Motor vehicle seat

A technology for motor vehicles and seats, which is applied to vehicle seats, vehicle parts, special positions of vehicles, etc., and can solve the problems of complex manufacturing process of the headrest mounting seat, poor adaptability of the headrest mounting seat, and unsmooth plugging and unplugging of the headrest, etc. Problems, achieve the effect of reducing welding time and heat-affected zone, reducing welding surface, and reducing process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

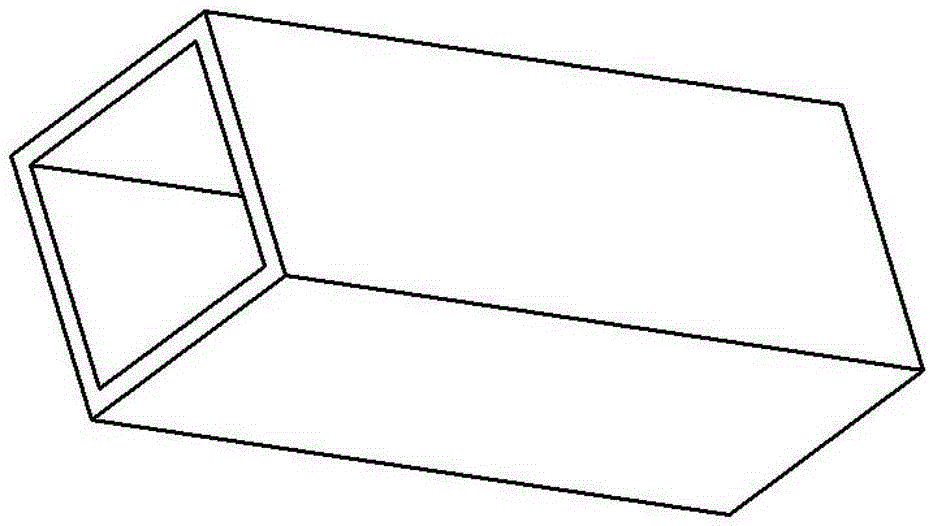

[0022] figure 1 It is a schematic diagram of a square seat body in the prior art. This seat body and the backrest main frame tube 7 are connected by welding; The welding surface is flattened so that the two welding surfaces can be in better contact, so the process requirements are relatively high and complicated, and the entire mounting seat is easy to be burned due to the large amount of welding and the long welding time during welding. Other issues described in the technique.

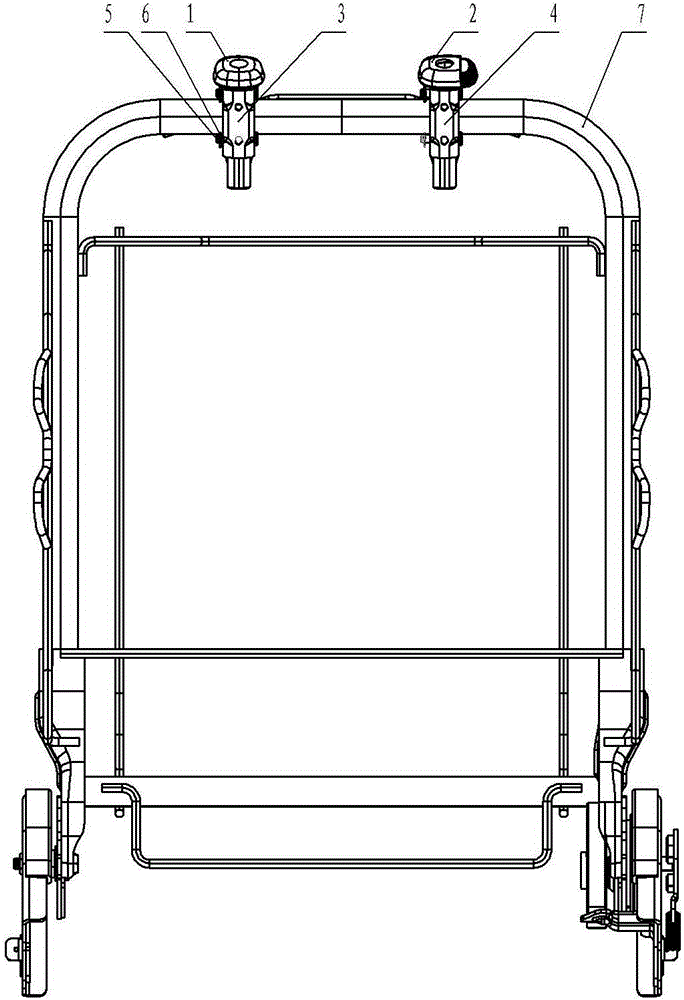

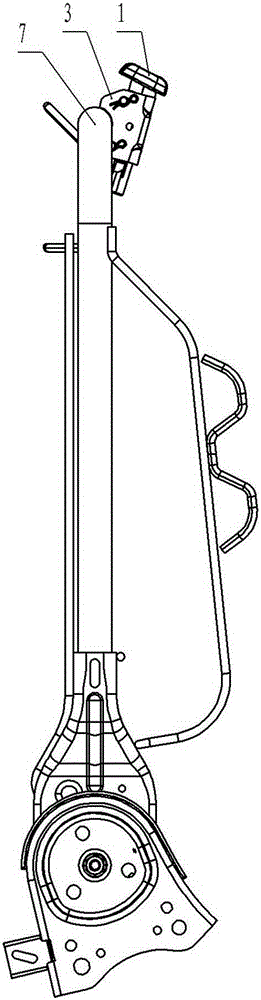

[0023] figure 2 , image 3 and Figure 4 Shown is the schematic diagram of the skeleton structure of the motor vehicle seat of the present invention, including two inserting rod sleeve mounting seats welded on the backrest main frame tube 7, inserting rod sleeves are housed in the inserting rod sleeve mounting seats, two inserting rods One of the sleeves is a card-free rod sleeve 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com