Vehicle for mine transportation

A technology for mine transportation and vehicles, which is applied to vehicle parts, transportation and packaging, and the upper structure of trucks, etc. It can solve the problems that the truck load cannot be changed freely, tire wear, and poor conditions in the workplace, so as to reduce the number of trucks. Effects of tire wear, improvement of road conditions, and reduction of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

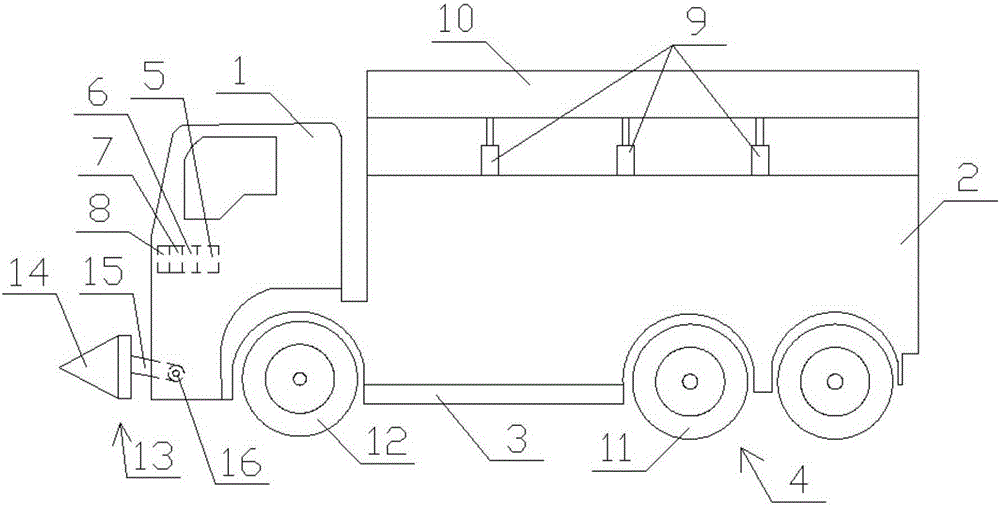

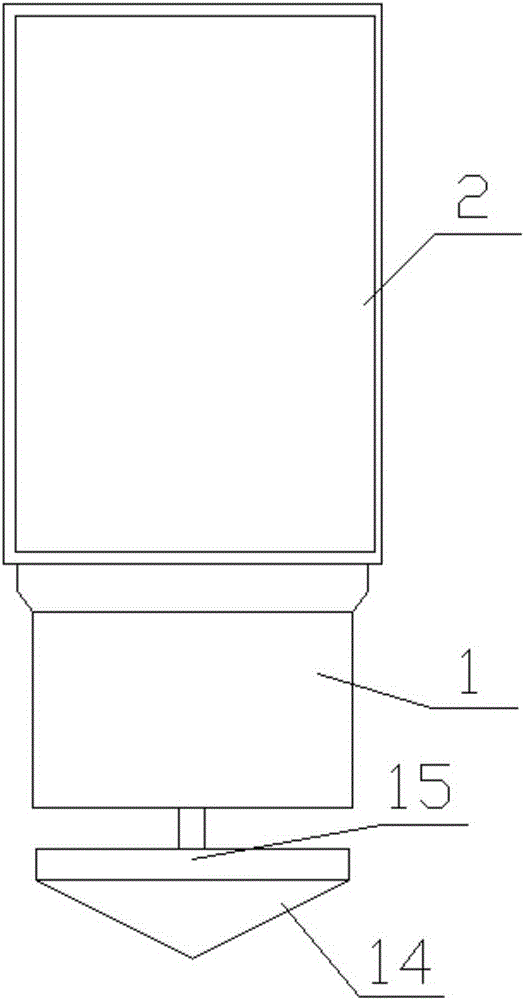

[0011] Such as figure 1 , figure 2 As shown, a vehicle for mine transportation includes a headstock 1, a compartment 2, a chassis 3 and wheels 4; the wheels 4 include rear wheels 11 and front wheels 12; the headstock 1 is provided with a hydraulic control device 5 The hydraulic control device 5 includes a lift solenoid valve 6, a hydraulic controller 7 and a travel switch 8, the travel switch 8 is connected to the hydraulic controller 7, and the hydraulic controller 7 is connected to the lift solenoid valve 6; 2. A movable baffle 10 is arranged on each of the upper four sides, and three hydraulic cylinders 9 for driving the movable baffle 10 to move up and down are connected under each movable baffle 10; Protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com