Power tube driving integrated circuit

A technology for driving integrated circuits and integrated circuits, which is applied in the direction of electrical components, electronic switches, pulse technology, etc., can solve the problems of power tube burnout, slow driving speed, and insufficient integration, so as to reduce costs, improve machine reliability, Effect of large current drive capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

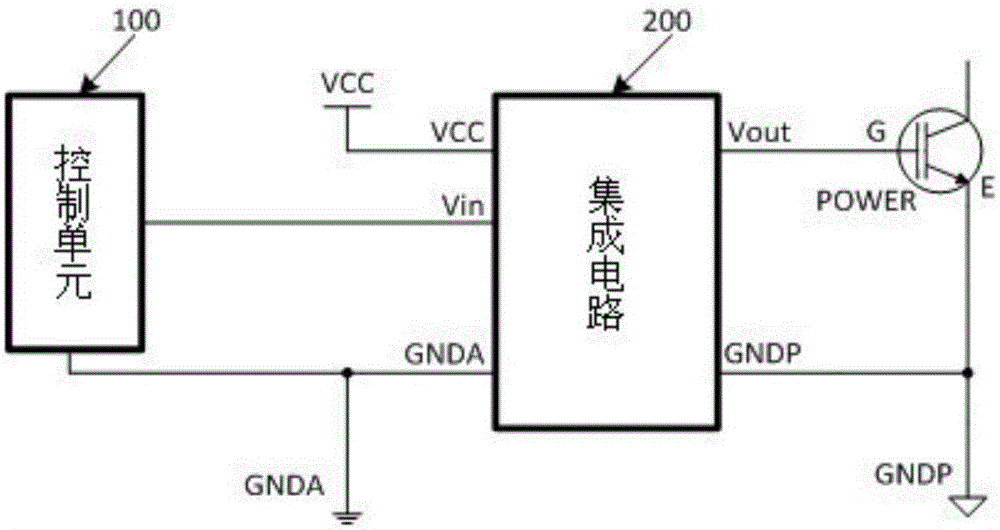

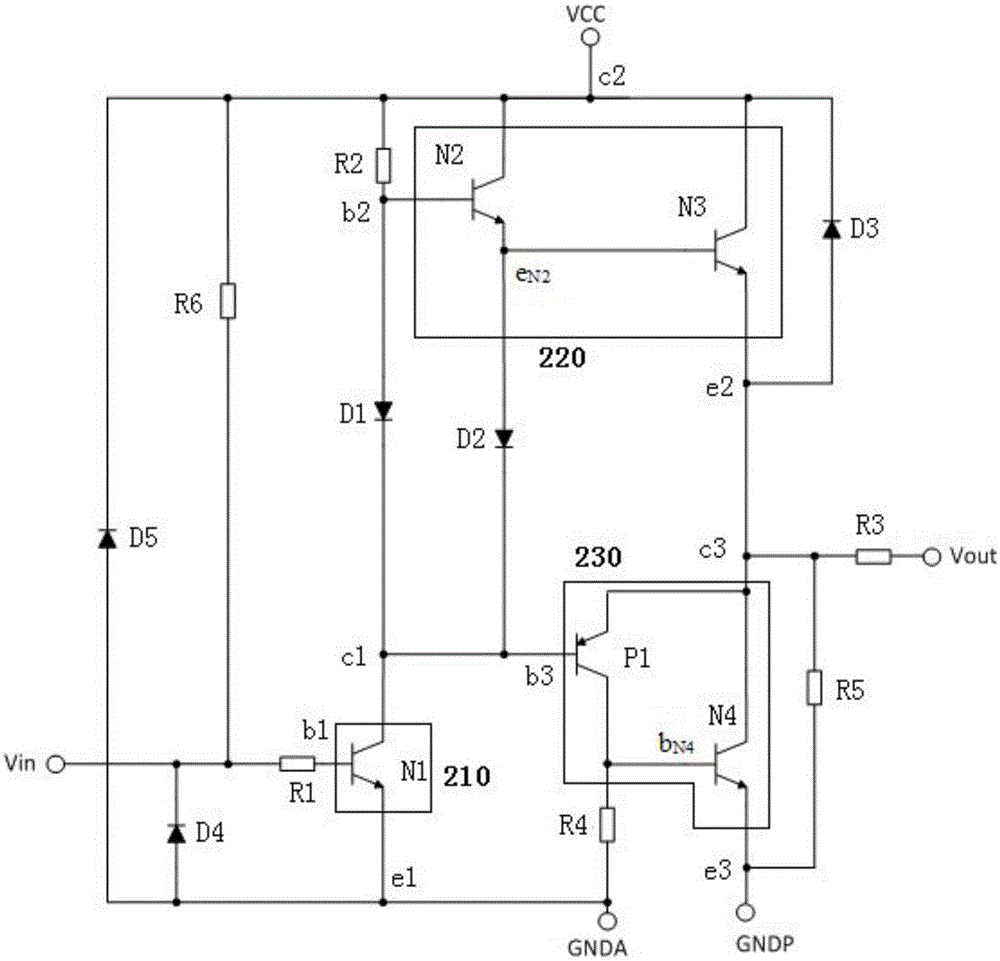

[0028] Such as Figure 1-2 As shown, the present invention provides a power tube driving integrated circuit, the signal input terminal Vin of the integrated circuit 200 is connected to the control unit 100 to receive the driving signal from the control unit for driving the power tube, and the integrated circuit 200 The signal output terminal Vout is connected to the power tube POWER, so as to switch the power tube on and off under the action of the driving signal, wherein the integrated circuit 200 is provided with a ground wire connected to the control unit on the signal input side. The connected control ground terminal GNDA is provided with a power ground terminal GNDP electrically connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com