Cloth bag packaging machine

A packaging machine and cloth bag technology, applied in the field of logistics packaging, can solve the problems of complex production process, large power consumption and serious problems, and achieve the effects of reducing environmental pollution, facilitating recycling and storage, and reducing occupied space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

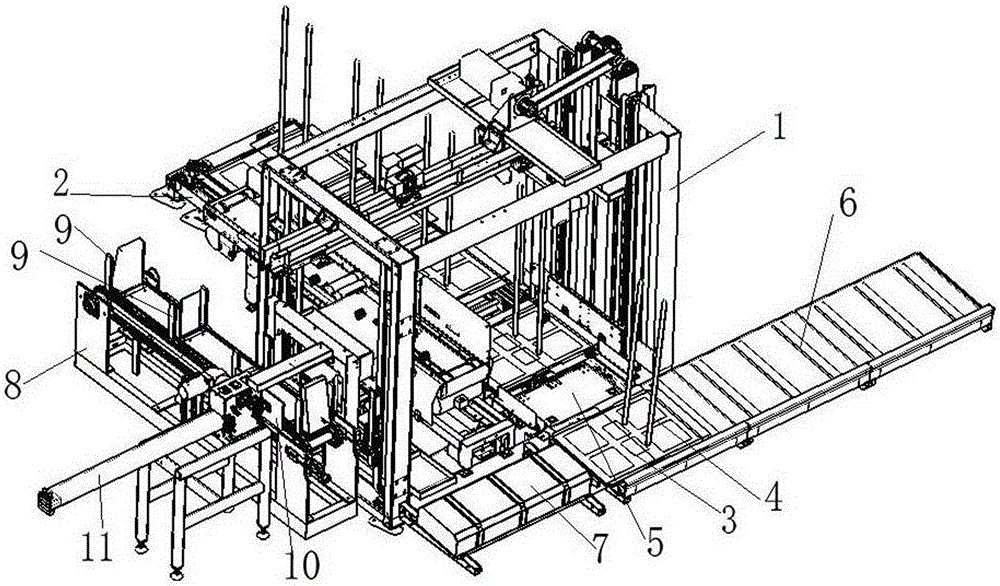

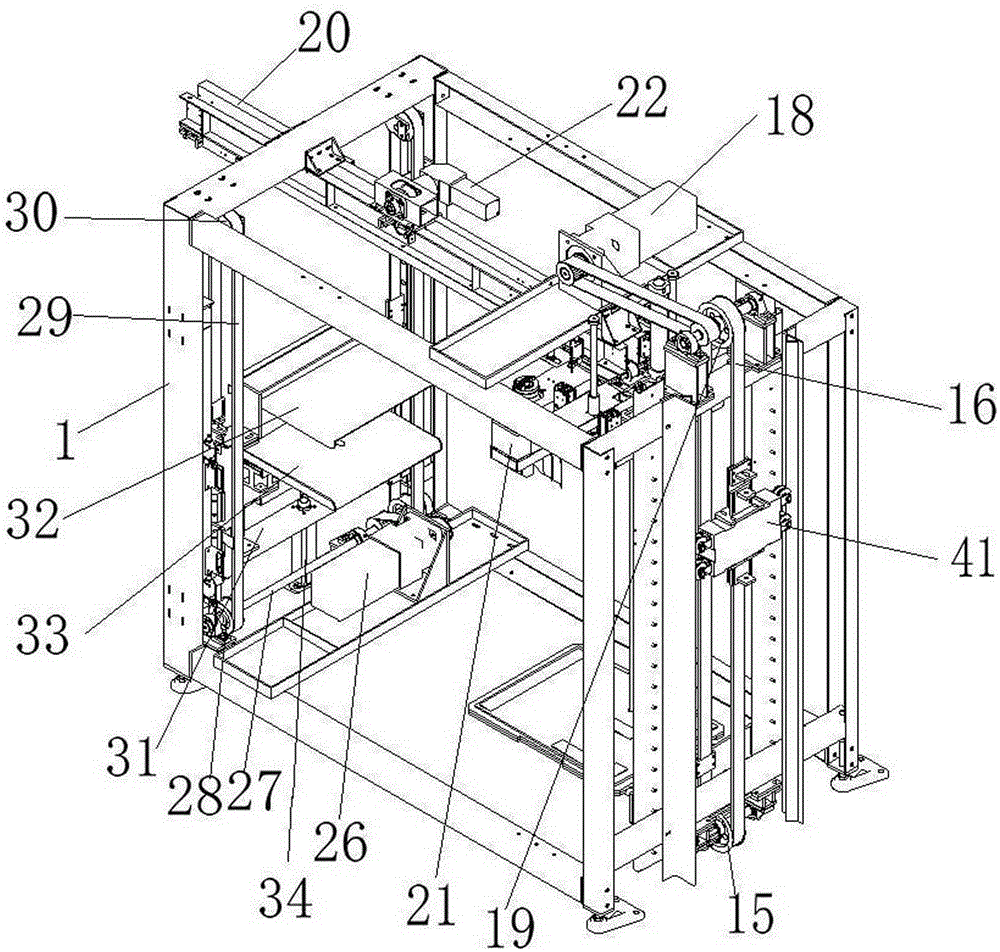

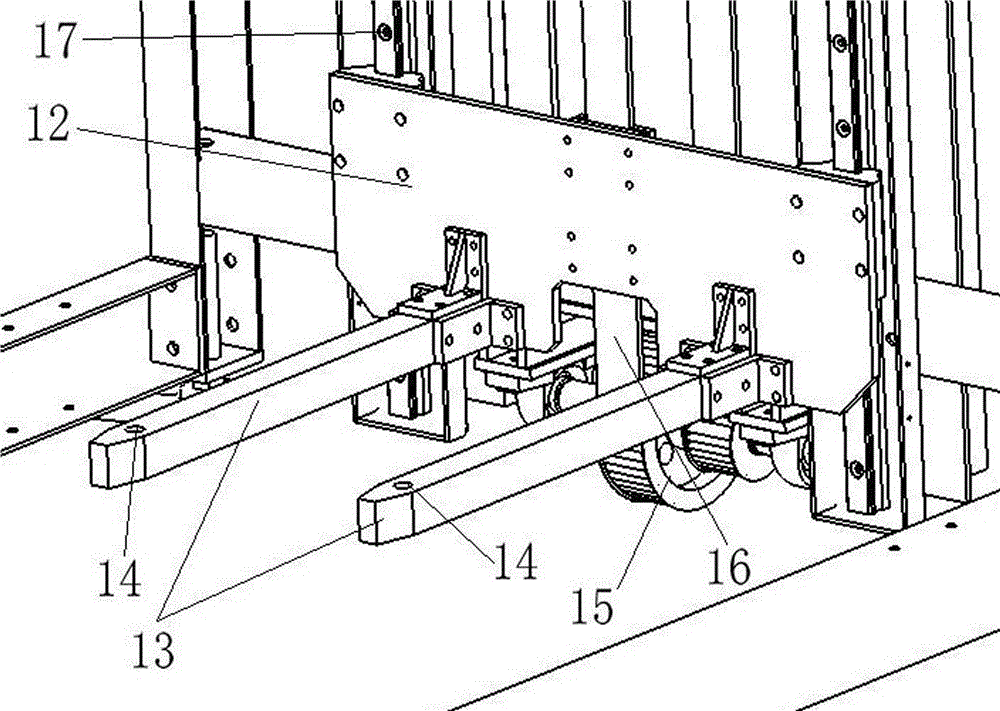

[0045] Attached below figure 1 To attach Figure 7 The present invention will be further described.

[0046] as attached figure 1 As shown, the cloth bag packaging machine of the present invention includes: a frame 1; a tray 3, which is located in the frame 1, and is used to stack a number of cloth bags that are stacked up and down in a pressed state; a tray lifting device is installed on the frame 1 , which is used to drive the tray 3 to move up and down in the longitudinal direction; the bag carrying device is installed on the frame 1, and is used to absorb the upper surface of a cloth bag at the uppermost end of the tray 3 and lift it to a certain height, so that the cloth bag is in a longitudinally opened state; The horizontal bag support device is installed on the frame 1, and it is used to lift the cloth bag at a certain height by the bag carrying device to stretch it in place; the vertical bag support device is installed on the frame 1, and it is used to support the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com