Internal-focusing high power focusing lens

A focusing lens and high-power technology, applied in the field of focusing lenses, can solve the problems of difficulty in multi-beam high-energy lasers, inability to achieve precise focusing, and the inability of large-diameter focusing lenses to move accurately, achieving the effect of simple and compact structure, convenient and fast focusing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

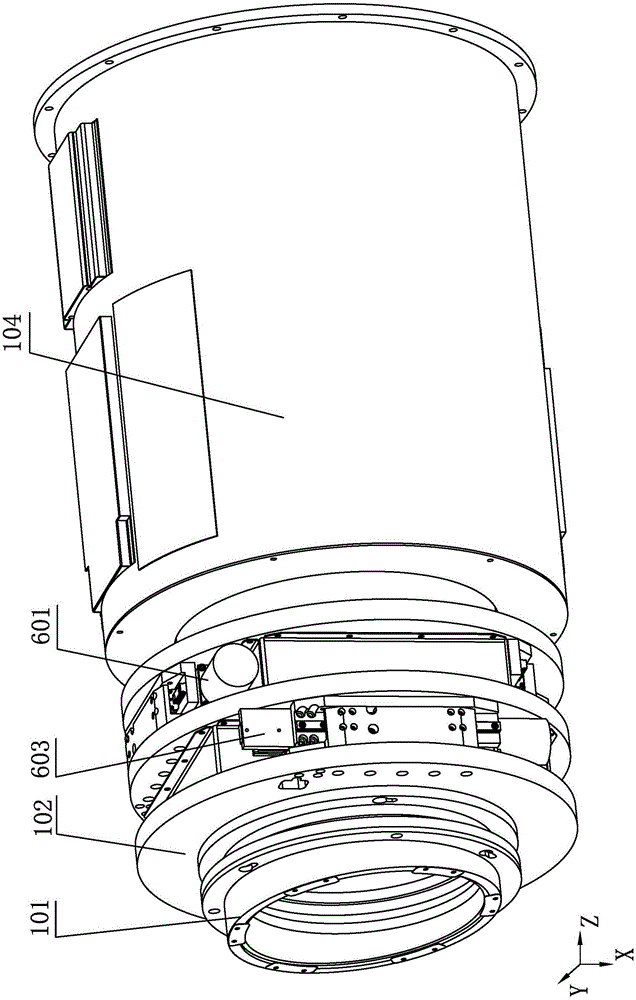

[0008] Specific implementation mode one: combine Figure 1-Figure 10 Explain that a focusable high-power focusing lens of this embodiment includes a lens shield assembly 101, a lens replacement unit assembly 102, an X-direction position adjustment assembly 603, a Y-direction position adjustment assembly 601, and a Z-direction position adjustment assembly 104;

[0009] The lens shield assembly 101 is installed on the lens replacement unit assembly 102, and the lens replacement unit assembly 102 is installed on the X-direction position adjustment assembly 603, and the X-direction position adjustment assembly 603 is used to drive the lens driving assembly 102 to move in the X direction, The X-direction position adjustment assembly 603 is installed on the Y-direction position adjustment assembly 601, the Y-direction position adjustment assembly 601 is used to drive the X-direction position adjustment assembly 603 to move in the Y direction, and the Y-direction position adjustment ...

specific Embodiment approach 2

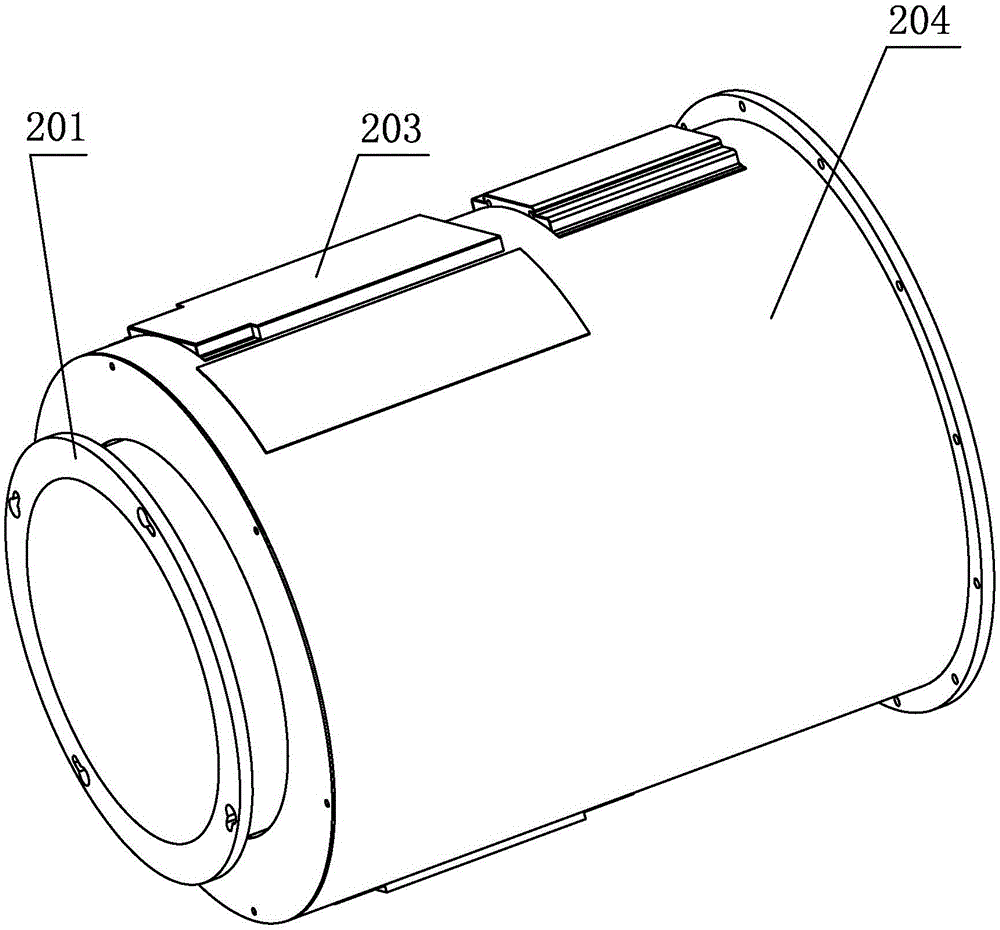

[0010] Specific implementation mode two: combination Figure 2-Figure 3 Explain that the Z-direction position adjustment assembly 104 of this embodiment includes a lens focusing lens barrel 201, a lens housing 204, and a drive assembly 403; the drive assembly 403 includes a motor 504, a motor base 503, a Z-direction screw pair, and a support plate 501;

[0011] The lens housing 204 is a cylindrical housing, the lens focusing lens barrel 201 and the driving assembly 403 are arranged in the lens housing 204, the motor 504 is installed on the motor base 503, and the motor base 503 is installed on the lens housing 204 to support The plate 501 is installed on the lens housing 204, the lead screw 506 of the Z direction lead screw pair is installed on the support plate 501 through the bearing seat 505, the output end of the motor 503 is connected with the lead screw 506 of the Z direction lead screw pair, and the Z direction lead screw The auxiliary screw nut 507 is connected with th...

specific Embodiment approach 3

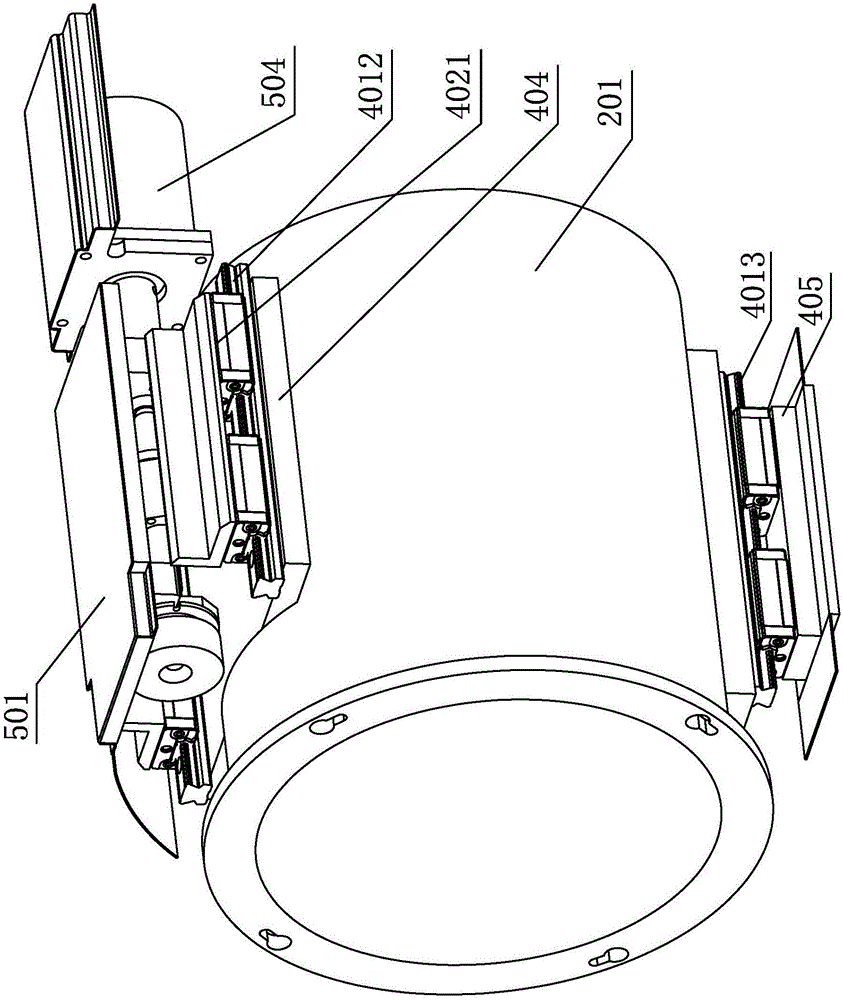

[0012] Specific implementation mode three: combination Figure 4 Note that the drive assembly 403 of this embodiment also includes a lower linear guide rail 4013, an upper guide rail base 404, a lower guide rail base 405, a lower slider base 4023, two upper linear guide rails 4012 and two upper slider bases 4021 ;

[0013] The lower slider base 4023 is installed on the lower part of the lens focusing lens barrel 201, the lower linear guide rail 4013 is installed on the lower part of the lower slider base 4023, the lower guide rail base 405 is installed on the lens housing 204, and the lower linear guide rail 4013 is slidably arranged On the lower guide rail base 405; the upper guide rail base 404 is installed on the top of the lens focusing lens barrel 201, and two upper linear guide rails 4012 are installed side by side along the axial direction of the lens focusing lens barrel 201 on the upper guide rail base 404. The upper slider bases 4021 are respectively connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com