Repairing method for honeycomb sandwich structure

A technology of honeycomb interlayer and honeycomb, which is applied in the field of aircraft repair or rework, can solve the problems of heavy weight gain of structural parts, affecting the performance of parts, and heavy packing weight, etc., and achieve the effect of reducing structural weight and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0030] A kind of honeycomb sandwich structure repair method its principle is

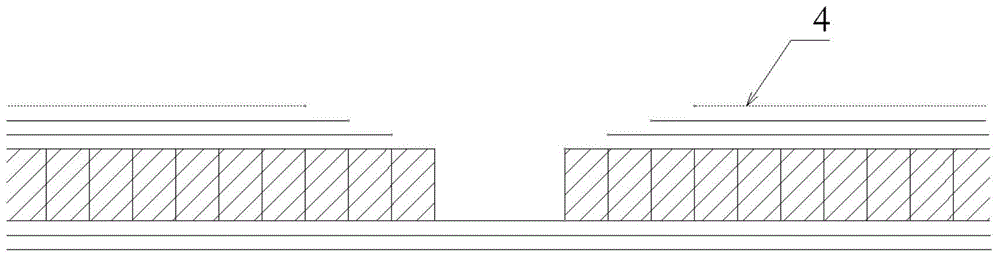

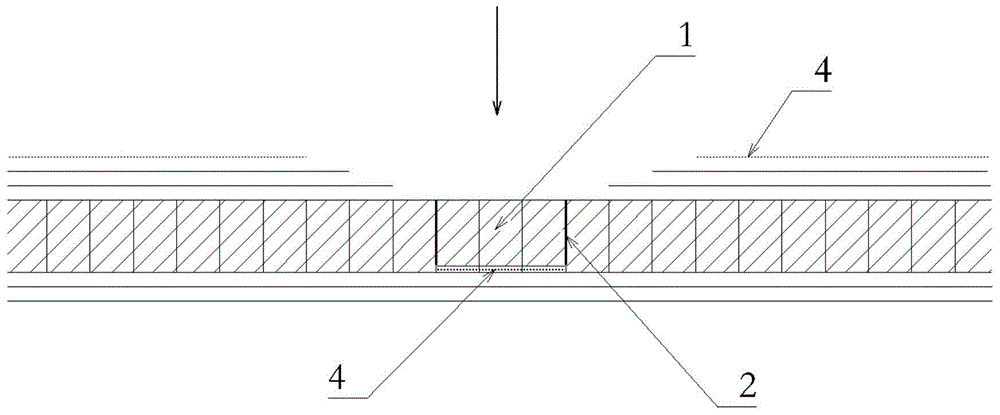

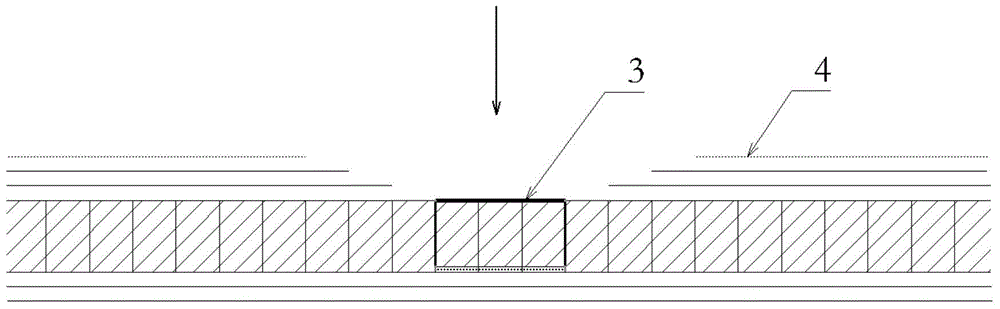

[0031] Combine below figure 1 , figure 2 and image 3 , the specific implementation process of the honeycomb sandwich structure repair method of the present invention is further described, and its specific process is as follows:

[0032] Step 1: Removing the layup and damaging the honeycomb

[0033] The ply to remove flat or slightly contoured areas is done using a pneumatic sanding tool with a 60 grit sanding disc, followed by hand sanding with approximately 320 grit sandpaper; after the ply is removed, the honeycomb must be pneumatically sanded until it is close to the underside of the honeycomb 0.5-1mm of the panel. Usually this area is the adhesive film; the remaining honeycomb must be sanded with 150-grit sandpaper or finer by hand or automatically, being careful not to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com