Method for determining reactive dye fixation rate through K/S value coating method

A technology of reactive dyes and color fixation rate, which is applied in the field of textile printing and dyeing, can solve the problems of determining the color fixation rate of reactive dyes, cumbersome operation, poor accuracy, etc., and achieve the effect of accurate color fixation rate of reactive dyes and direct method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

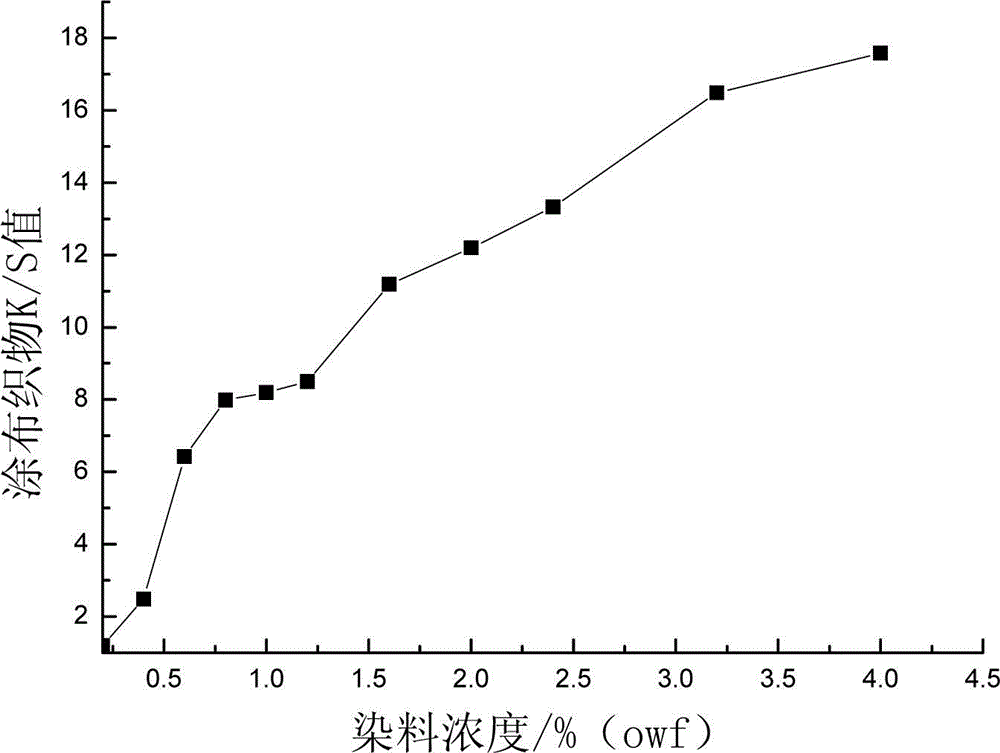

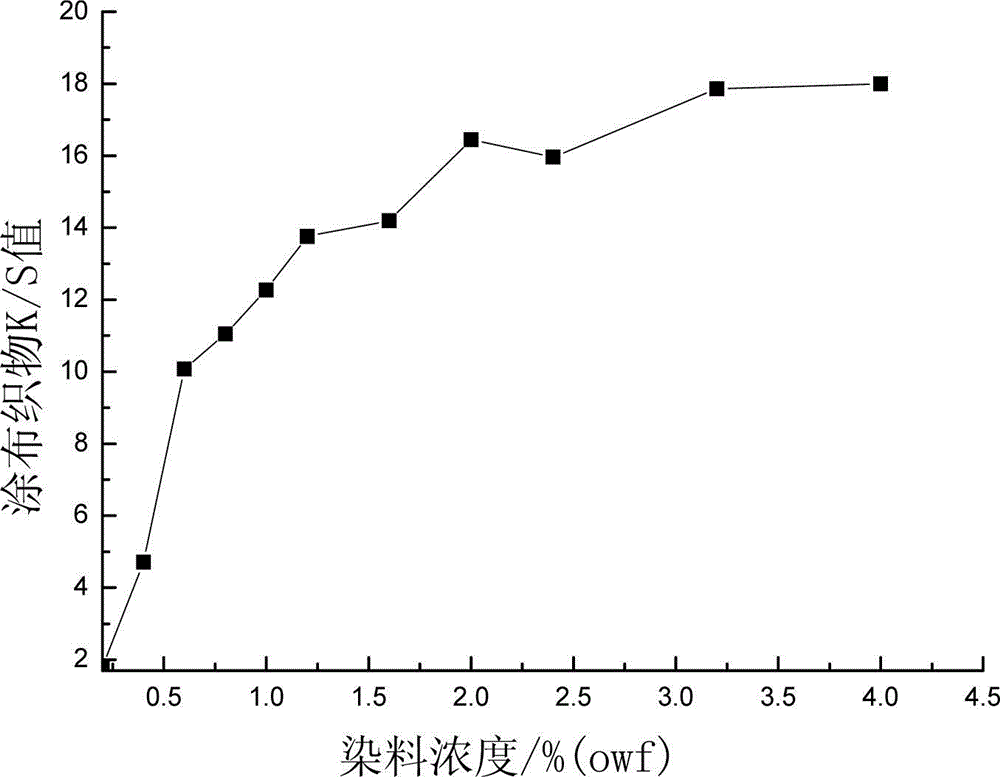

[0047] Step 1: Coating the fabric with reactive dyes by the dye coating method, and measuring the (K / S) of the coated fabric 0 ;

[0048] A. Prepared coating method to obtain 100% color fixation (K / S) of dyed sample 0 The dye solution:

[0049] Take 0.01g of reactive red B-2BF, 1g of salt and 0.5g of soda ash, and use 2ml of distilled water to make a slurry dye solution.

[0050] B. Coating the fabric with reactive dyes:

[0051] Spread 1g of pure cotton fabric evenly on a glass plate with a smooth surface, absorb the dye solution with a rubber dropper, apply all the dye solution evenly on the front and back sides of the fabric, and fix the color at 50°C for 40 minutes.

[0052] C. Determination of K / S value

[0053] After step B is completed, it is dried, and at a maximum absorption wavelength of 540nm, the K / S value of the fabric measured by an electronic computer color measuring and matching instrument is 8.19, which is (K / S) 0 .

[0054] Step 2. Determination after...

Embodiment 2

[0073] Step 1: Coating the fabric with reactive dyes by the dye coating method, and measuring the (K / S) of the coated fabric 0 ;

[0074] A. Prepared coating method to obtain 100% color fixation (K / S) of dyed sample 0 The dye solution:

[0075] Take 0.02g of reactive red B-2BF, 1g of salt and 0.5g of soda ash, and mix it with 2ml of water to make a slurry dye solution.

[0076] B. Coating the fabric with reactive dyes:

[0077] Spread 1g of pure cotton fabric evenly on a glass plate with a smooth surface, absorb an appropriate amount of dye solution with a rubber dropper, apply all the dye solution evenly on the front and back sides of the fabric, and fix the color at 50°C for 40 minutes.

[0078] C. Determination of K / S value

[0079] After step B is completed, it is dried, and at a maximum absorption wavelength of 540nm, the K / S value of the fabric measured by an electronic computer color measuring and matching instrument is 12.20, which is (K / S) 0 .

[0080] Step 2....

Embodiment 3

[0099] Step 1: Coating the fabric with reactive dyes by the dye coating method, and measuring the (K / S) of the coated fabric 0 ;

[0100] A. Prepared coating method to obtain 100% color fixation (K / S) of dyed sample 0 The dye solution:

[0101] Take 0.04g of reactive red B-2BF, 1g of salt and 0.5g of soda ash, and mix it with 2ml of water to make a slurry dye solution.

[0102] B. Coating the fabric with reactive dyes:

[0103] Spread 1g of pure cotton fabric evenly on a glass plate with a smooth surface, absorb the dye solution with a rubber dropper, apply all the dye solution evenly on the front and back sides of the fabric, and fix the color at 50°C for 40 minutes.

[0104] C. Determination of K / S value

[0105] After step B is completed, it is dried, and at a maximum absorption wavelength of 540nm, the K / S value of the fabric measured by an electronic computer color measuring and matching instrument is 17.58, which is (K / S) 0 .

[0106] Step 2. Determination after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com