Screwed pipe forming machine

A technology for forming machines and threaded pipes, used in thread trimmers, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of single function, poor fixture stability, uneven thickness of the threaded wall, etc., to achieve accurate positioning and extended use. Duration, avoid the effect of uneven wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

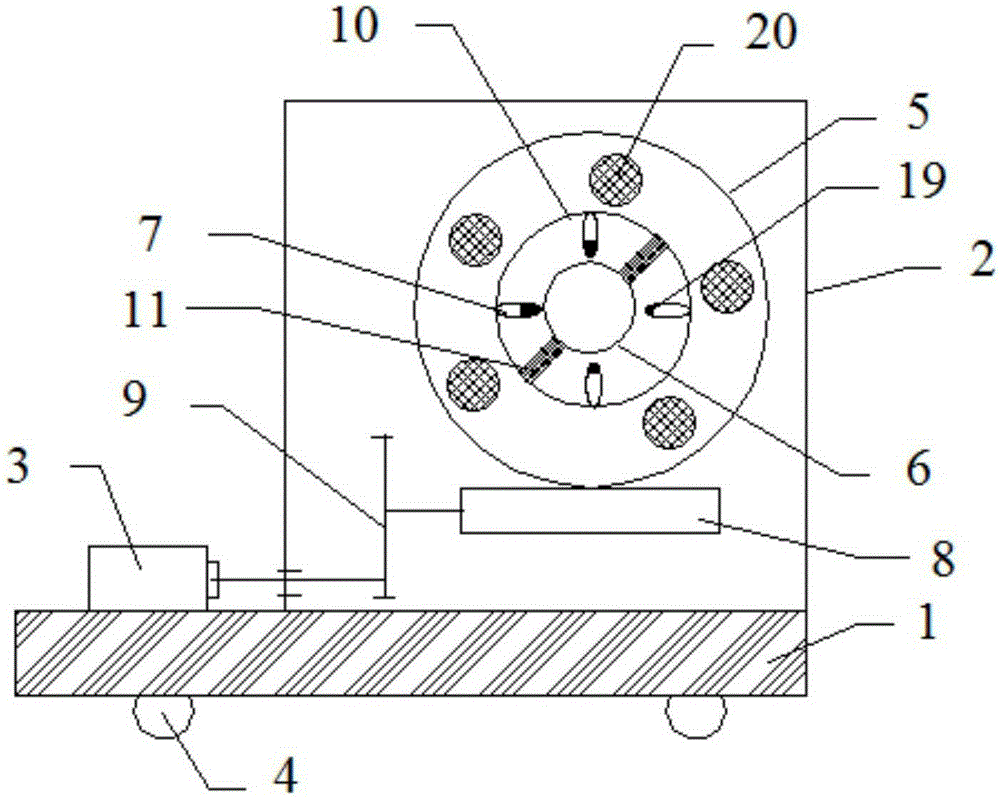

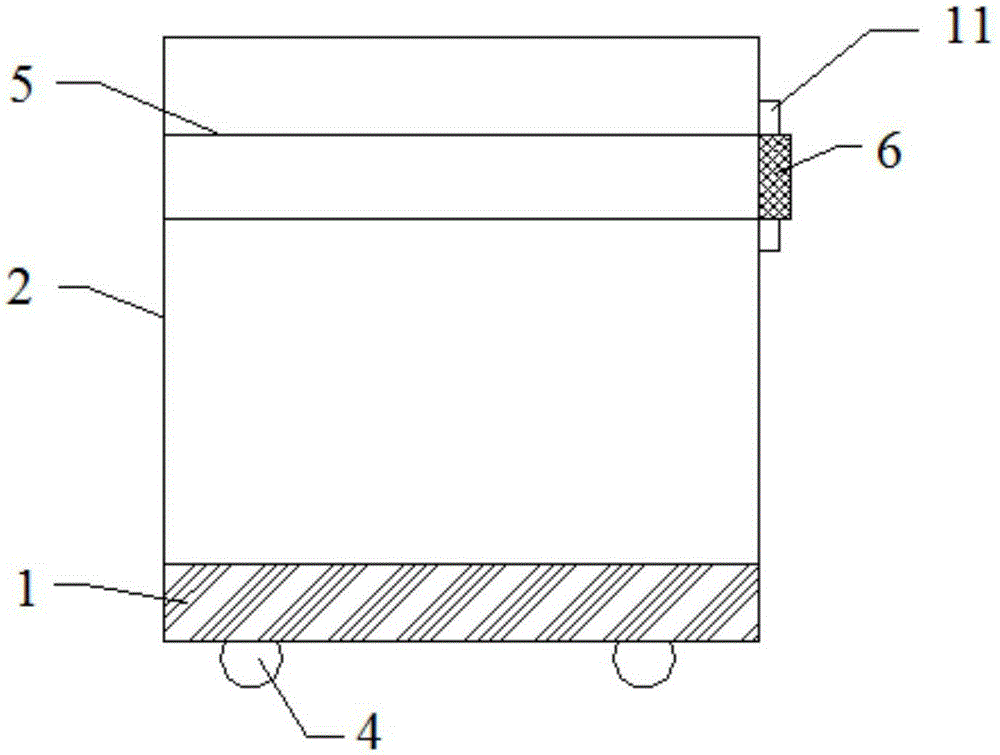

[0015] figure 1 The specific embodiment of the present invention is shown: a threaded pipe forming machine, including a base 1, a casing 2, a motor 3 and a forming structure, the casing 2 is arranged on the base 1, and the base 1 is provided with universal wheels 4. The molding structure is arranged in the casing 2, and the molding mechanism includes a worm wheel 5, a clamping device and a thread cutting head 7, and the worm wheel 5 is connected with the motor 3 through a worm 8 and a gear 9, and the worm wheel 5 is A through hole 10 is provided, the clamping device is arranged at the mouth of the through hole 10 through a support plate 11 , and the thread cutting heads 7 are arranged along the inner wall of the through hole 10 .

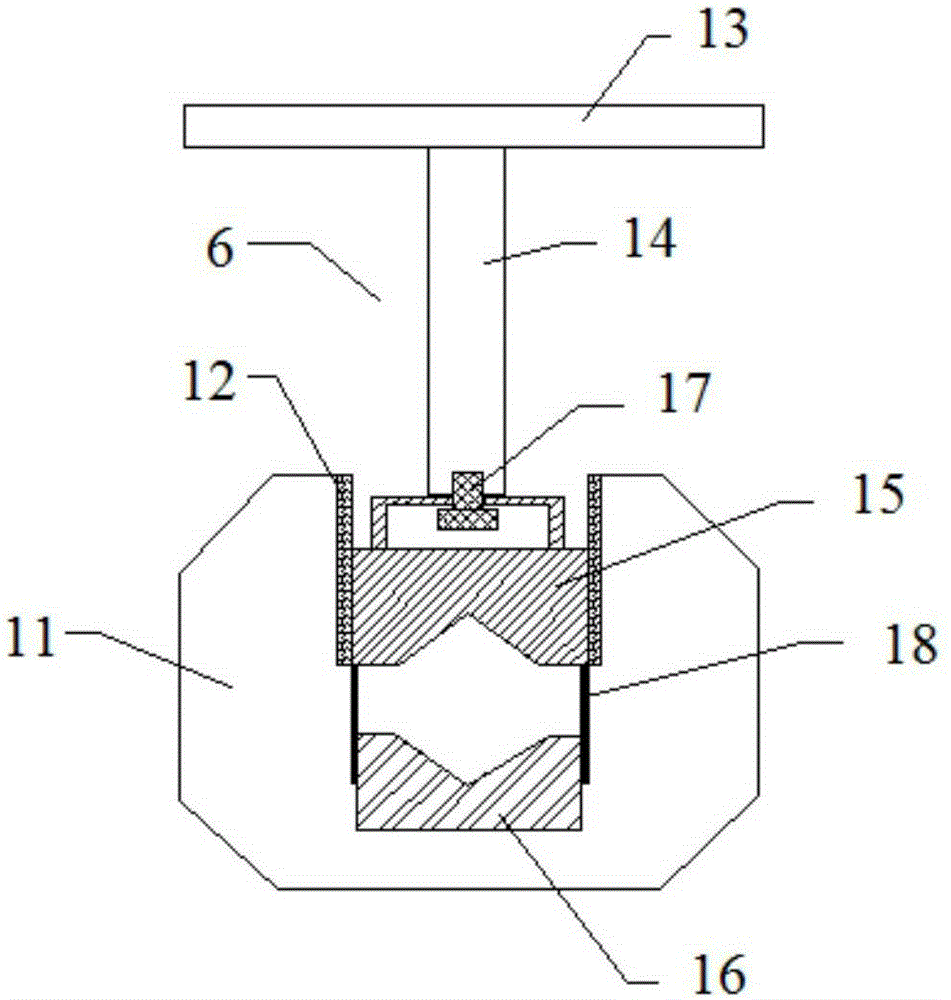

[0016] In addition, if figure 2 As shown, the clamping device is set as an automatic centering clamping device 6, the automatic centering clamping device 6 moves on the support plate 11 through the guide rail 12, and the automatic centering clampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com