A uniform gas distribution device for tower-type gas-liquid contact equipment and its application

A gas-liquid contact and gas distribution device technology, applied in the field of chemical engineering, can solve problems such as uneven distribution of bubbles, and achieve the effects of easy maintenance and replacement, stable operation, and high uniformity of gas distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

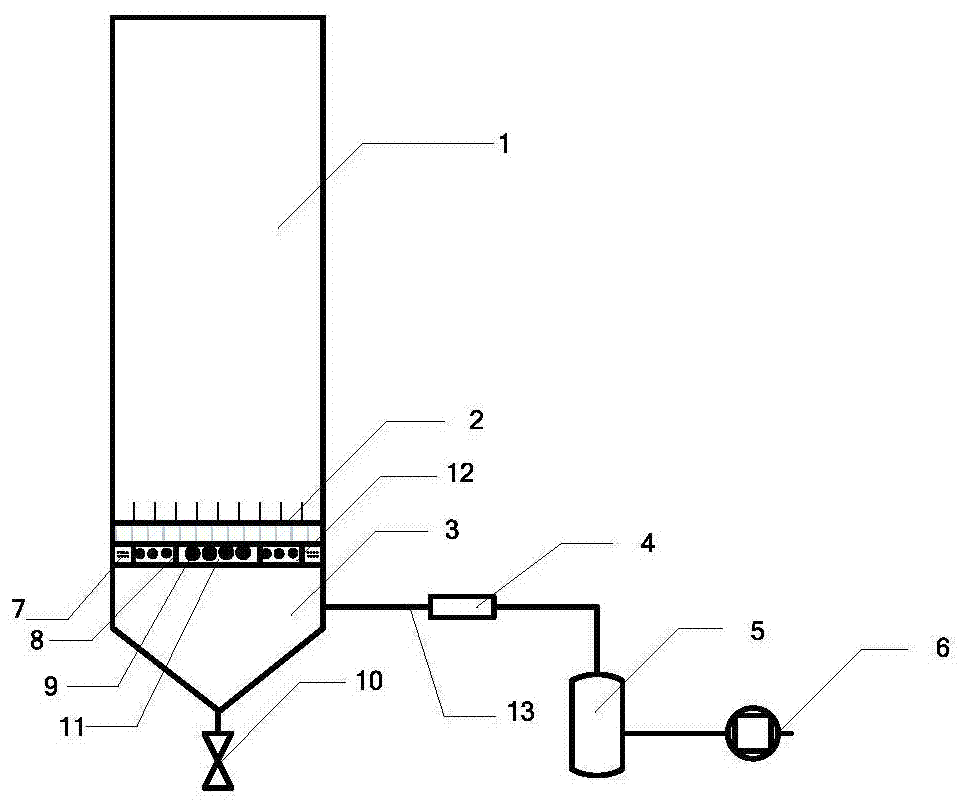

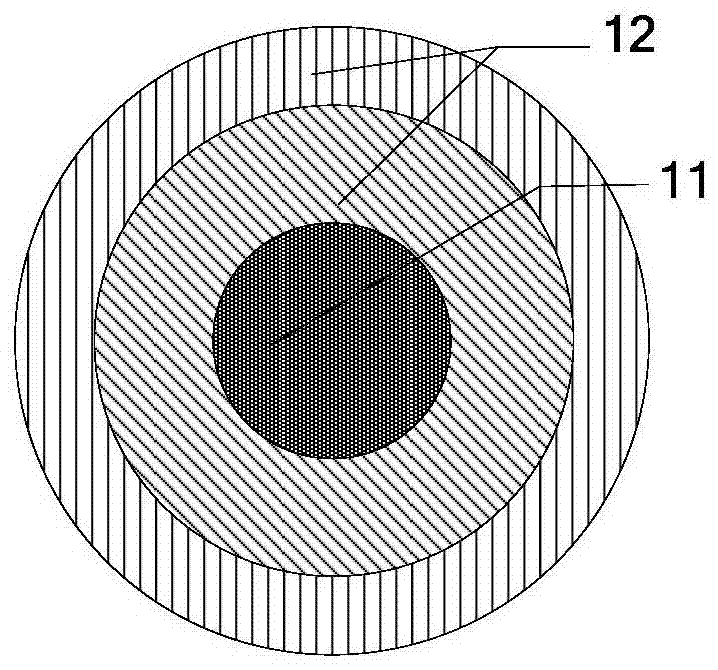

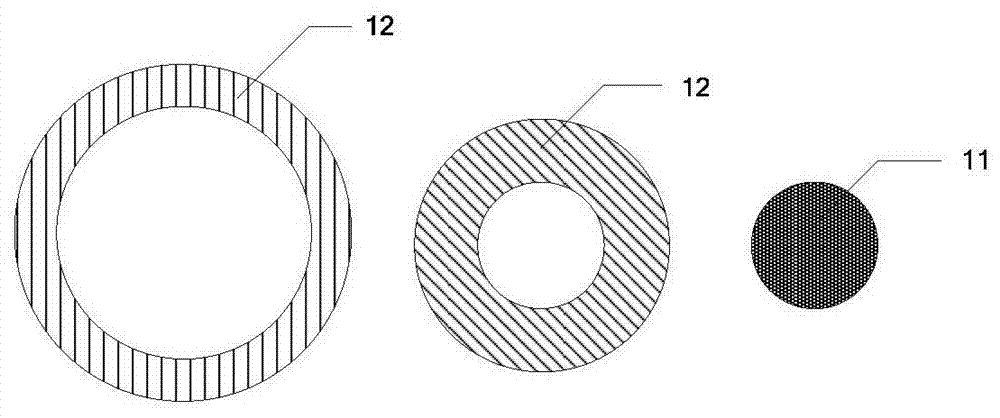

[0101] Such as figure 1 As shown, the present embodiment takes 3 hollow cylinders as an example to manufacture a pilot-scale solvent air flotation tower. The tower body size is: the height of the column tower body 1 is 3000mm, and the diameter of the column tower body 1 is 600mm. The base body of the gas distribution plate 2 is processed from a stainless steel plate with a thickness of 6mm. The outer edge of the gas distribution plate 2 is sealed and connected to the lower part of the column tower body 1. The thickness of the gas distribution plate 2 is 10 mm, and the inner diameter of the vertical channels opened on the gas distribution plate 2 is 1 mm. 5% of the total area of the base of the air distribution disc 2 . The length of the small straight tube inserted into the vertical channel is 11 mm, the diameter is 1 mm, and the small round tube is 5 mm higher than the base of the convex gas distribution disk 2 . The bottom surface of the gas distribution plate 2 is provi...

Embodiment 2

[0104] Except that the bottom surface of the gas distribution plate 2 is provided with 4 hollow cylinders 8 to manufacture a pilot-scale solvent air flotation tower, the thickness of the gas distribution plate is 20 mm, and the inner diameter of the vertical channels opened on the gas distribution plate 2 is 2 mm. The total area of holes in the channels accounts for 10% of the total area of the base of the gas distribution plate 2, the small round straight tubes are 10 mm higher than the base of the convex gas distribution plate 2, and the thickness of the resistance layer 7 is from 20 mm along the radial direction of the cross-section of the tower body from the inside to the outside. Outside gradually increases to 100mm, other structure and operation are all the same as the solvent air flotation tower in embodiment 1, can obtain the bubble number of 5mm in tower body cross-section and account for more than 95% of the total bubble number of generation by this device, And on...

Embodiment 3

[0106] Except that the bottom surface of the gas distribution plate 2 is provided with 30 hollow cylinders 8 to manufacture a pilot-scale solvent extraction tower, the thickness of the gas distribution plate is 2 mm, and the inner diameter of the vertical channels opened on the gas distribution plate 2 is 4 mm. The total area of the holes accounts for 20% of the total area of the gas distribution disk 2 substrates, and the small round straight pipe is higher than the substrate 20mm of the convex gas distribution disk 2. Other structures and operations are the same as those of the solvent air flotation tower in embodiment 1. Through the device, the number of bubbles of 2 mm can be obtained on the cross-section of the tower body, accounting for more than 95% of the total number of generated bubbles, and the number of bubbles is the same on the cross-section of the tower body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com