Determination method and testing apparatus for permeability coefficient of cement-based material

A technology of cement-based material and permeability coefficient, which is applied in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1 cement-based material permeability coefficient determination test method of the present invention, comprises the following steps:

[0043] 1) Pretreatment of the test piece: seal the side wall of the test piece after curing with paraffin;

[0044] 2) Install the test barrel: install the pretreated test piece in the test barrel to ensure that the contact between the test piece and the test barrel and the entire test barrel are completely sealed; The pressure unit is connected, and the water outlet valve of the test barrel is connected with the water seepage measurement unit;

[0045] 3) After the test barrel is installed, fill the test barrel with water through the water inlet pipe until water seepage occurs in the exhaust and drain valve, stop the water injection,

[0046] After setting the pressure parameters on the controller panel, start the program, start the booster pump, wait until the reading increase rate in the water seepage measurement unit reach...

Embodiment 2

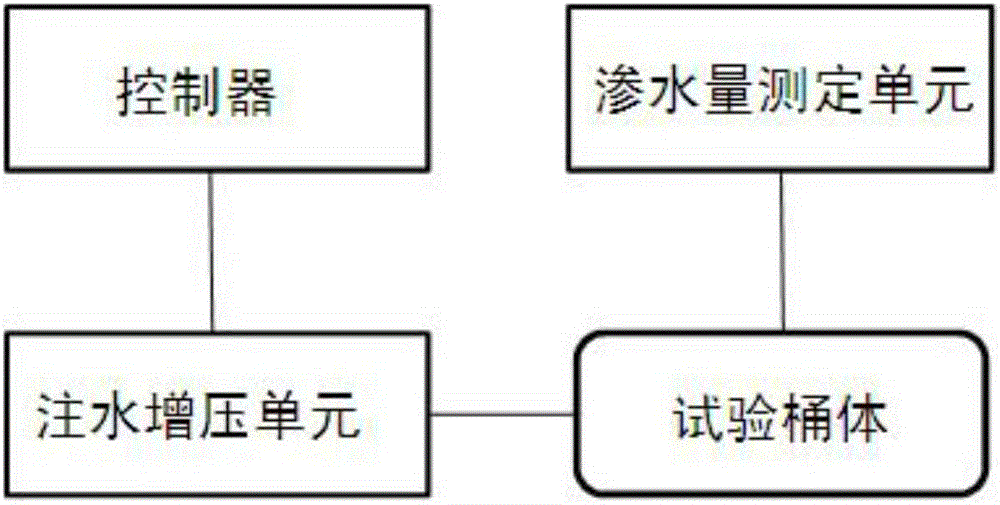

[0054] Example 2 The test device constructed according to the test method described in Example 1, including a test barrel, a water injection pressurization unit, a water seepage measurement unit and a controller with a control panel, and the test piece is housed in the test barrel 24. The water inlet of the test barrel is connected with the water injection pressurization unit; the water seepage measurement unit is connected with the water outlet valve 27 of the test barrel; the controller includes a time control unit 36 and a pressure control unit 37, the signal input end of the pressure control unit is connected to the pressure sensor 38 arranged in the test barrel, the signal output end of the controller is connected to the booster pump 11 of the water injection booster unit The control terminal is connected, and the signal input and output terminals of the time control unit and the signal input and output terminals of the pressure control unit are connected to the control te...

Embodiment 3

[0069] Embodiment 3 Below with measuring water-cement ratio 0.45, aggregate content 50%, curing age is 28d, and height is 50mm, and diameter is that the permeability coefficient measurement of 250mm concrete specimen under constant pressure 1.0MPa is example, to the work of the present invention The process is described in detail as follows:

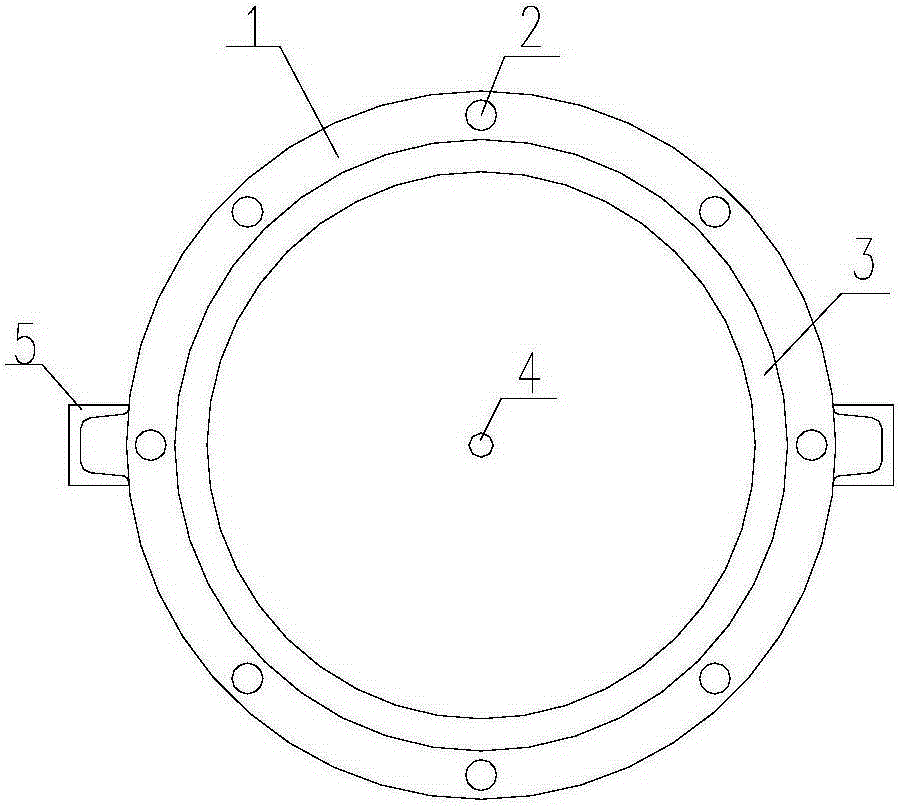

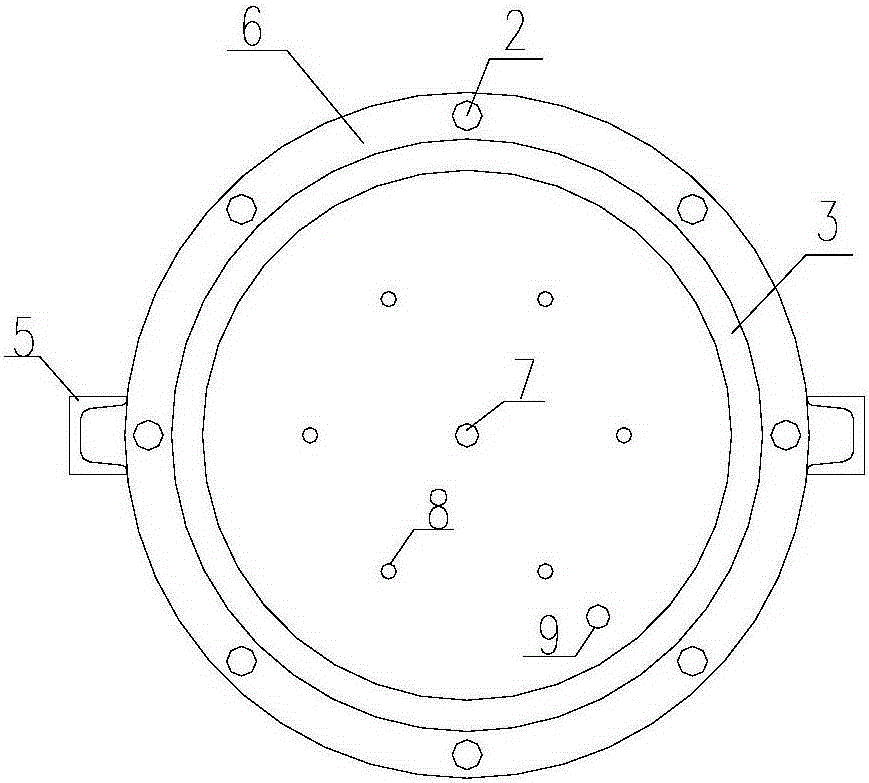

[0070] Before the test starts, the size is After standard curing for 28 days, the test piece was taken out from the curing room and the surface moisture was dried, then 50mm of each end was cut off with a cutting machine, and the side wall of the cylindrical test piece was sealed with paraffin. According to the needs of the test, select the sealing ring Ⅱ18 of the corresponding specification, according to Figure 5 As shown, the test piece 24 is sealed between the top (bottom) plate 6 and the central opening pressure plate 23. After the test piece is sealed, according to Image 6 As shown, the second cover plate 1 equipped with the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com