Method and device for detecting sizes of polaroid

A detection method and detection device technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of heavy polarizing plates, manpower and equipment production capacity loss, and cannot be predicted in advance, so as to ensure timeliness and reduce product quality. effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

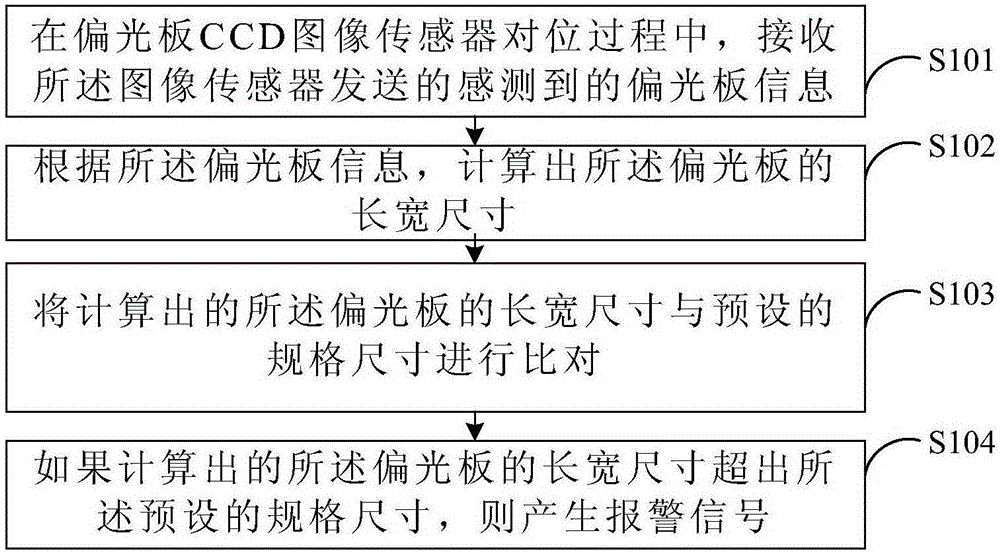

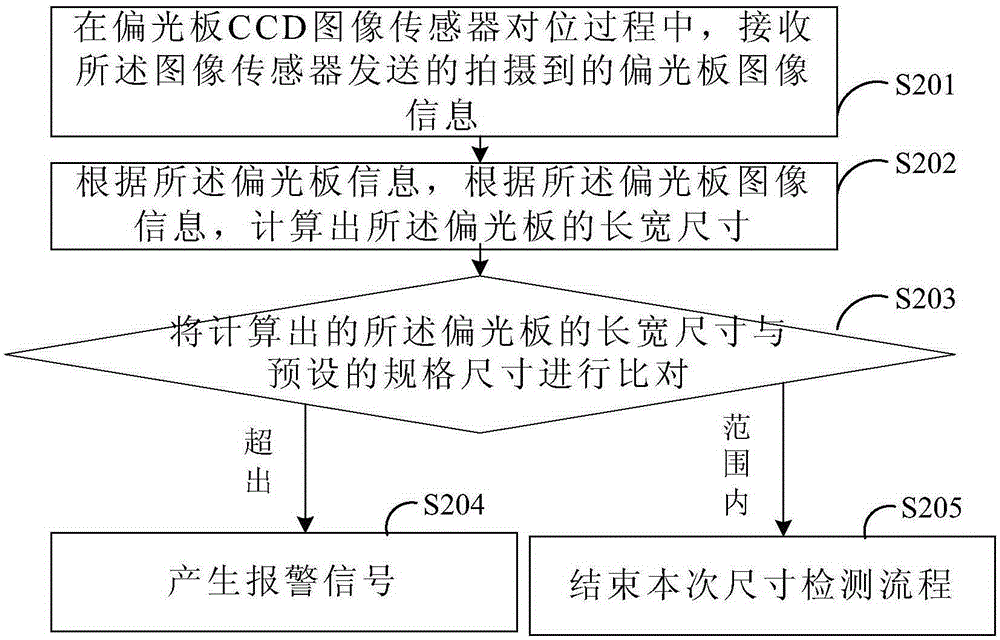

Embodiment 1

[0060] see figure 2 , is the implementation process of the detection method for the size of the polarizer provided in Embodiment 1 of the present invention, which mainly includes the following steps:

[0061] In step S201, during the alignment process of the polarizing plate CCD image sensor, receiving the image information of the polarizing plate sent by the image sensor;

[0062] In step S202, the length and width dimensions of the polarizer are calculated according to the image information of the polarizer;

[0063] In step S203, comparing the calculated length and width dimensions of the polarizing plate with preset specifications;

[0064] In step S204, if the calculated length and width dimensions of the polarizer exceed the preset specifications, an alarm signal is generated.

[0065] In step S205, if the calculated length and width dimensions of the polarizing plate are within the preset specification dimensions, then the dimension detection procedure ends.

Embodiment 2

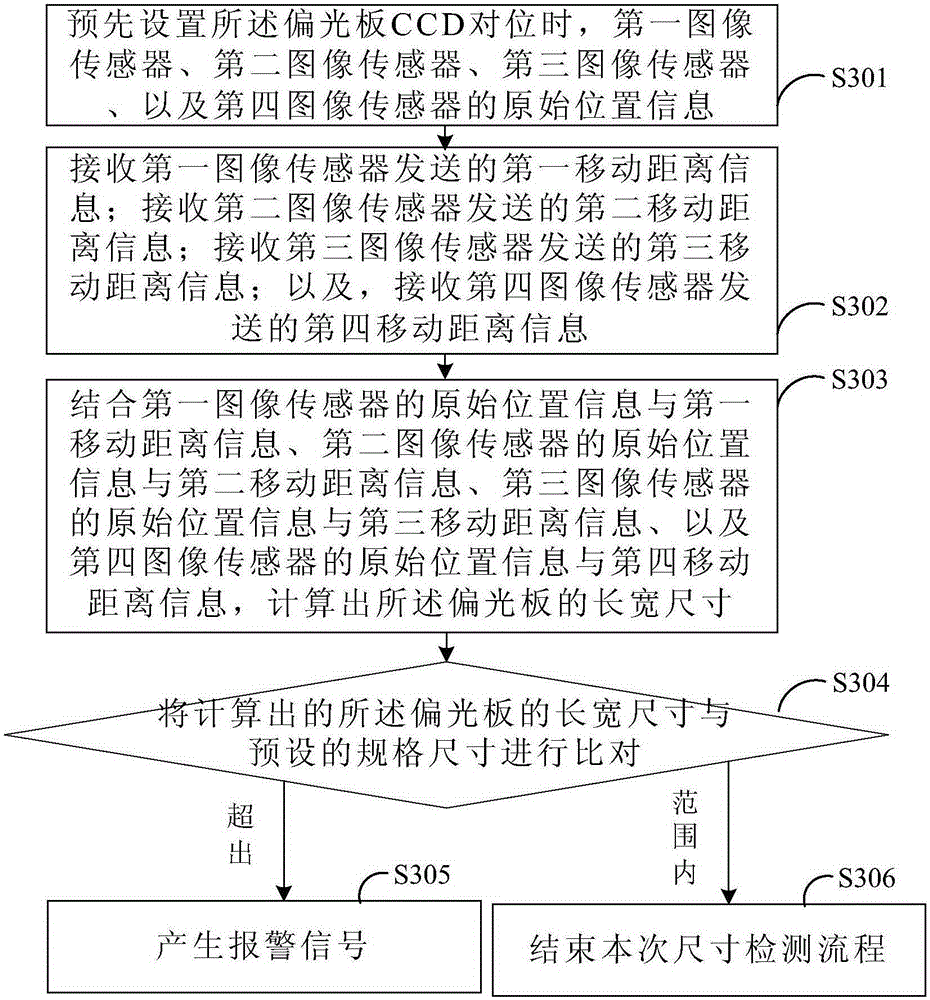

[0067] see Figure 3A , is the implementation flow of the detection method for the size of the polarizer provided in Embodiment 2 of the present invention, which mainly includes the following steps:

[0068] In step S301, the original position information of the first image sensor, the second image sensor, the third image sensor, and the fourth image sensor when the polarizing plate CCD is aligned in advance;

[0069] In step S302, during the alignment process of the polarizing plate CCD image sensor, the first moving distance information sent by the first image sensor is received; the second moving distance information sent by the second image sensor is received; the second moving distance information sent by the third image sensor is received. 3. moving distance information; and, receiving fourth moving distance information sent by the fourth image sensor;

[0070] In the embodiment of the present invention, please refer to Figure 3B , is a schematic distribution diagram ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com