A flat solid oxide fuel cell connector and cell stack

A solid oxide, fuel cell technology, used in fuel cells, electrical components, circuits, etc., can solve the problems of overall battery performance, poor thermo-mechanical stability, poor airflow distribution uniformity, etc., to improve overall performance and thermo-mechanical stability. Stability, improved battery performance, and improved airflow distribution uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

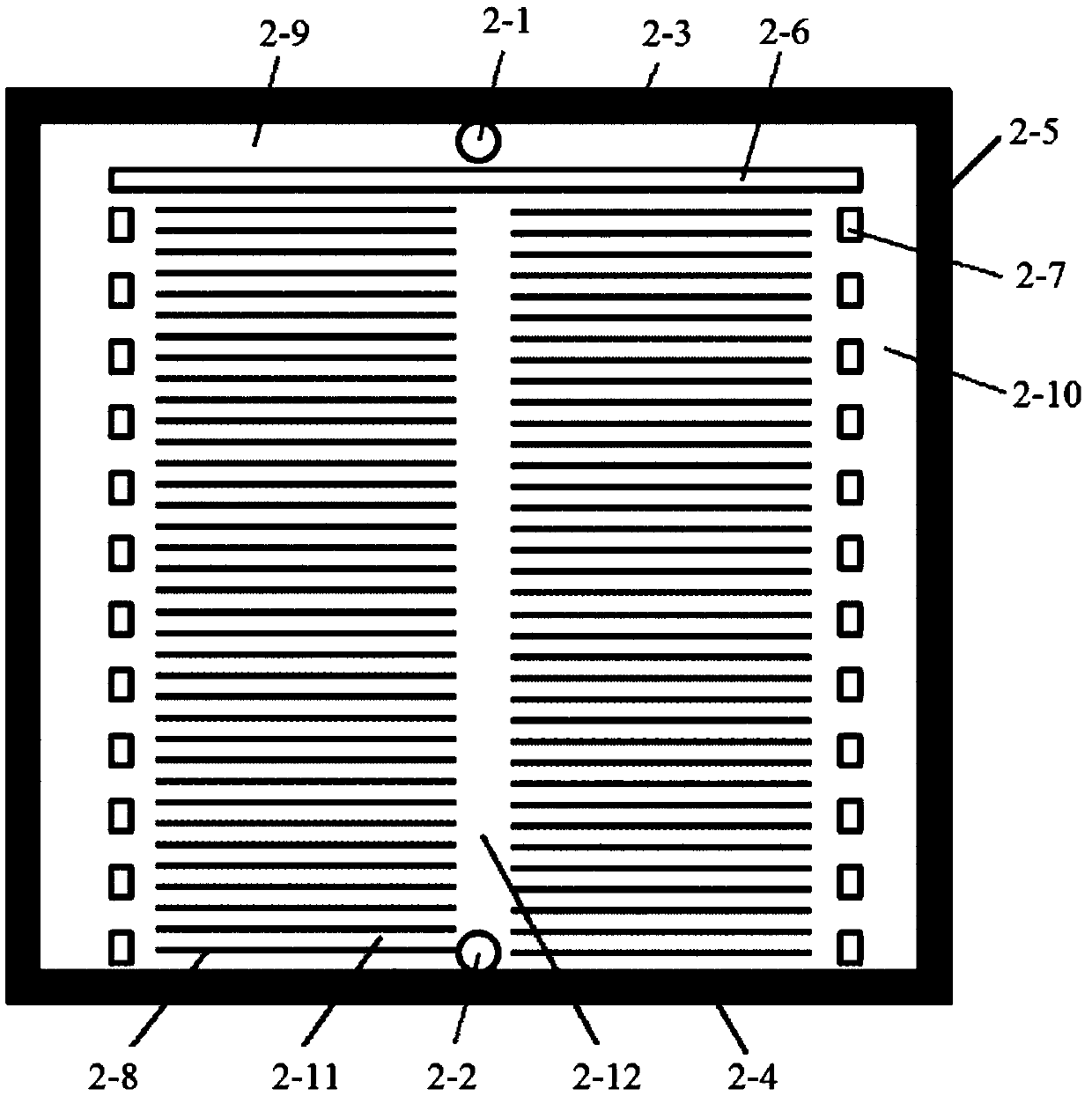

[0027] Such as figure 2 As shown, a flat-type solid oxide fuel cell connecting piece of the present invention includes a square connecting plate, and the connecting plate is made of ferritic stainless steel material, which has good electrical conductivity, large thermal conductivity, and expansion coefficient Small, good oxidation resistance, excellent stress corrosion resistance, can be applied in the working temperature range of 800-1000 ° C, the connecting plate includes the upper edge 2-3, the lower edge 2-4 and the two side edges 2-5, An air inlet 2-1 is arranged on the top of the connecting plate, and an air outlet 2-2 is arranged on the bottom of the connecting plate, and both the air inlet 2-1 and the air outlet 2-2 are circular ports .

[0028] A baffle 2-6 is provided on the top of the connecting plate close to the air in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com