Buckle structure

A technology of snap structure and single structure, which is applied in the direction of connecting members, shrinking connections, mechanical equipment, etc., can solve the problems of easy slipping of male buckles, squeezing deformation of female buckle accommodation space, low efficiency, etc., so as to avoid scratches. Or tingling, tightening fit and tightening is stable, and the fixing effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention are described in detail below:

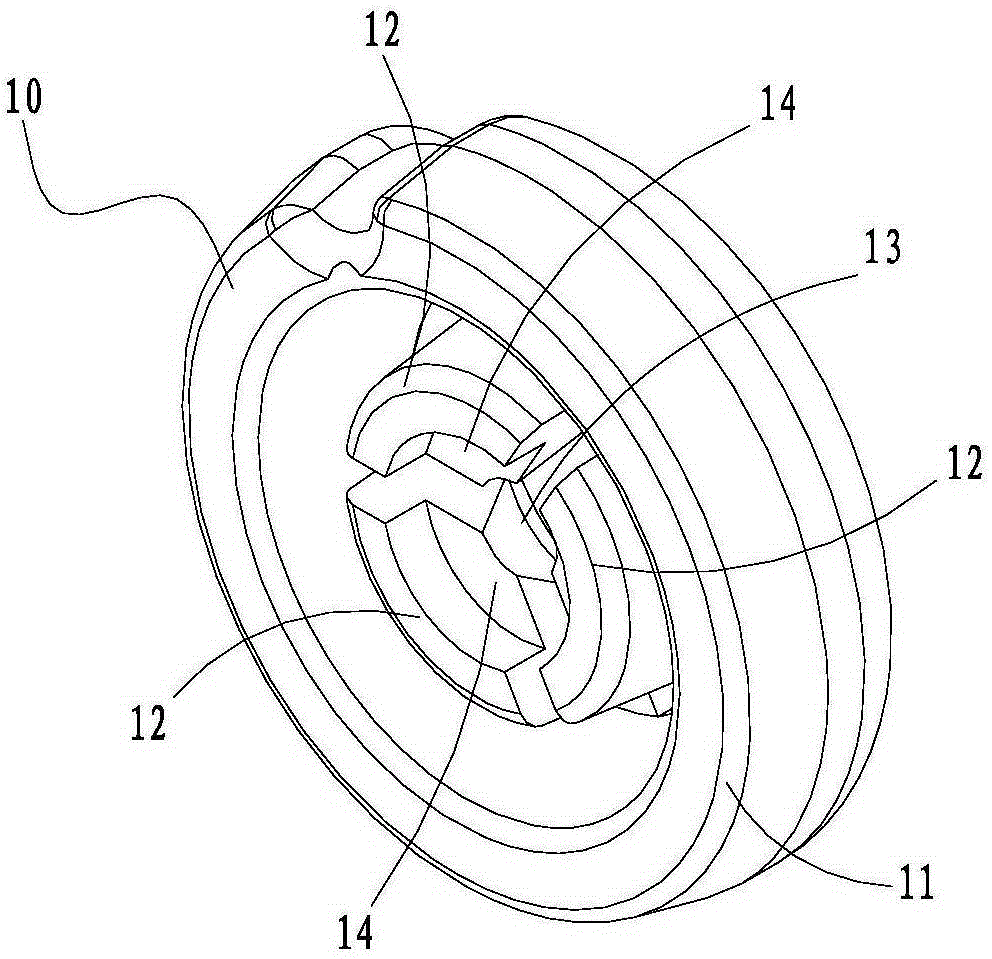

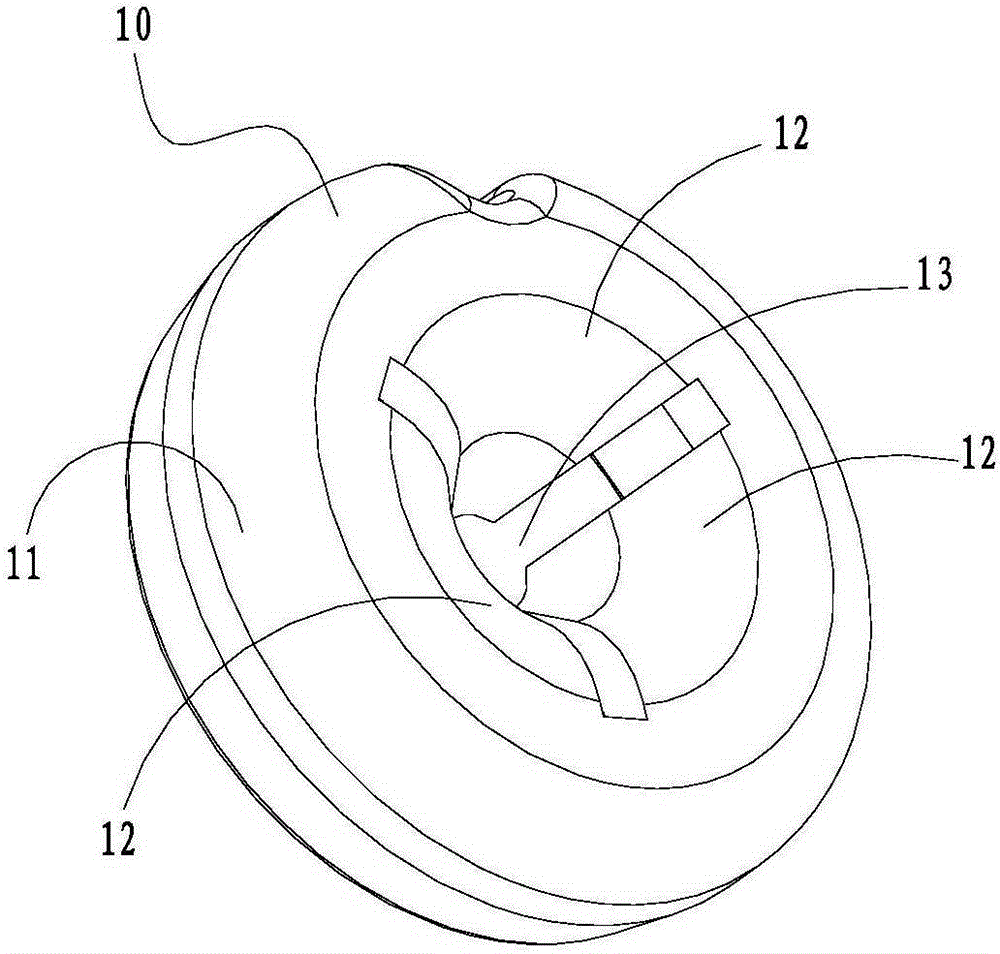

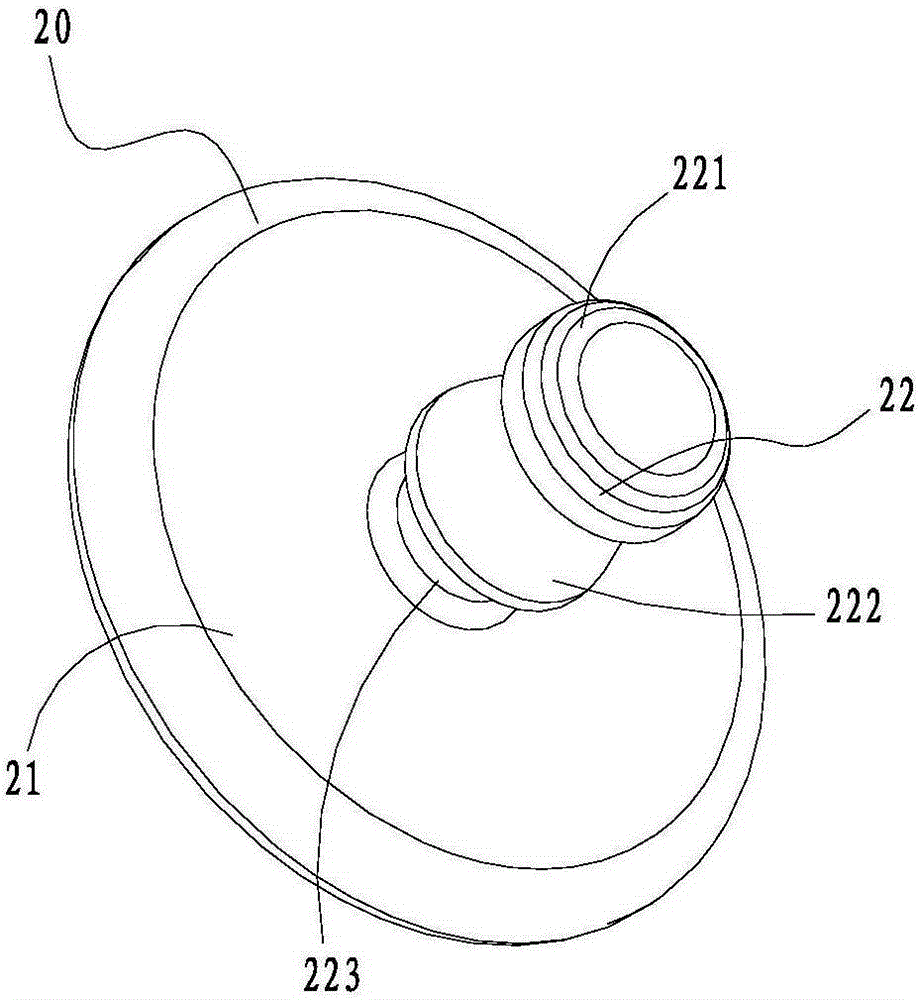

[0034] Figure 1-2 Schematically shows the structural diagram of the female snap 10 in the present invention, Figure 3-5 Then schematically shows the structure diagram of the male buckle 20 in the present invention. The buckle structure of the present invention includes a female buckle 10 and a male buckle 20 . Both the female buckle 10 and the male buckle 20 are elastic rubber materials. see Figure 1-2 , the female buckle 10 includes a cylindrical body 11 and more than two inner teeth 12 connected with the cylindrical body 11 . More than two internal teeth 12 are arranged around the cylinder body 11 . The internal teeth 12 are arranged along the axial direction of the barrel 11 . The part where the cylinder body 11 is connected to the inner teeth 12 is elastic. There is a space between the side parts of the adjacent internal teeth 12 or they are connected by a soft body. An insertion channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com