High-precision friction compensation control method of double-frame magnetic levitation CMG frame system

A frame system and friction compensation technology, applied in the field of servo system control, can solve problems such as enhancing the robustness of external disturbance torque and difficult to guarantee TDC stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

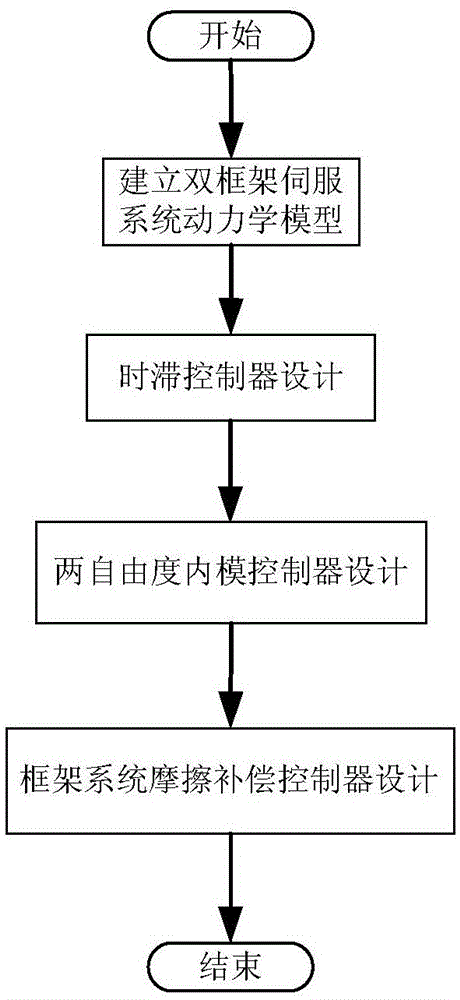

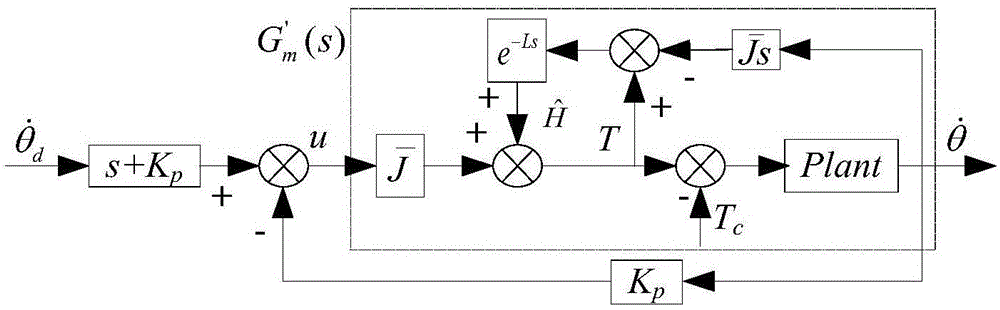

Method used

Image

Examples

specific Embodiment approach

[0055] (1) Establish the dynamic model of the double frame servo system

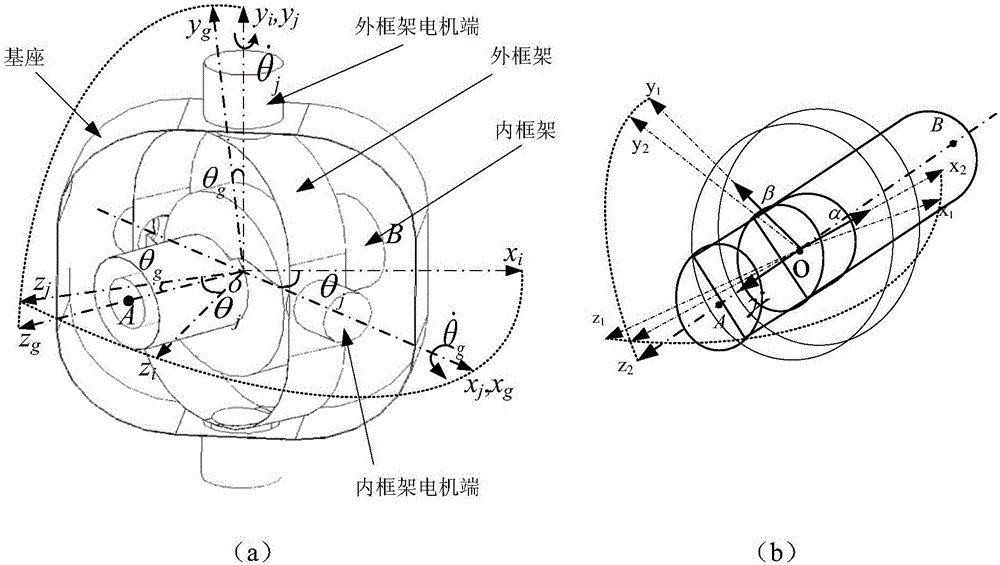

[0056] The coordinates of the maglev control moment gyro frame system and the high-speed rotor system are defined as figure 2 shown. ox i the y i z i is the inertial coordinate system, o is the geometric center of the gyroscope stator, x i In the initial state, coincide with the axis of the frame, and take the motor end of the frame as the positive direction, y i In the initial state, it points to the direction of the rotor rotation axis; ox j the y j z j It is the coordinate system of the outer frame, which is fixedly connected with the outer frame, coincides with the zero position system at zero position, and has relative inertial system with respect to y i The degree of freedom of the axis coincides with the inertial system in the initial state; ox g the y g z g It is the coordinate system of the inner frame, fixedly connected with the inner frame, relative to the outer frame system with r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com