A kind of solar cell printing screen plate and plate making method thereof

A technology of solar cells and printing screens, applied in printing, printing machines, printing plate preparation, etc., can solve the problems of not easy to drop ink, difficult to print, easy to block printing, etc., to increase ink penetration, reduce difficulty, and improve production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

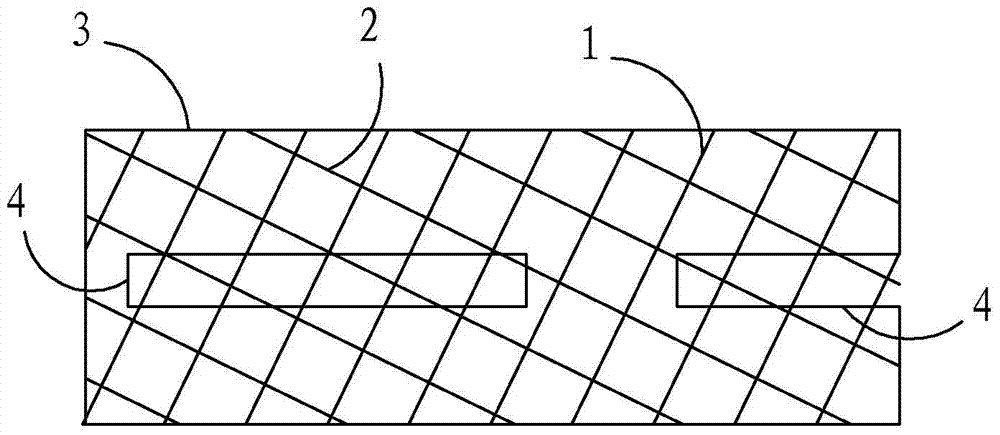

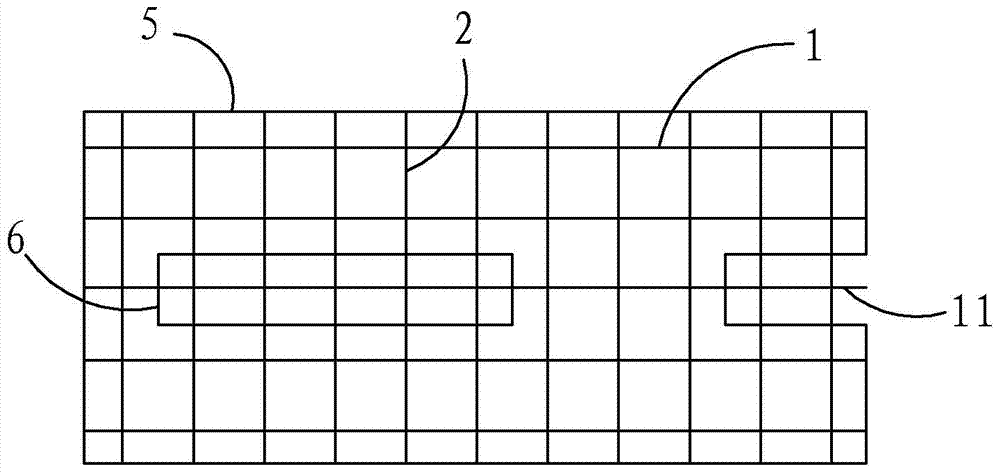

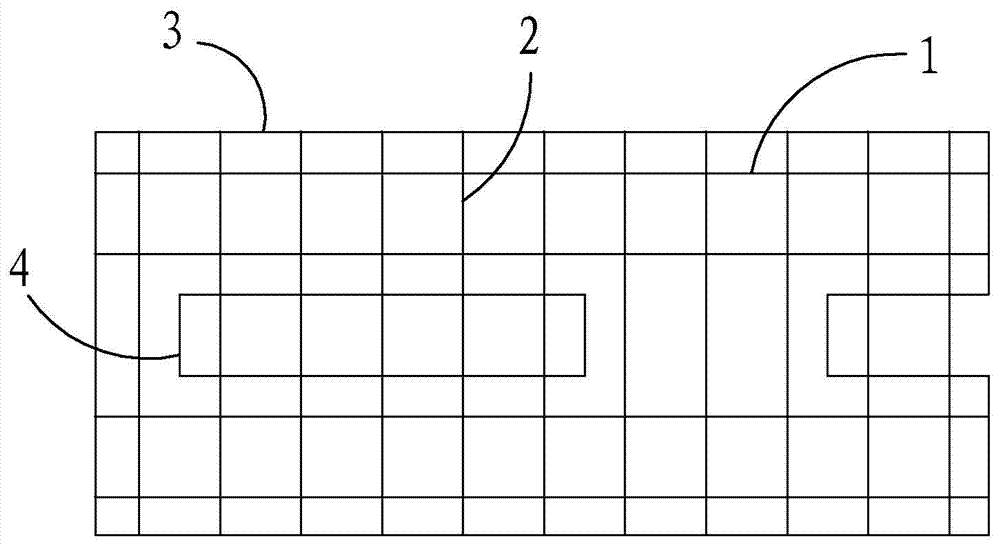

[0023] Embodiment one: see attached image 3 As shown, a solar cell printing screen screen plate, which includes a screen body woven into warp threads 1 and weft threads 2 and a rectangular aluminum frame (not shown in the drawings) that fixes the four sides of the screen body, warp threads 1 The upper surface of the wire mesh body is uniformly provided with a layer of cured photosensitive adhesive layer 3, and the photosensitive adhesive layer 3 is distributed with at least one row of rectangular through holes 4 intermittently distributed along straight lines parallel to each other. The straight line where the rectangular through hole 4 is located is parallel to the warp 1, and the projection of the rectangular through hole 4 on the screen body has no intersection point with the warp 1.

[0024] In this embodiment, at least one warp 1 is removed from the screen body, and the rectangular through holes 4 are distributed along the straight line where the removed warp 1 is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com