Moving-shaft type power transmission applied to hole digger for southern mountainous gardens

A technology for digging machines and transmissions, which is applied to mechanical equipment, transmissions, transmission parts, etc. It can solve the problems of shortened service life and wear of transmissions, and achieve the effect of improving stability and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

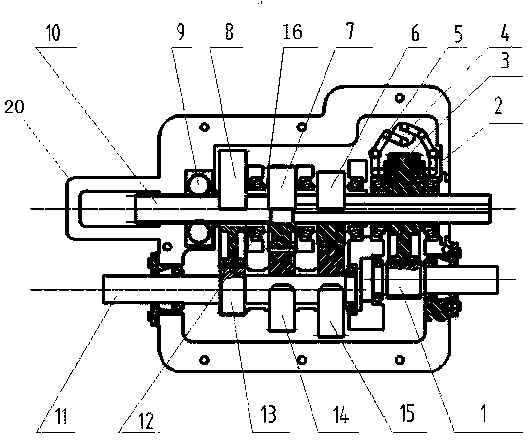

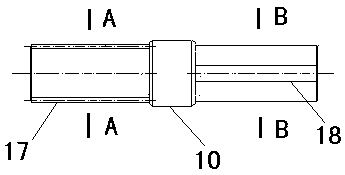

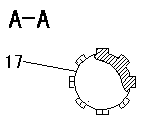

[0021] The following will be combined with Figure 1-8 The beneficial effects of the present invention are described in detail, aiming at helping readers better understand the essence of the present invention, but not limiting the implementation and protection scope of the present invention.

[0022] The upper end of the inner cavity of the housing 20 is provided with a moving shaft 10, the lower end of the inner cavity of the housing 20 is provided with an output shaft 11 and an input shaft, one end of the input shaft is connected to the input gear 1, and the input gear 1 is connected to the intermediate gear 2 , the two sides of the intermediate gear 2 are provided with grooves, and the brake rubber arc strip 3 is arranged directly above the groove, and the outer side of the brake rubber arc strip 3 is connected to one end of the brake connecting rod 5. The other end of the brake connecting rod 5 is connected to the brake small turntable 4, and the brake small turntable 4 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com