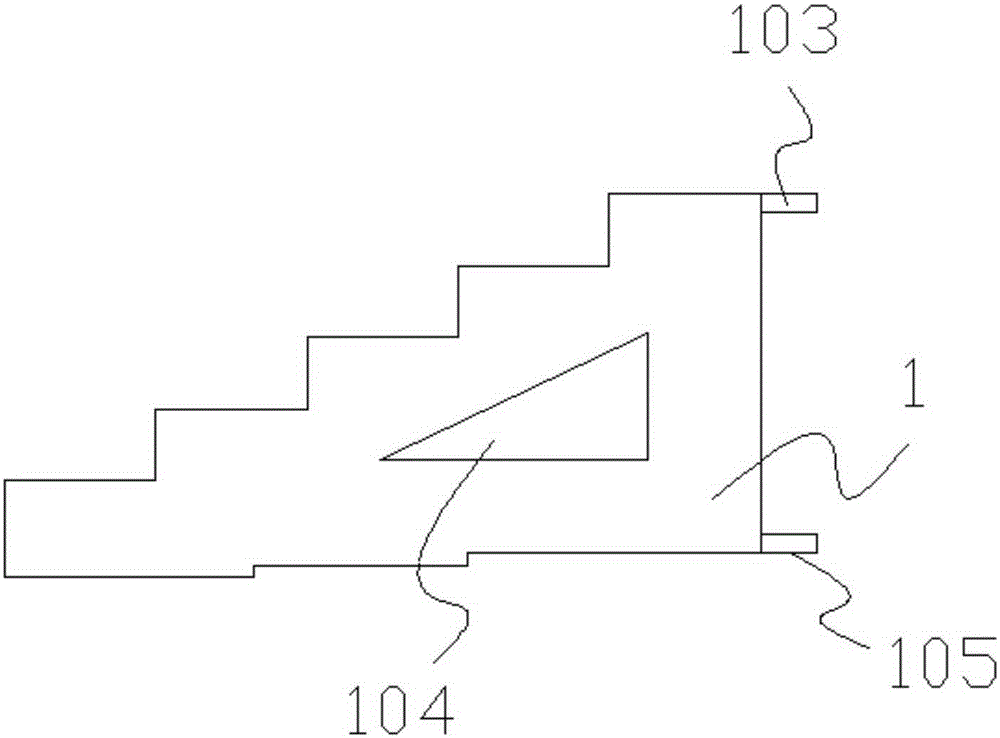

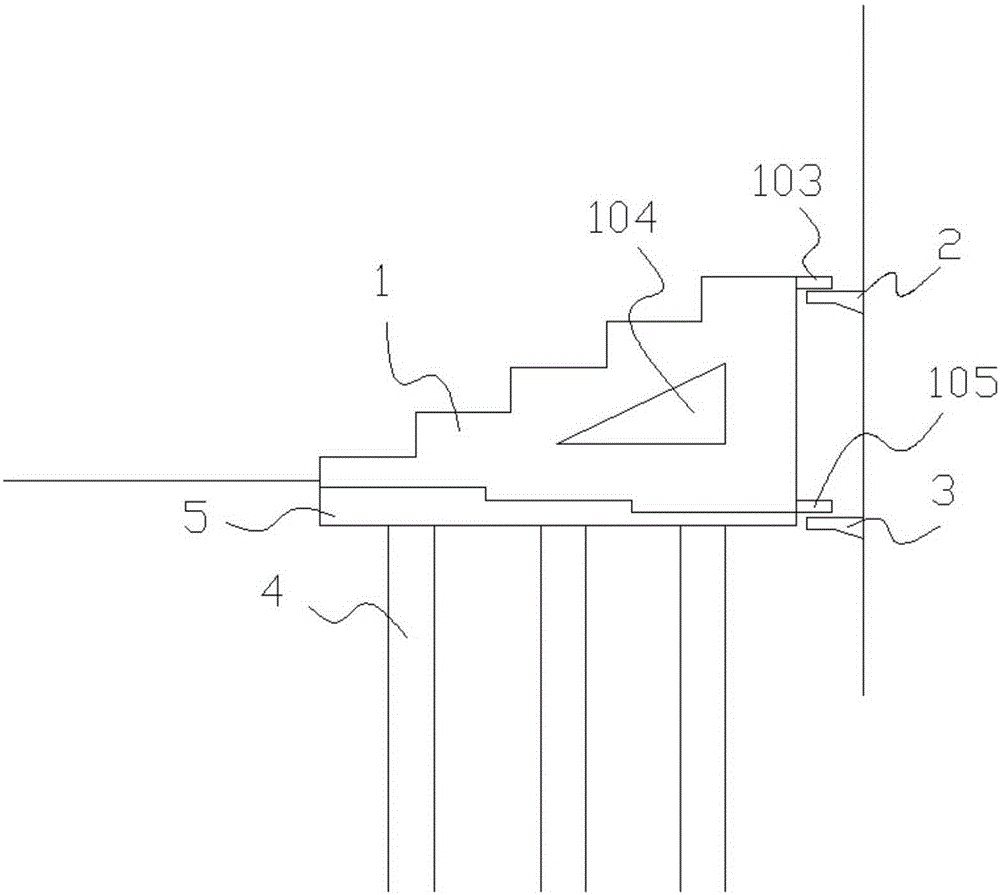

[0029] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0030] The cast-in-place reinforced concrete outdoor steps include the reinforced concrete outdoor steps 1, and the upper support 2 and the lower support 3 arranged on the main building. The bottom surface of the reinforced concrete outdoor steps 1 is stepped, and the back of the reinforced concrete outdoor steps 1 The upper part of the outdoor step 1 is provided with an upper step connector 103, the lower part of the back of the reinforced concrete outdoor step 1 is provided with a lower step connector 105, the upper step connector 103 is arranged on the upper support 2, and the lower step connector 105 is arranged on the lower support 3, also includes the concrete leveling cushion poured on the foundation 5, the PVC pipe pile or PP-R pipe pile 4 placed underground, the mortar or fine stone filled in the PVC pipe pile or PP-R pipe pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com